Environment-friendly wall surface grinding device for building construction and building construction method

A kind of construction and environmental protection technology, applied in the direction of grinding/polishing safety device, machine tool suitable for grinding workpiece plane, grinding machine, etc., can solve the problems of low practicability, heavy workload, time-consuming and labor-intensive, etc., and achieve reasonable structure , Fit tightly, improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

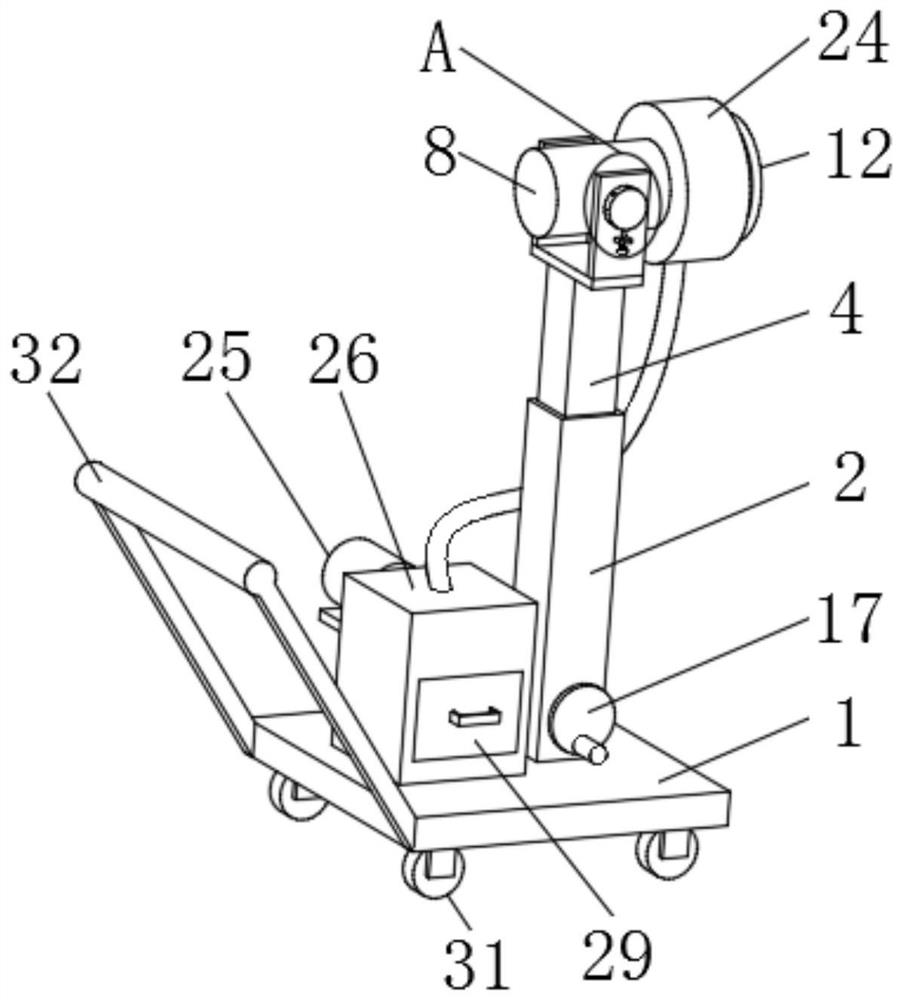

[0042] Example: Reference Figure 1-6 As shown, this embodiment discloses an environment-friendly building construction wall smoothing device, including a base 1, the base 1 can be any base structure in the prior art, such as a metal base, and will not be repeated here .

[0043] A support column 2 is fixed on the top of the base 1, and the support column 2 may be any metal vertical column in the prior art, which is welded to the top of the base 1 for fixing.

