Electromechanical automatic glass etching and coating device

A glass and etching technology, which is applied in the field of electromechanical automatic glass etching coating devices, can solve the problems of easy scratching of painted patterns, uneven application of paraffin wax, waste of paraffin wax, etc., and achieves the effect of solving uneven application of paraffin wax.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

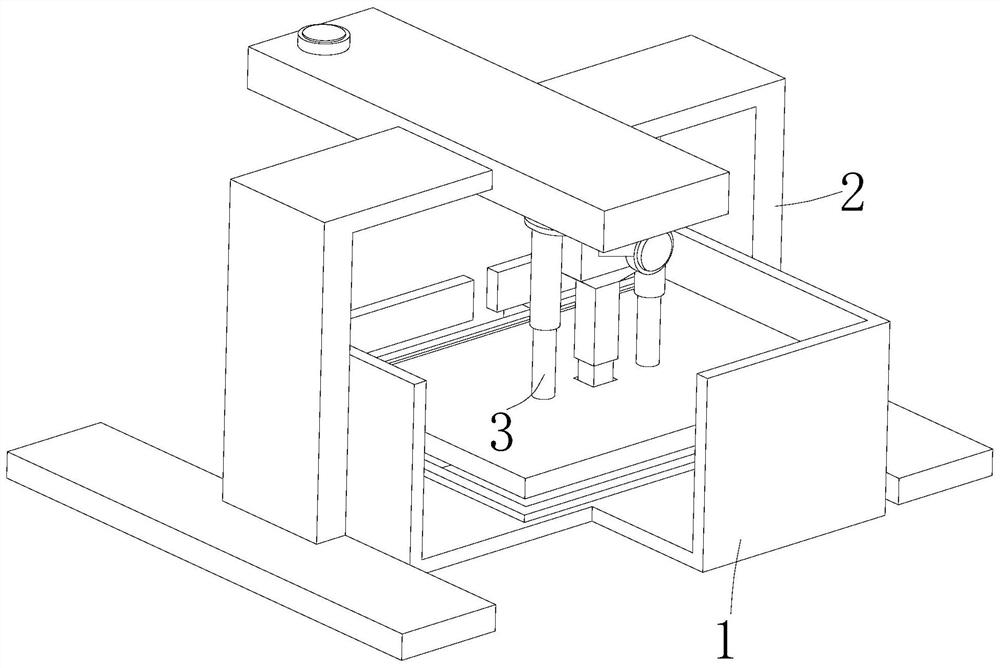

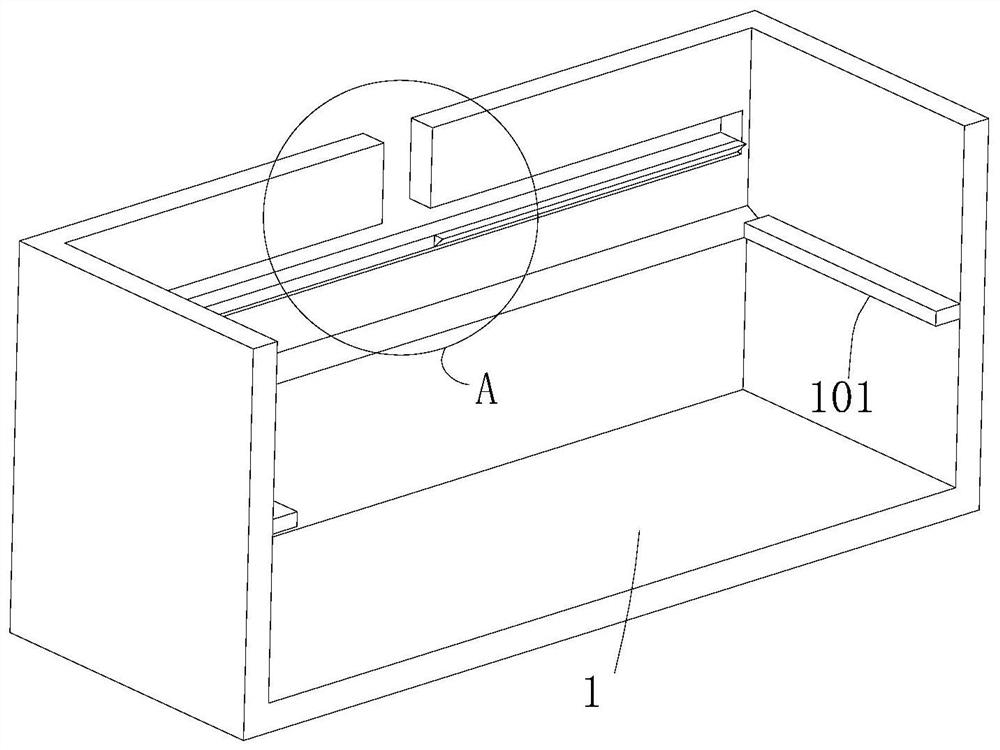

[0025] Embodiment one, such as Figure 1-7 As shown, a melting pool 1 is included, a supporting mechanism 2 is arranged above the melting pool 1, and a fixing mechanism 3 is slidingly connected to the inside of the supporting mechanism 2, and a support plate 101 is fixedly installed