Quickly-assembled double-layer corrugated steel square culvert structure and construction method

A technology of corrugated steel and square culverts, applied in the field of box culvert construction, can solve the problems of increased workload and inability to realize rapid assembly, and achieve the effect of reducing workload, shortening assembly time, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

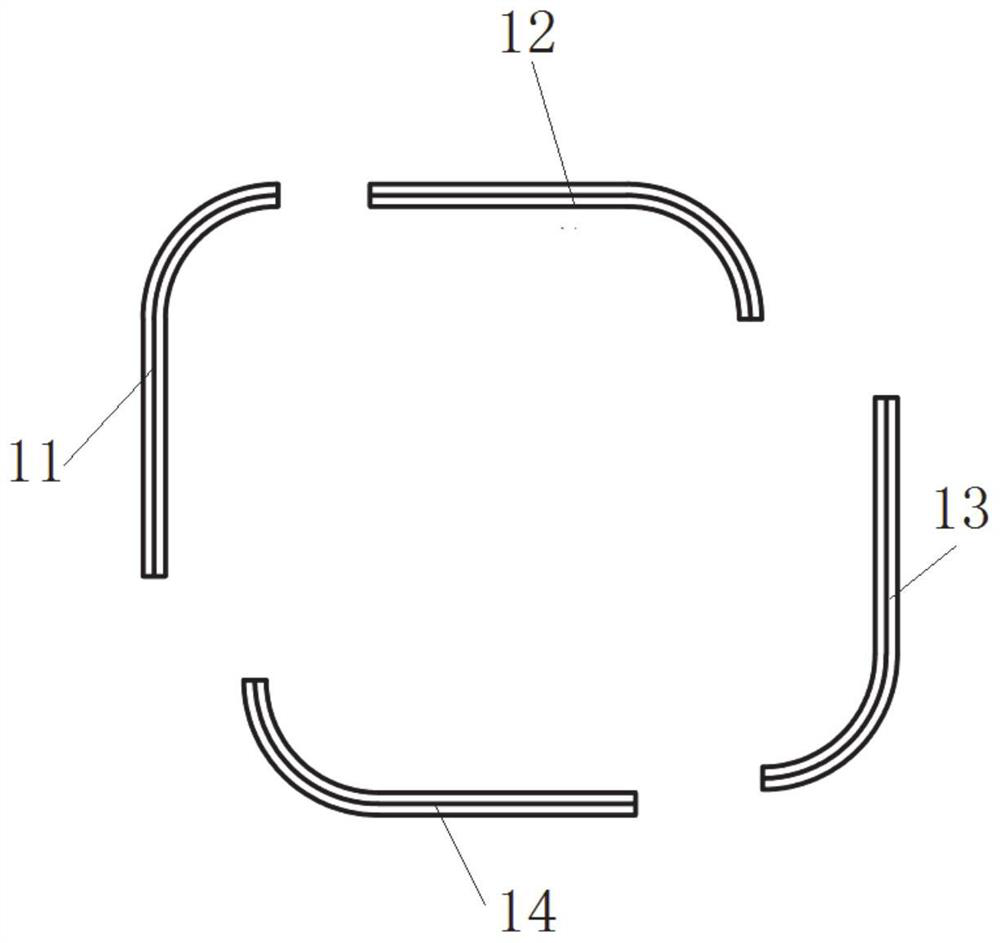

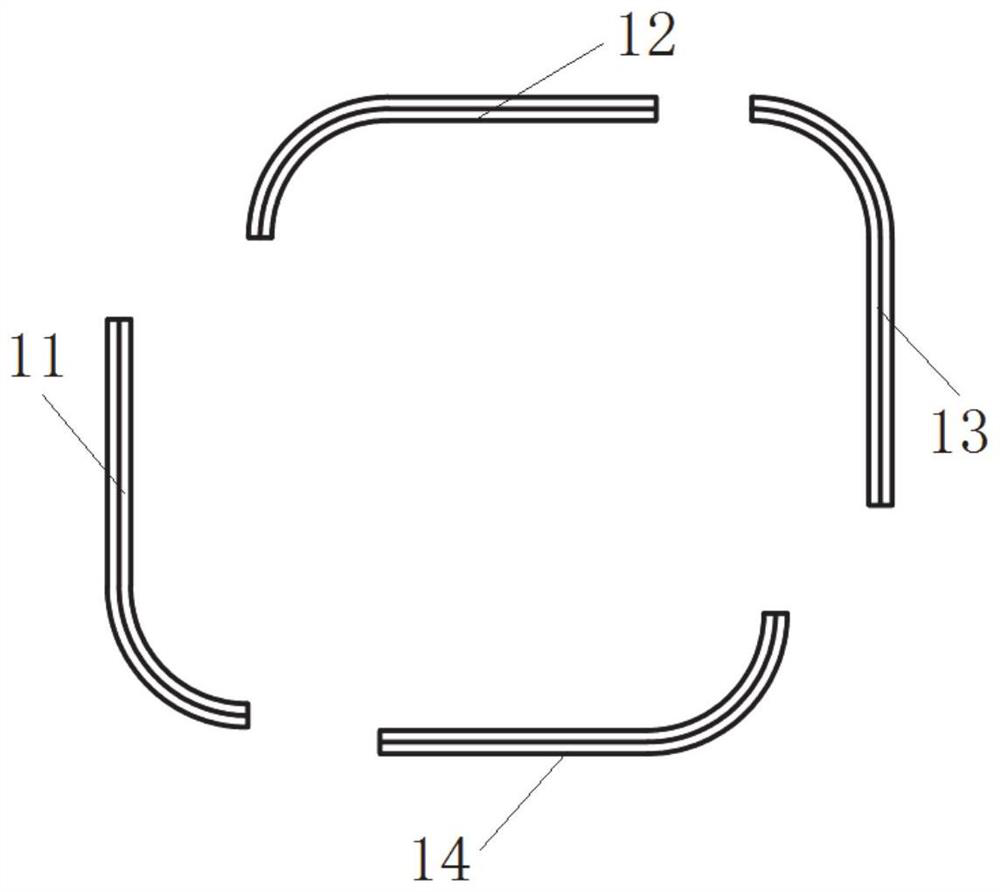

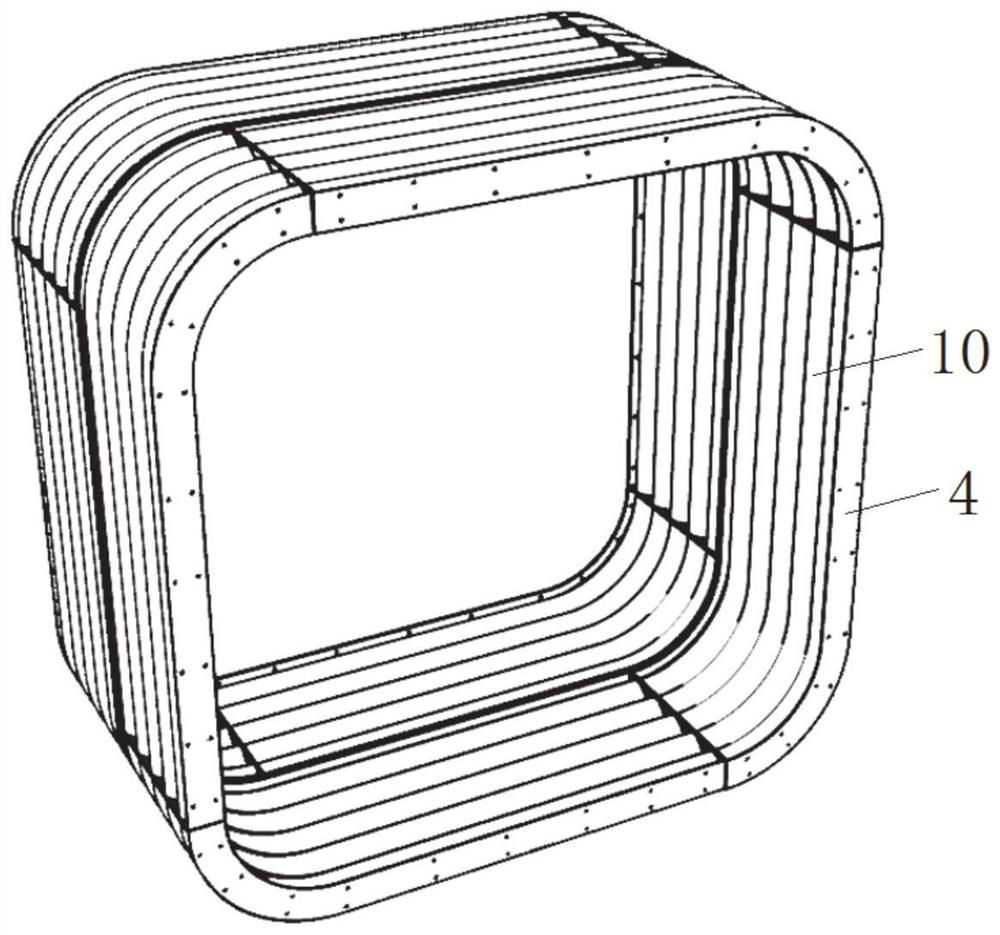

[0031] In a typical embodiment of the present invention, such as Figure 4 and Figure 5 As shown, a splicing body for forming a square culvert is proposed. The splicing body is continuously arranged along a set direction when forming a square culvert, and includes a plurality of plates 10, and the plurality of plates 10 are sequentially connected end to end to form a closed ring structure; each The structure and shape of each panel 10 are the same, but the positions in the splicing body are different. There are four panels 10 in this embodiment, which are named according to their positions in the splicing body, which are the first side panels in