Efficient tightening device for quick coupling assembly

An efficient and fast technology, applied in hand-held tools and manufacturing tools, etc., can solve problems such as low assembly efficiency, loose clamping of three-jaw chucks, and cumbersome operations, so as to improve the qualified rate of tightening, prevent thread seizure, and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

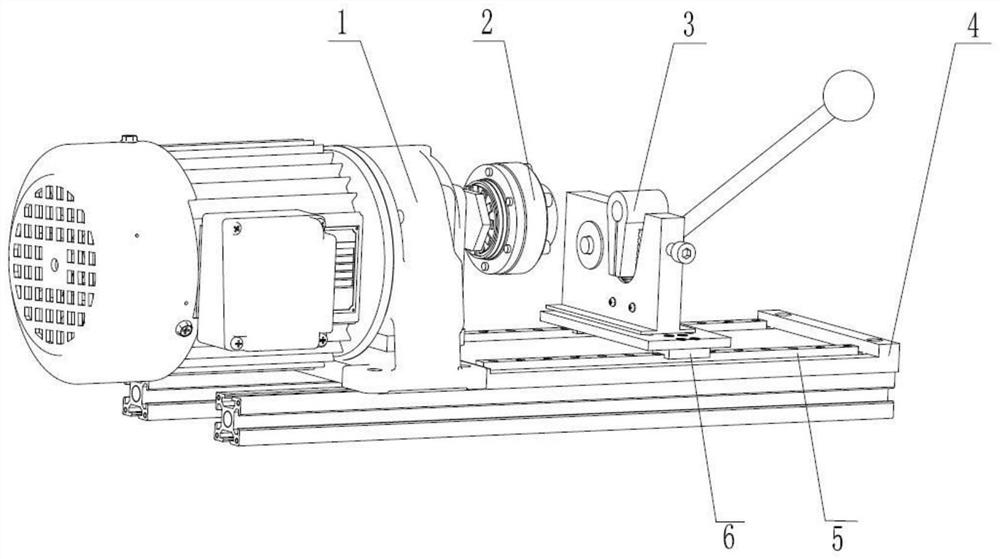

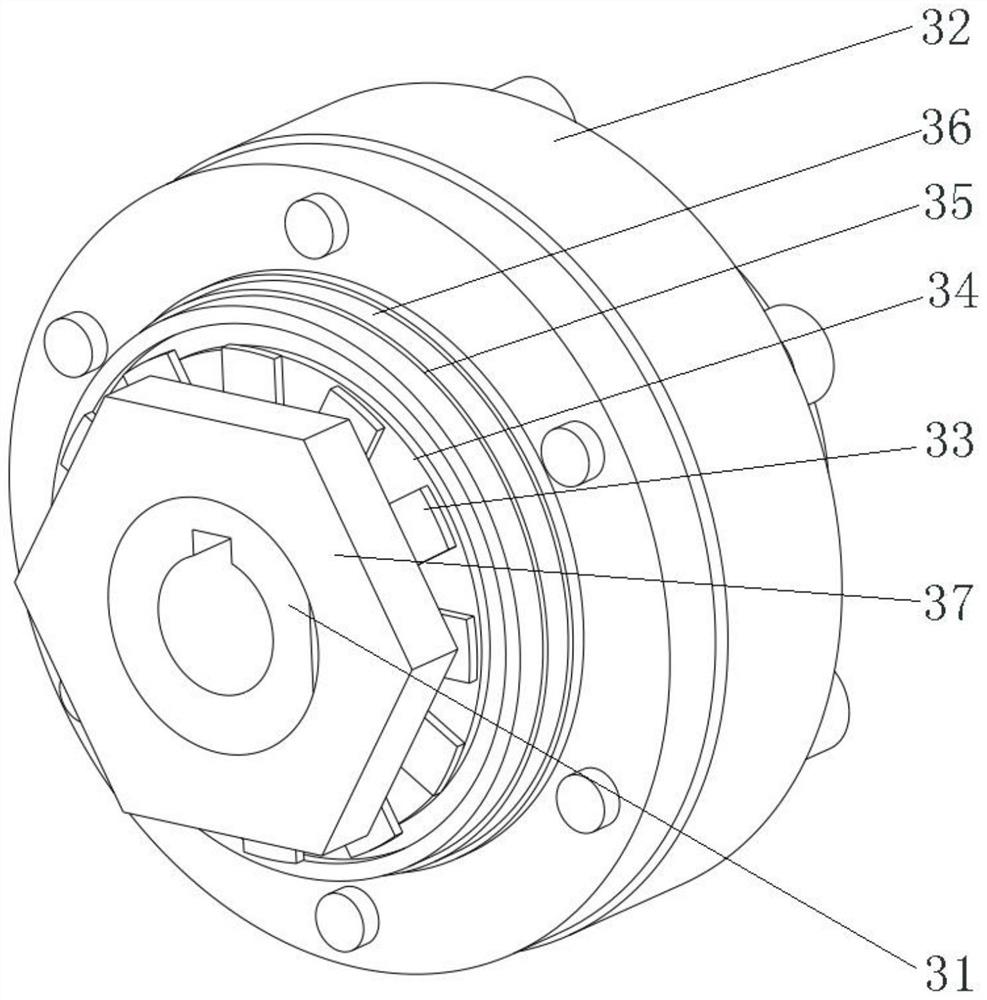

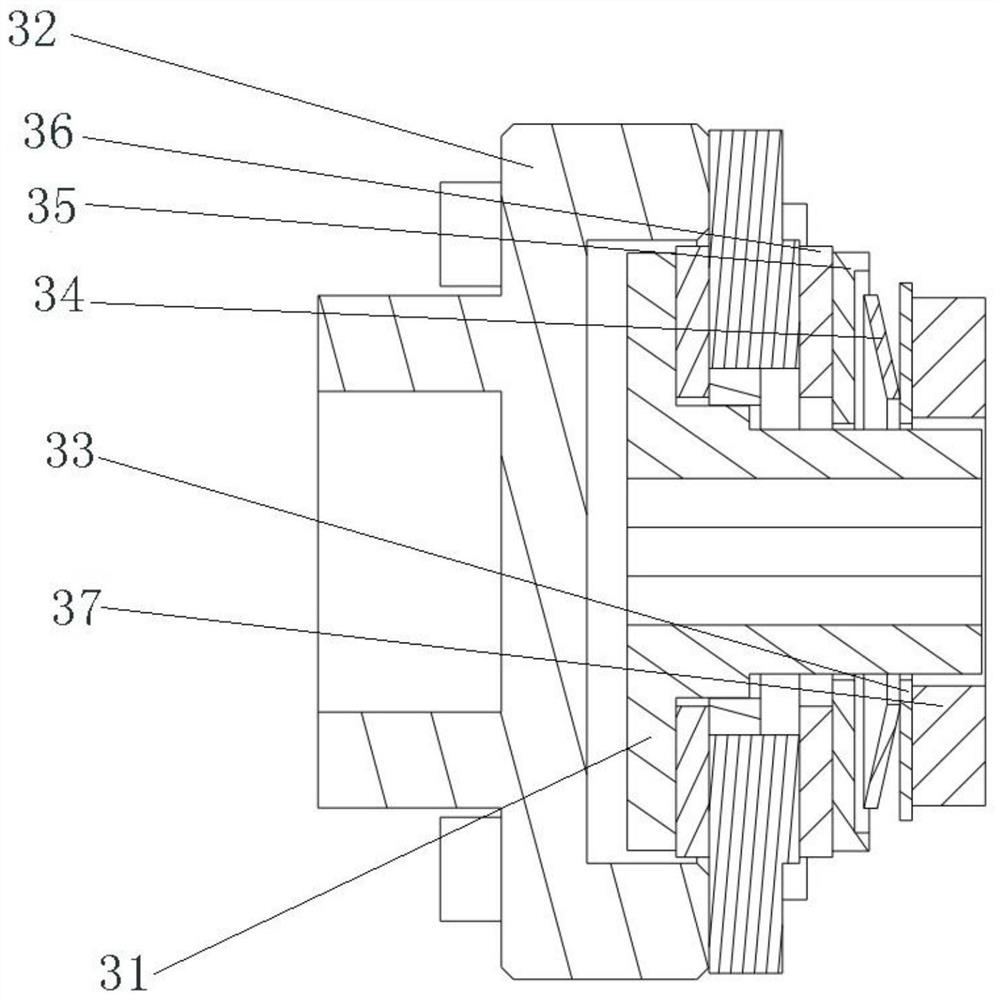

[0022] Such as figure 1 As shown, 1) Preparation before tightening: adjust the adjusting nut 37 of the torque limiter 3 to set the maximum output value of the torque limiter 3; adjust the adjusting nut 46 of the clamping device 4: ensure that the clamping sleeve is in the clamped state The hole center of 47 is coaxial with the torque limiter output port hole;

[0023] 2) After screwing the part seat shell into the 1-3 screw buckles of the seat external shell, the seat shell is clamped by the clamping sleeve 47, and the seat external shell is inserted into the output end 32 of the torque limiter;

[0024] 3) Start the motor;

[0025] 4) The torque limiter 3 drives the seat outer shell to rotate, so that the seat shell is screwed into the seat outer shell;

[0026] 5) After the thread is screwed to the set torque, the output end 32 of the torque limiter stops rotating;

[0027] 6) When the clamping device 4 is clamping the housing of the seat, the external housing of the seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com