Alloy material for manufacturing polyethylene pipeline for water supply and preparation method

An alloy material and polyethylene technology, which is applied in the field of alloy material and preparation of polyethylene pipes for water supply, to avoid performance degradation and quality reduction, and achieve the effects of high efficiency, safety and antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

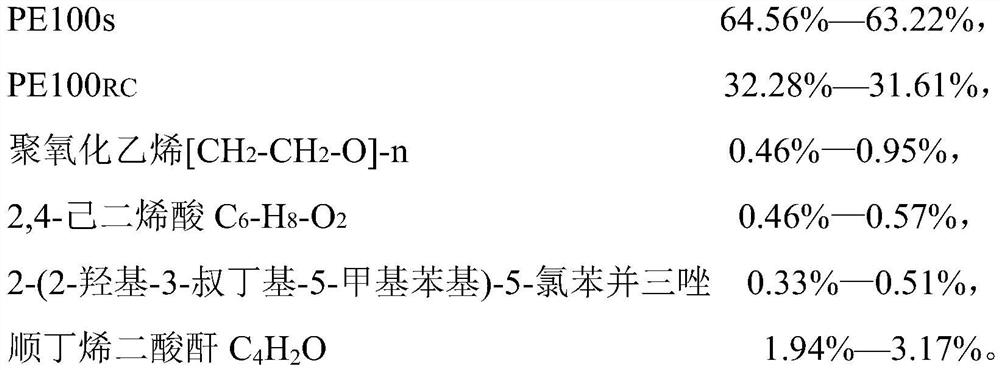

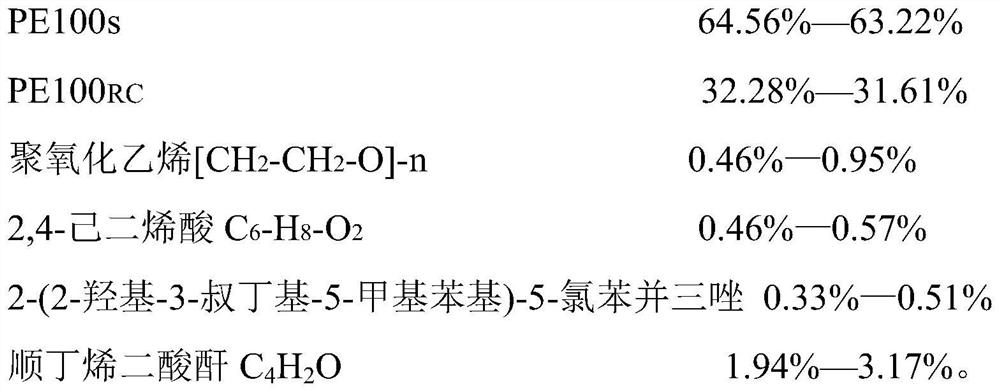

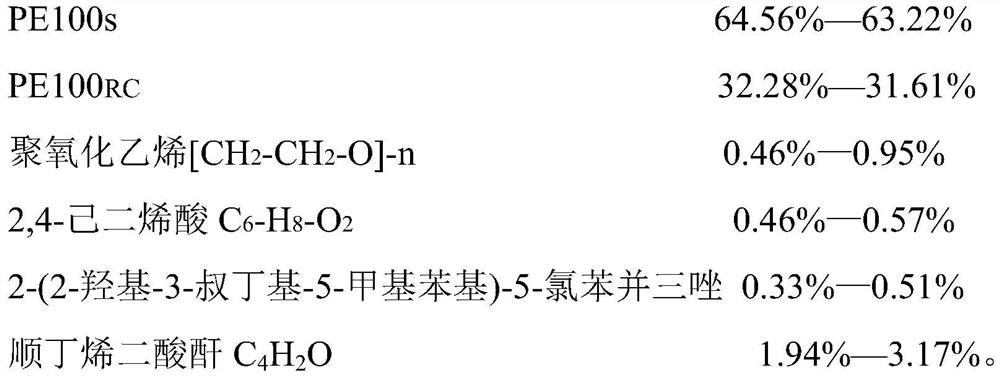

[0016] Embodiments of the present invention will now be described in detail. An alloy material for polyethylene pipes for water supply, the material components of which are as follows in terms of percentages:

[0017]

[0018] The preparation process of the present invention is as follows:

[0019] 1. According to the proportion and serial number of the raw material components, put them in the container of the high-speed mixer in sequence, then turn on the power switch and stir for 5-10 minutes, and the motor speed is ≥ 750 rpm. After the materials are evenly mixed, turn off the power switch and draw out Material baffle, so that the mixture slowly flows into the barrel for use in the next process.

[0020] Raw material formula→high temperature mixing→(60—70℃ / 10min)→cooling and dispersing→(10—20℃ / 10min)→store in barrel.

[0021] 2. Inhale the mixture in the barrel into the barrel of the extruder, then turn on the power switch and slowly turn the control knob of the reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com