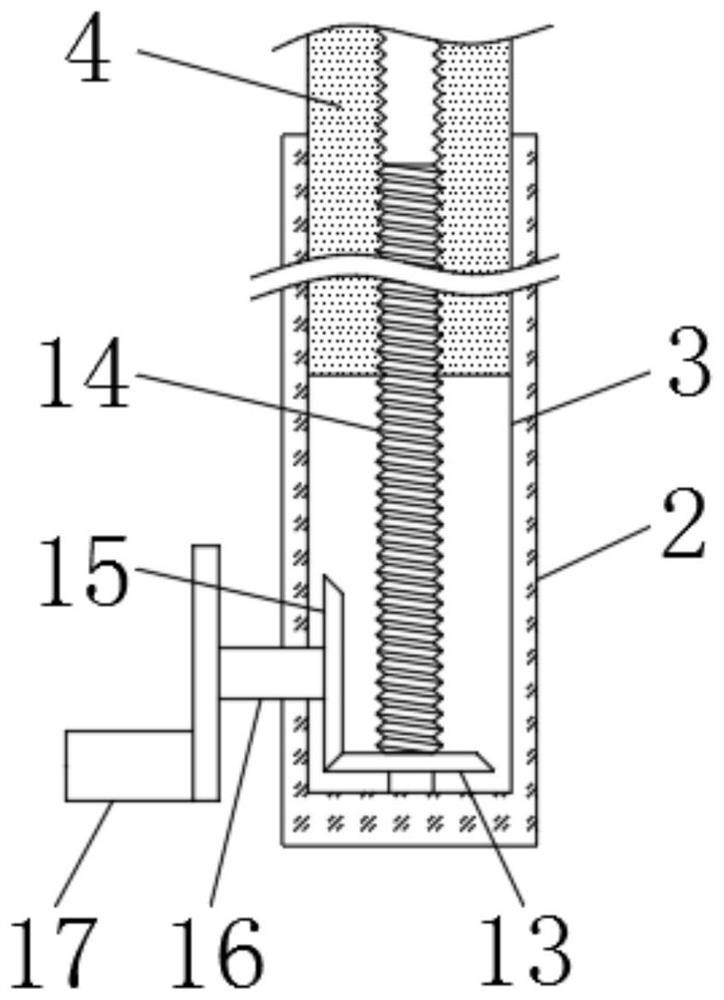

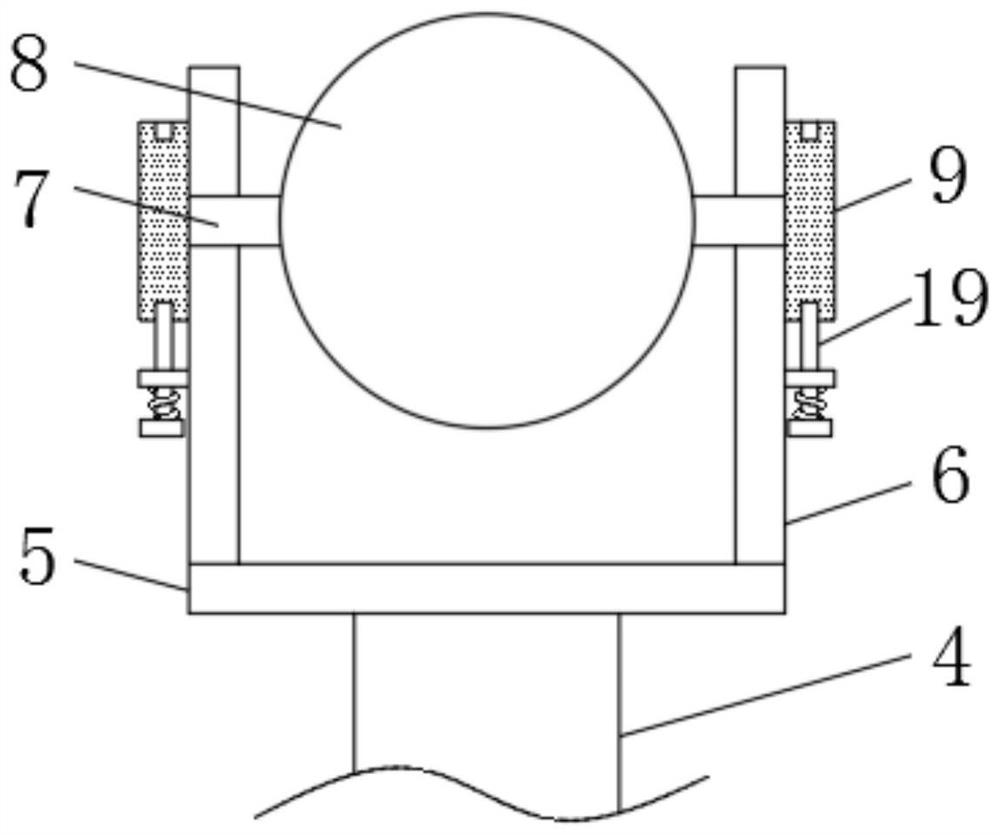

[0044] The top of the support column 2 is provided with a telescopic groove 3, and a telescopic column 4 that can move up and down is installed in the telescopic groove 3. A moving mechanism is arranged on the telescopic column 4, and a horizontal plate 5 is fixed on the top of the telescopic column 4. The horizontal plate 5 Two vertical plates 6 are fixedly arranged on the top of the top, and a rotating shaft 7 is installed on the side where the two vertical plates 6 are close to each other. Any type of motor 8 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com