Washing machine

A washing machine and inner drum technology, applied in the field of washing machines, can solve problems such as easy accumulation of dirt, inability to clean, increased bacteria in washing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

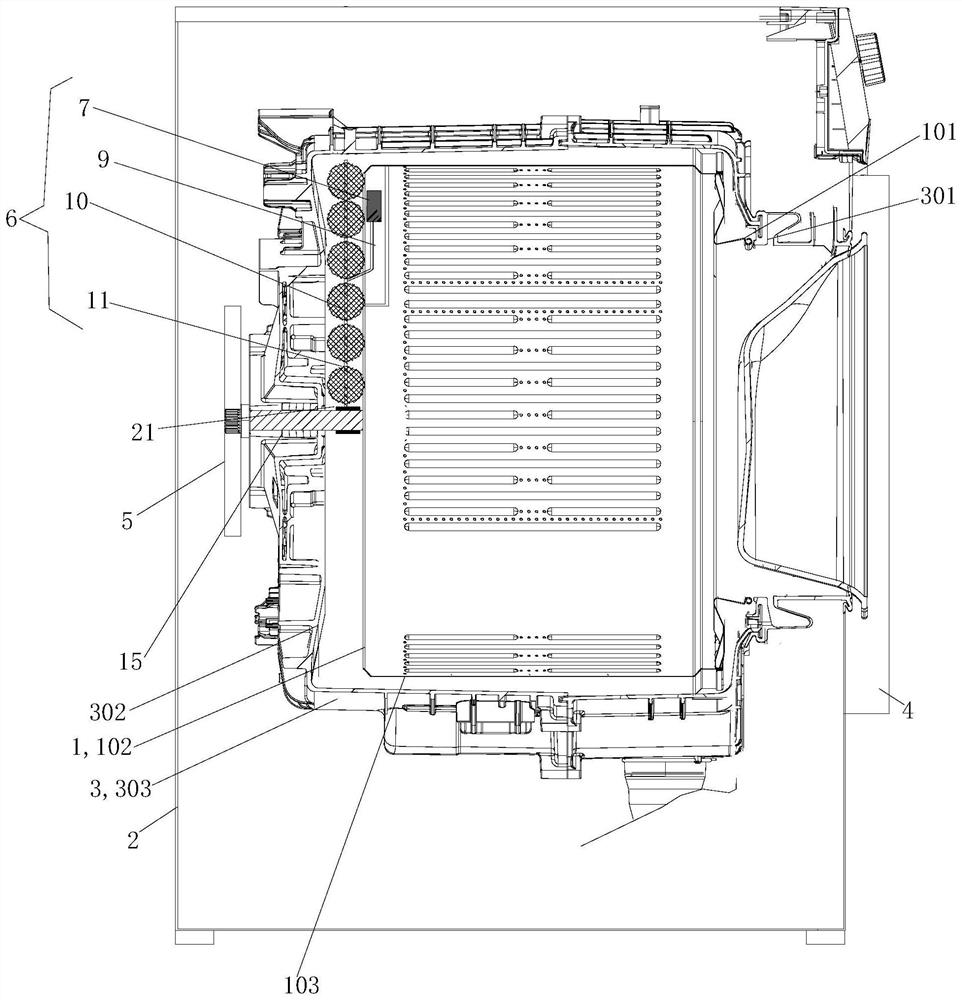

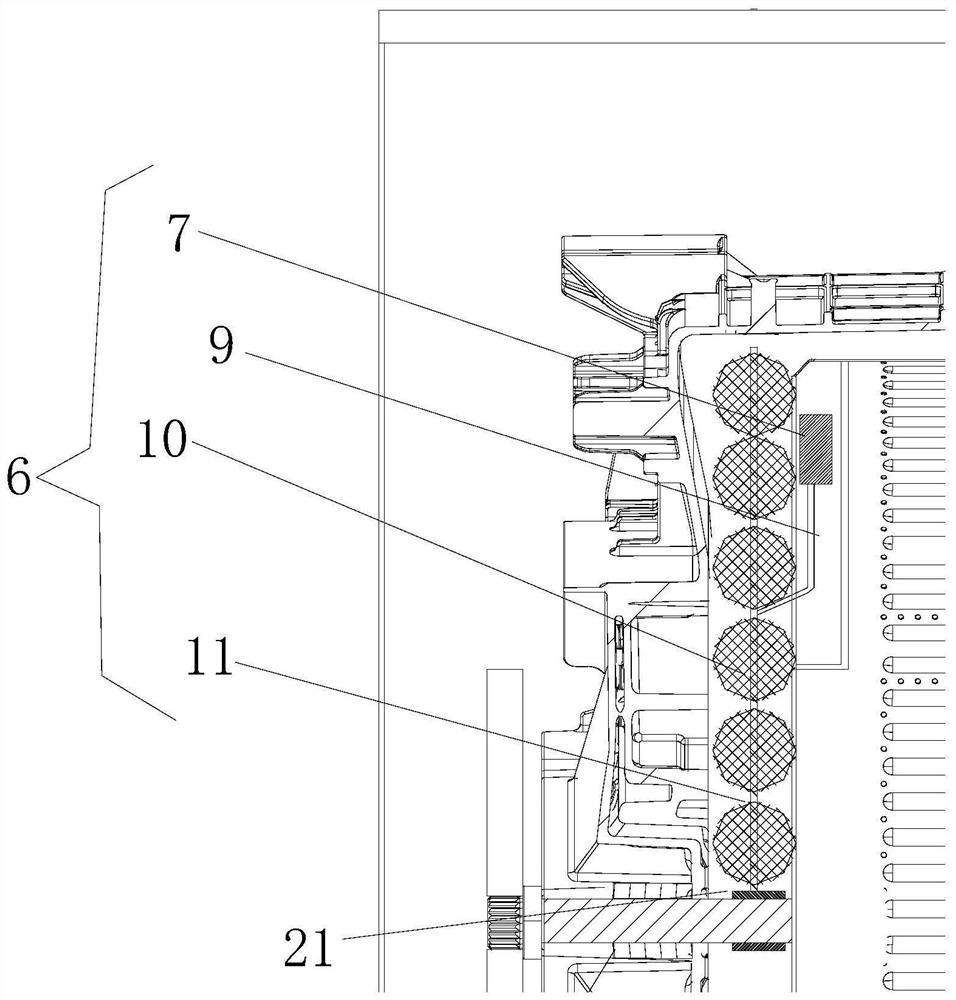

[0044] Such as figure 1 and image 3 As shown, a washing machine is introduced in this embodiment. The washing machine includes an outer cylinder 3, and an inner cylinder 1 is set inside the outer cylinder 3. The driving motors 5 are connected so that the driving motor 5 drives the inner cylinder 1 to rotate through the inner cylinder shaft 21 . There is a certain gap between the inner cylinder bottom 102 and the outer cylinder bottom 302 to ensure that the inner cylinder 1 will not be blocked by the friction of the outer cylinder during the rotation process. At least one centrifugal brush 6 is provided in the gap between the inner cylinder bottom 102 and the outer cylinder bottom 302 to clean the outside of the inner cylinder bottom 102 and the inside of the outer cylinder bottom 302 . At the same time, during the high rotation process of the inner cylinder 1, the centrifugal brush 6 is tightly attached to the inner cylinder bottom 102 by the centrifugal force of the inner ...