in the middle of the inner side wall of the melting pool 1, and a Heated paraffin, the support plate 101 is flush with the paraffin solution.

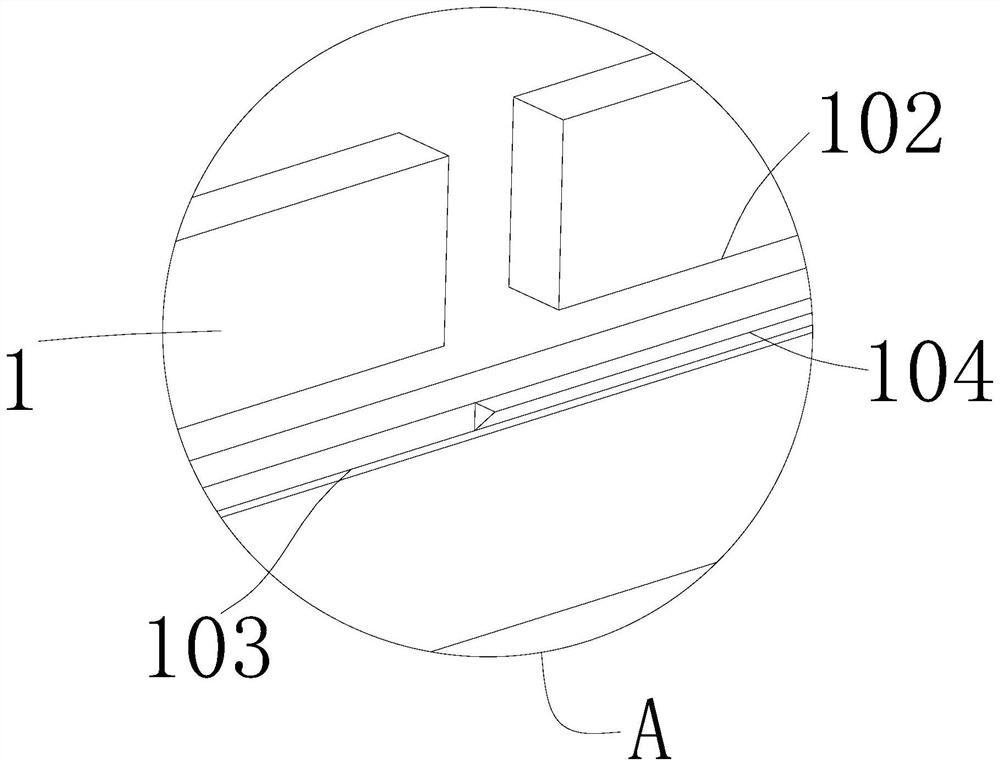

[0026] The rear side wall of the melting pool 1 is located above the support plate 101 and is provided with a through groove 102. The support plate 101 is divided into four pieces, and the support plate 101 positioned at the side of the through groove 102 is chamfered. The removed paraffin automatically falls into the melting tank 1 for melting so as to avoid the waste of paraffin.

[0027] The inner side wall of the melting pool 1 is located below the through groove 102 and is provided with a half through groove 103. The inside of the half through groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com