Proppant and method for improving shale reservoir fracturing crack supporting effect

A shale reservoir and proppant technology, which is applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve problems such as the inability to contribute seepage channels, achieve low cost, reduce contact area, and improve effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

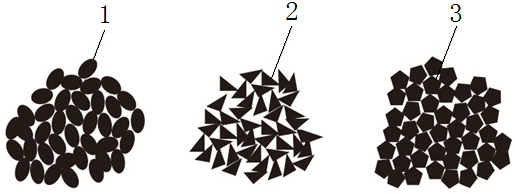

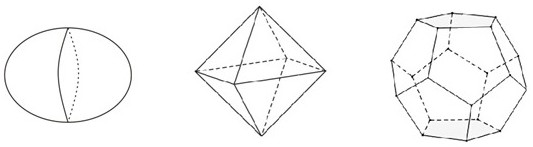

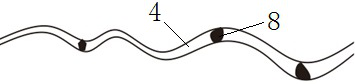

[0036] Embodiment 1, a proppant for improving the propping effect of fracturing fractures in shale reservoirs, made of the following components by weight percentage: 60wt% of waste ceramics, 10wt% of manganese ore powder, 10wt% of red mud and 20 % of bauxite powder. The proppant is a granular material, the particle shape is ellipsoid, regular octahedron and regular dodecahedron, and the mass ratio of ellipsoid particle 1, regular octahedral particle 2 and regular dodecahedral particle 3 is 1: (1~2): (0.5 ~1).

[0037] The waste ceramics is waste from making ceramic utensils, the content of alumina in the waste ceramics is 30-40wt%, and the content of silicon oxide is 20-40wt%.

[0038] The manganese ore powder is made of primary manganese ore, the content of manganese tetraoxide in the manganese ore powder is 5-30wt%, and the content of manganese oxide is 50-80wt%.

[0039] The red mud is the waste after alumina is extracted during aluminum production, and the sum of the con...

Embodiment 2

[0043] Embodiment 2, a proppant for improving the propping effect of fracturing fractures in shale reservoirs, made of the following components by weight percentage: 60wt% of waste ceramics, 15wt% of manganese ore powder, 15wt% of red mud and 10 % of bauxite powder. The preparation process is specifically as follows: firstly, the waste ceramics are ground into granules with a diameter of 0.1-1.5 mm. Grind manganese ore and bauxite into powder respectively. The mass ratio of waste ceramic particles: manganese ore powder: red mud: bauxite is prepared according to the ratio of 6:1.5:1.5:1. Then mix ceramic particles, manganese ore powder, red mud, and bauxite powder in the mixer to form a mixture, so that the uniformity of the mixture is greater than 85% and above.

[0044] Then transfer the homogeneously mixed mixture to a high-temperature combustion kiln, and burn it at a temperature of 1200-1300°C for 5 hours, after fully reacting. Three different shapes of ellipsoid, regul...

Embodiment 3

[0046] Embodiment 3, a method for improving the support effect of fracturing fractures in shale reservoirs, comprising the following steps:

[0047] Step 1, perforating the fracturing target section of the shale reservoir; the shale reservoir is a deep shale gas horizontal well in a certain block, the target layer is the Longmaxi Formation, the well depth is 6400m, and the vertical depth is 4560m. The length of the horizontal section is 1600m, the bottom hole temperature is 145°C, the maximum in-situ stress is 110Mpa, and it is divided into 20 sections with a length of 4850~6400m. During the perforating operation, there are 3 clusters of perforation, each cluster of perforation section is 1.5m long, the hole density is 16 holes / m, the phase angle is 60°, and the total number of holes is 72 holes.

[0048] Step 2. Inject the pre-fluid: pump the pre-fluid with variable displacement, and use 3m one by one 3 / min, 5m 3 / min, 8m 3 / min, 14m 3 / min, 9m 3 / min, 7.5m 3 / min, 13m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com