High-precision adjustable positioning device and method for processing and testing shaft parts

A technology of shaft parts and positioning devices, which is applied in the direction of measuring devices, optical devices, workpiece clamping devices, etc., can solve the problems of adjustment and precise positioning without high precision, and achieve low cost, convenient adjustment, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

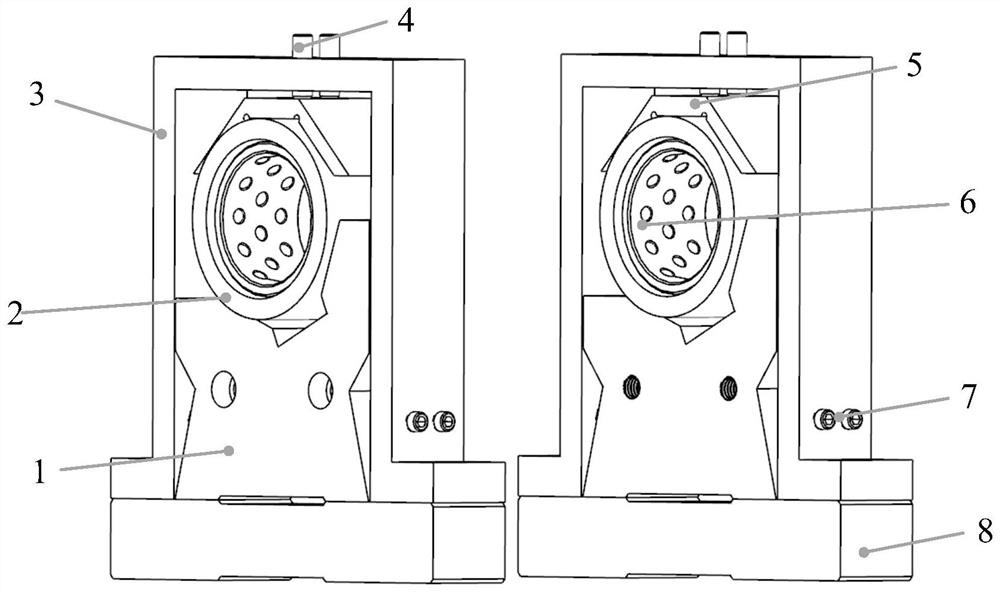

[0023] The method for assembling and using a high-precision adjustable positioning device for processing and testing shaft parts includes the following steps:

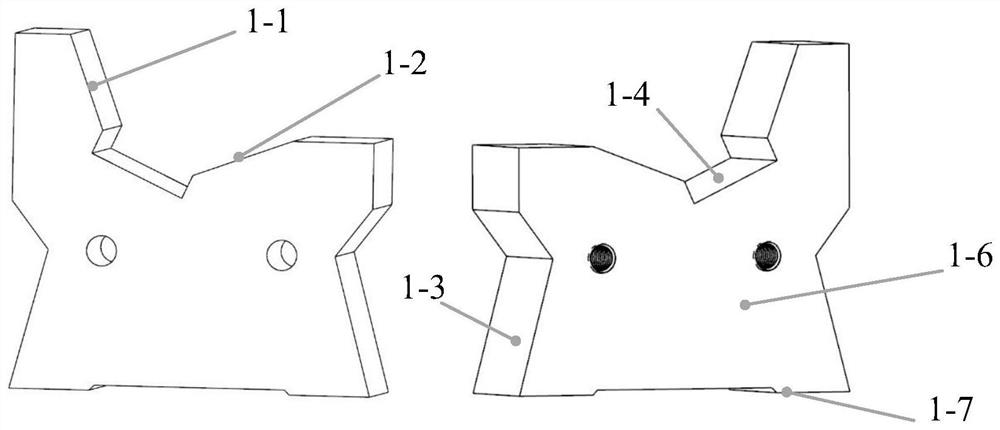

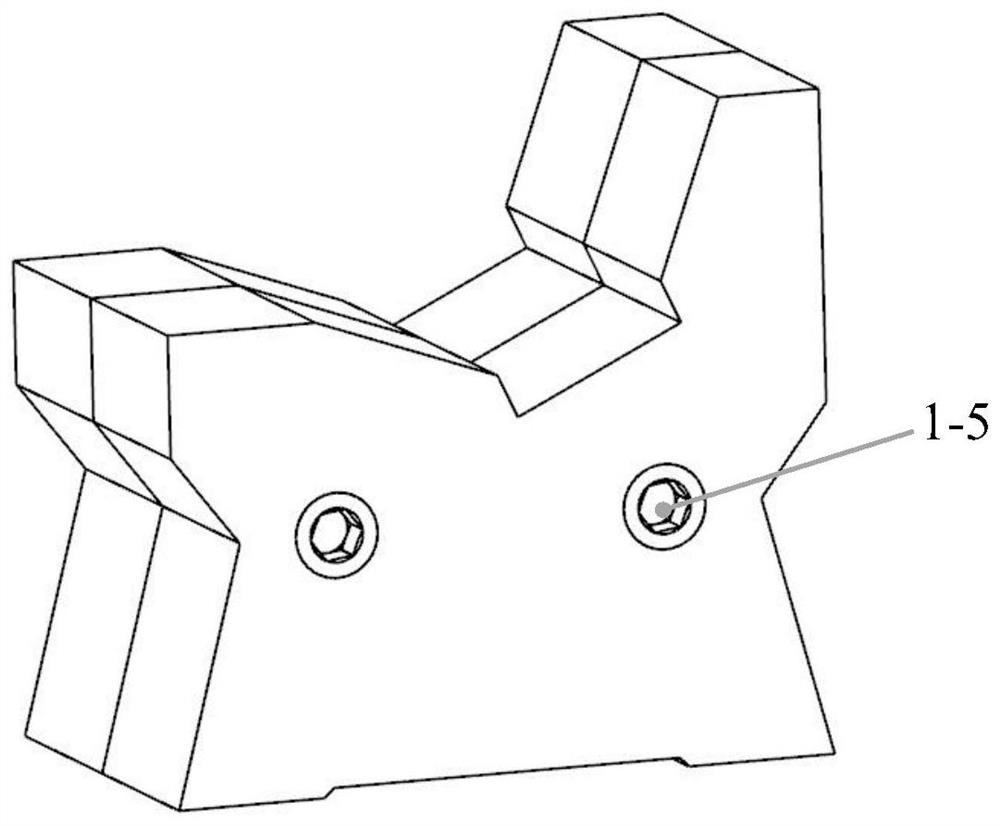

[0024] 1) Before assembly, use the high-precision grinding plate that has been ground to refine the knife-edge ruler, which will more than double the accuracy of the knife-edge ruler; use the above-mentioned high-precision grinding plate to fine-tune the connecting surfaces 1-6 of the asymmetric V-shaped block 1 , the positioning surface 1-7, the upper and lower sides of the cushion block 8 and the bottom surface of the fixed frame 3 are refined;

[0025] 2) The two asymmetric V-shaped blocks 1 are processed synchronously with GCr15 material. The two working surfaces are perpendicular to each other, and the angles with the horizontal plane are respectively 70° and 20°, and the adjustment surfaces 1-3 are at 75° with the horizontal plane. In order to ensure its dimensional consistency, the two asymmetric V-shaped blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com