Scenic area complex terrain steel structure installation method

A technology of complex terrain and installation method, applied in the direction of building structure, construction, building materials processing, etc., can solve the problems that the erection height should not exceed 30 meters, there is no level ground, and vehicles cannot directly access the construction site, etc., to achieve a solution The Effects of Operating Platform Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

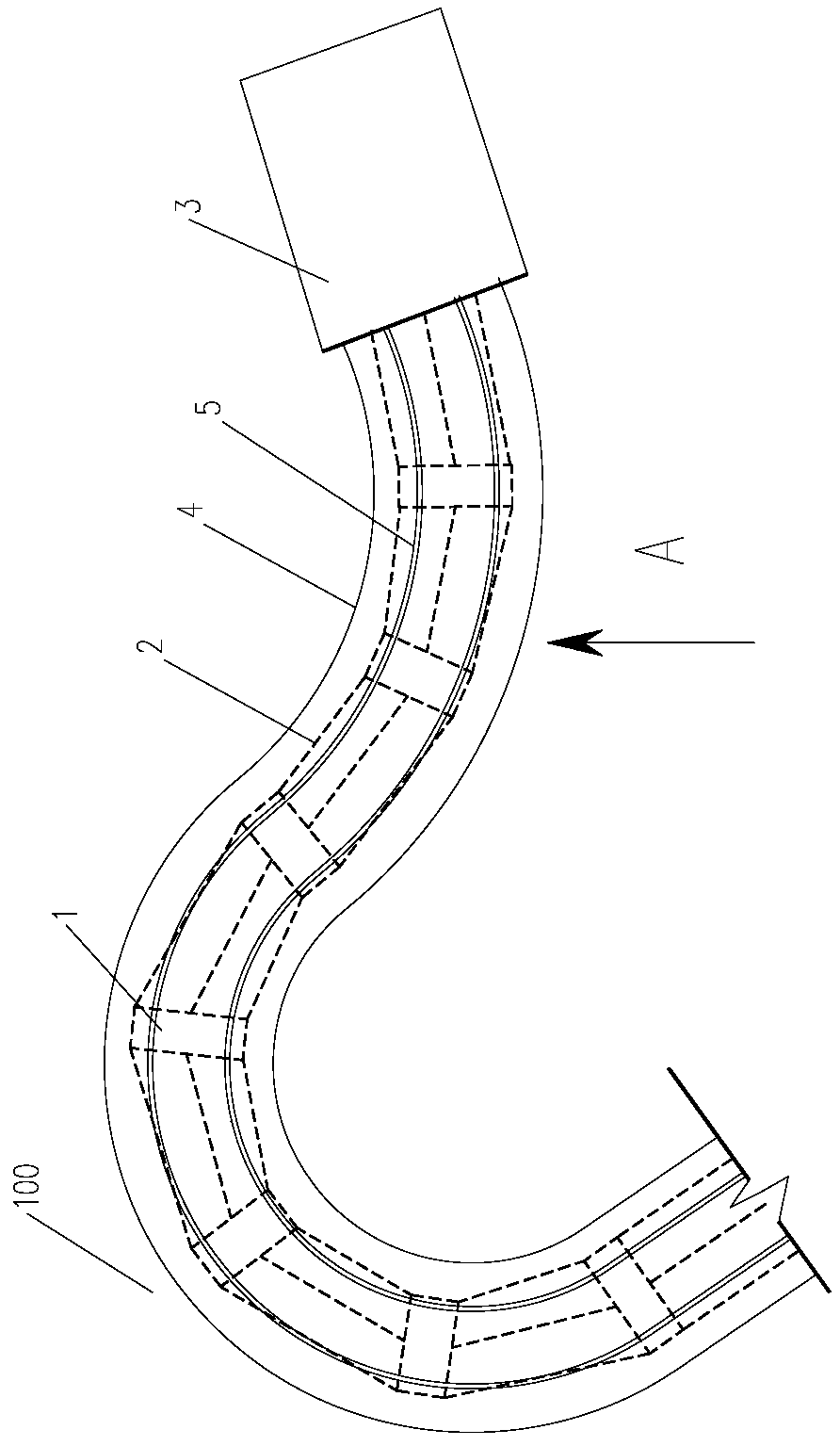

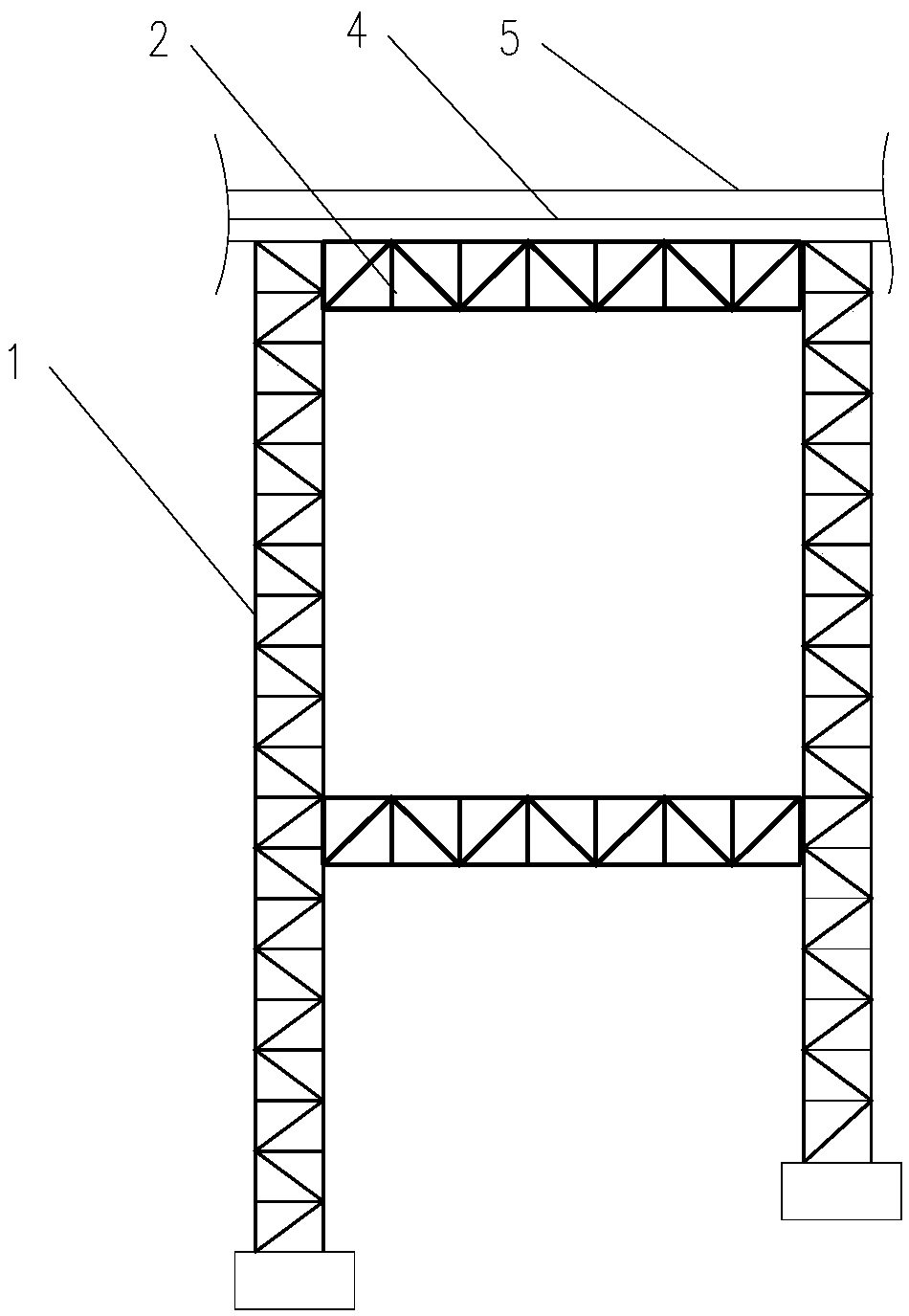

[0020] A method for installing steel structures in complex terrain in scenic spots, such as figure 1 and figure 2 shown, including the following steps:

[0021] A: Decompose the steel structure and supporting frame to be installed into multiple parts, build a cableway between the ground and the unloading platform 3, and transport the multiple parts to the unloading platform 3 through the cableway , the weight of each component is less than the load of the cableway; for example, the steel pipe column in the steel structure is segmented according to the lifting weight of the cableway (1 ton), and the box girder in the steel structure is decomposed into less than 1 ton The steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com