Corner pressing device for sanitation brush

A technology of a pressing device and a sanitation brush, which is applied in the field of sanitation brushes, and can solve problems such as retaining springs, unfavorable batch production, troublesome adjustments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

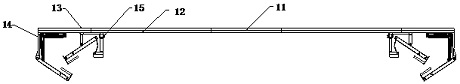

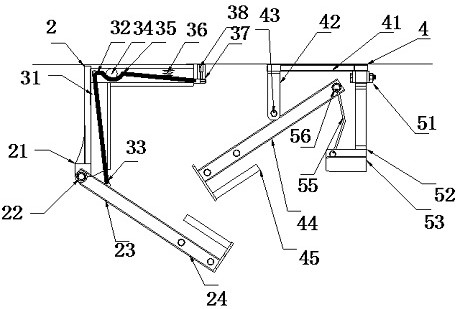

[0024] see figure 1 and figure 2 , an edge and corner pressing device for sanitation brushes, comprising a work frame plate 11, two ends of the work frame plate 11 are provided with a pressing end frame 12, and a side edge frame 13 is provided at the pressing end frame 12 , the inner end positions of the side frame 13 are respectively provided with an external compression frame 14 and a built-in compression frame 15, the main body of the external compression frame 14 is an L-shaped frame 2, and the L-shaped frame 2 A mounting block 21 is installed at the bottom end, and a clamping frame plate 23 is installed on the installation block 21 through the steering shaft 22 . The inner cavity of the profile frame 2 is provided with a transmission cavity 31, the inner cavity of the transmission cavity 31 is provided with a bending support rod 32, and the bending shape of the bending support rod 32 matches the structural shape of the transmission cavity 31, so The upper edge of the t...

Embodiment 2

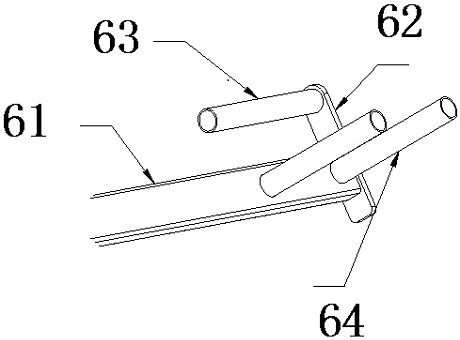

[0028] see image 3 , this embodiment is a further optimization of the first embodiment. On this basis, the first clamping device 24 and the second clamping device 45 are both provided with a mounting substrate 61, and a vertical frame is provided on the mounting substrate 61 Plate 62, the mounting base plate 61 and the vertical frame plate 62 are arranged at right angles, the inner plane of the mounting base plate 61 is provided with a first-level compression column 64, and the vertical frame plate 62 is provided with a second-level compression column 63 , the secondary pressing column 63 is parallel to the mounting substrate 61 and is perpendicular to the primary pressing column 64 . The secondary pressing column 63 is provided with one and is designed near the turning side of the mounting base plate 61 , and the primary pressing column 64 is arranged near the vertical shelf plate 62 . For the docking method of the first clamping device 24 and the second clamping device 45 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com