Embodiment 2

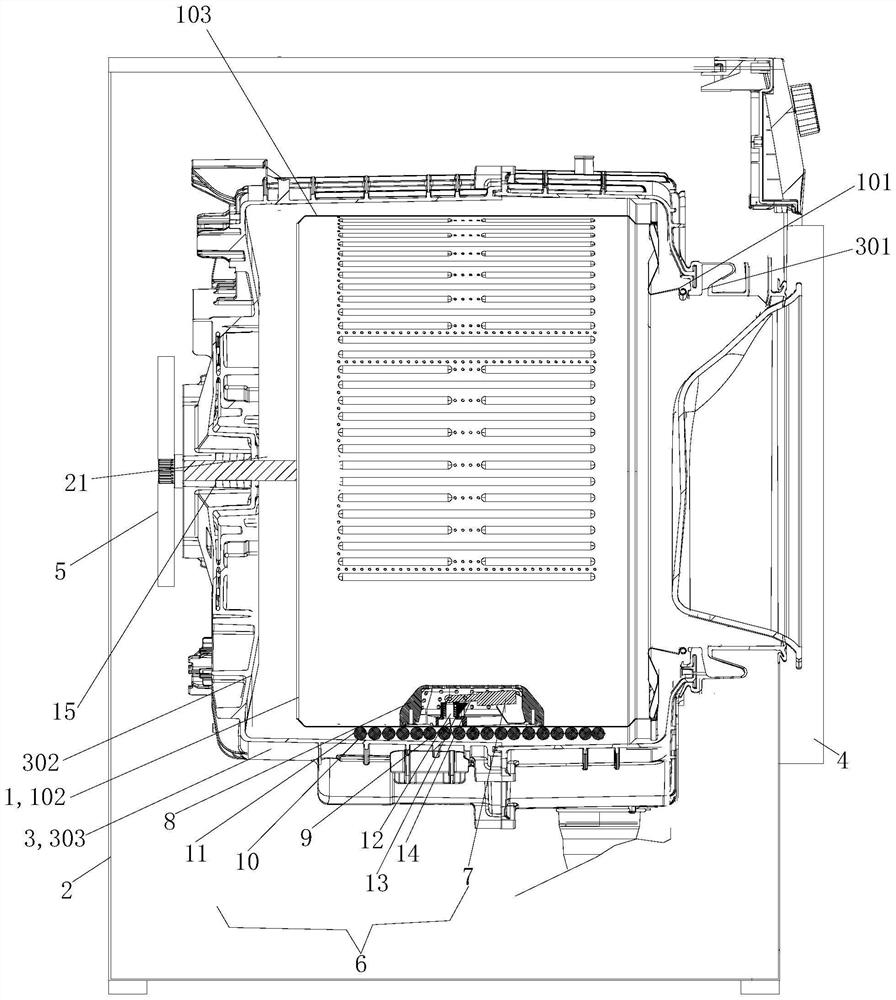

[0056] Such as figure 2 and Figure 4 As shown, a washing machine is introduced in this embodiment. The washing machine includes an outer cylinder 3, and an inner cylinder 1 is set inside the outer cylinder 3. The driving motors 5 are connected so that the driving motor 5 drives the inner cylinder 1 to rotate through the inner cylinder shaft 21 . The inner cylinder 1 and the outer cylinder 3 have cylindrical inner cylinder sidewalls 103 and outer cylinder sidewalls 303 respectively, and there is a certain gap between the inner cylinder sidewalls 103 and the outer cylinder sidewalls 303 to ensure that the inner cylinder 1 rotates Can not be blocked by outer tube 3 friction. At least one centrifugal brush 6 is provided in the gap between the inner cylinder sidewall 103 and the outer cylinder sidewall 303 to clean the outside of the inner cylinder sidewall 103 and the inside of the outer cylinder sidewall 303 . At the same time, during the high rotation process of the inner c...

Embodiment 3

[0068] This embodiment is based on the first and second above-mentioned embodiments, and also has the following distinguishing technical features: the inner cylinder 1 of the washing machine is not provided with a normally open through hole, so that the inner cylinder 1 forms a sealed water container when the washing machine is in the washing state, so that the washing water only The flow inside the inner cylinder 1 makes the washing machine form a non-porous inner cylinder washing machine, so that the phenomenon of cross flow of washing water between the inner and outer cylinders is completely eliminated when the washing machine is washing.

[0069] In addition, the washing machine in this embodiment can be any washing machine in the prior art with the inner drum 1 forming a sealed container after the door cover closes the inner drum mouth 101, so as to control the inner drum 1 to rotate at a high speed when the washing machine executes the dehydration program. The water flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com