turn. Parts, top panels, second side panels and bottom panels; each panel 10 includes an inner corrugated board 1 and an outer corrugated board 2, and in this embodiment, an inner corrugated board 1 and an outer corrugated board 2 It is also named according to its position in the splicing body. The side directly in contact with the e...

Embodiment 2

[0043] In a typical embodiment of the present invention, such as Figure 2-Figure 5 As shown, a fast-assembled double-layer corrugated steel square culvert structure is proposed, which can realize rapid splicing, including multiple splicing bodies. The splicing body in this embodiment adopts the splicing body described in Example 1, and the splicing body is The direction perpendicular to the extension of the crest of the corrugated plate is sequentially connected to form a square culvert. The adjacent splicing bodies are connected by a ring flange 4, and a gasket is provided between the adjacent ring flanges 4 to ensure the connection. Has good sealing.

[0044] In yet another embodiment, such as figure 1 and figure 2 As shown, the splicing body includes two configurations, and the two configurations are respectively named as the first splicing body and the second splicing body, such as image 3 For plain food, the first splicing body and the second splicing body are arran...

Embodiment 3

[0054] In yet another typical implementation of the present invention, a construction method of a double-layer corrugated steel closed square culvert structure is proposed, which uses the square culvert structure as described in Example 2, comprising the following steps:

[0055] In the radial direction, the adjacent plates are connected through the end flange 3;

[0056] In the axial direction of the channel of the required closed square culvert structure, it is connected through the circumferential flange 4 of the splicing body;

[0057] If two kinds of splicing bodies are used, the first splicing bodies and the second splicing bodies are arranged alternately along the circumferential direction of the channel of the closed square culvert structure, so that the second splicing bodies are arranged between the first splicing bodies that are separated, or the second splicing bodies are arranged between The first splicing body is arranged between the second splicing bodies;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com