Oil-water separator for sewage treatment

A technology of oil-water separator and sewage treatment, which is applied in liquid separation, separation method, grease/oily substance/floating matter removal device, etc. It can solve the problems of affecting the separation efficiency of sewage, the number of honeycomb holes, and the inconvenience of compartment cleaning. Achieve the effects of wide application range, avoid oil conjunctiva, improve cleaning efficiency and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

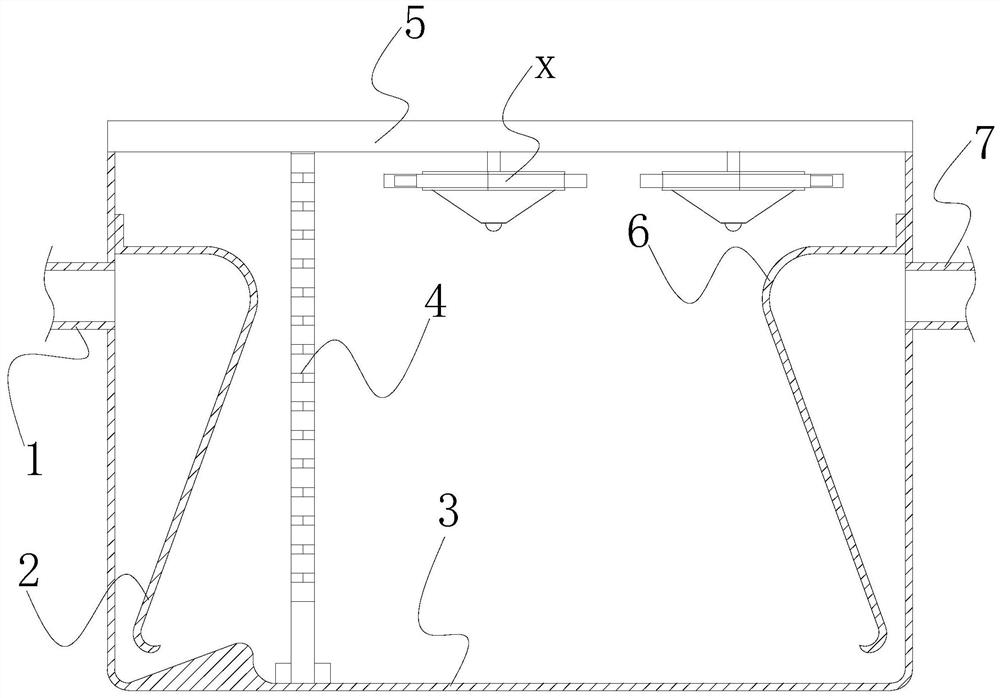

[0026] see Figure 1-6 , the present invention provides a technical solution of an oil-water separator for sewage treatment: its structure includes a sewage inlet pipe 1, a first guide plate 2, a body 3, a partition 4, a top cover 5, a second guide plate 6, an outlet Water pipe 7, the top of the body 3 is connected with a top cover 5, one end of the body 3 is connected to the sewage inlet pipe 1, and the other end is connected to the water outlet pipe 7, and the interior of the body 3 is provided with a partition 4, so A first guide plate 2 is provided between the interlayer 4 and the sewage inlet pipe 1, the first guide plate 2 is connected to the body 3, and a second guide plate 6 is provided between the interlayer 4 and the outlet pipe 7 , the second guide plate 6 is in contact with the body 3, the first guide plate 2, the second guide plate 6 have a gap with the inner bottom surface of the body 3, and the gap is used for the circulation of water.

[0027] The interlayer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com