A kind of wooden slide surface grinding treatment equipment

A technology for processing equipment and slides, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of health hazards, high labor intensity of wooden slides, low grinding efficiency of wooden slides, etc. The effect of sanding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

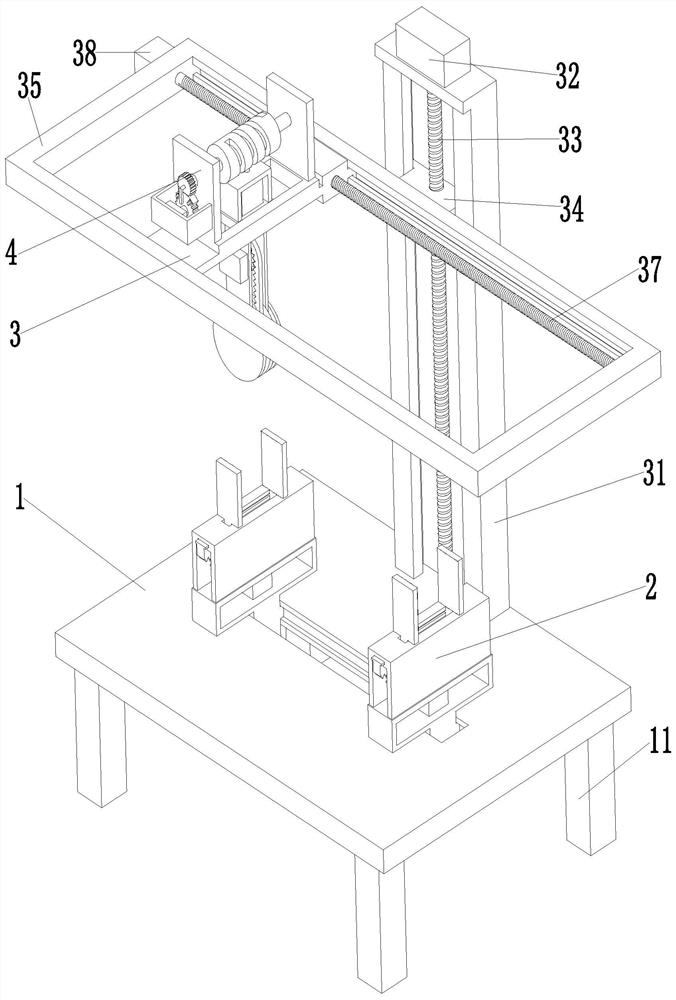

[0031] Such as Figure 1 to Figure 8 As shown, a wooden slide surface grinding treatment equipment includes a base plate 1, a clamping device 2, a moving device 3 and a polishing device 4, the base plate 1 is equipped with a clamping device 2, and the rear end of the base plate 1 is equipped with a moving device 3, which moves A grinding device 4 is installed on the device 3 .

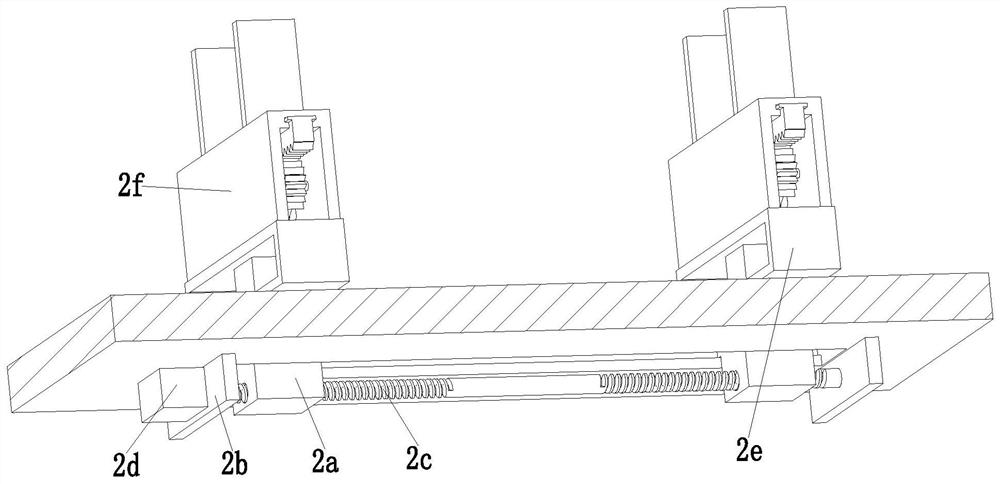

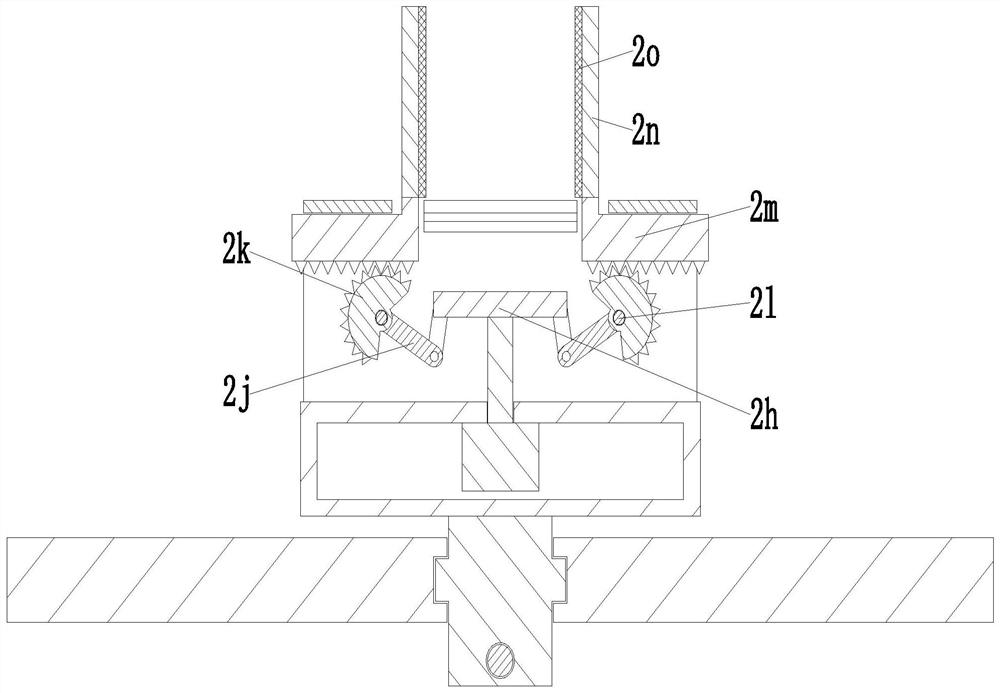

[0032]The clamping device 2 includes a sliding plate 2a, a return plate 2b, a two-way threaded rod 2c, a No. 1 motor 2d, a rectangular frame 2e, a U-shaped plate 2f, a telescopic cylinder 2g, a flat rod 2h, a square rod 2i, and a connecting rod 2j, half gear 2k, positioning round rod 2l, rack 2m, clamping plate 2n and rubber plate 2o, a chute is opened in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com