Main reducer driving and driven gear backlash automatic adjustment detection device

A tooth backlash and automatic adjustment technology, applied in the direction of measuring devices, mechanical backlash measurement, mechanical measuring devices, etc., can solve the problems of poor consistency of adjustment and detection, high labor intensity, and inability to realize automatic operation, so as to reduce labor intensity, Save manpower and improve process consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

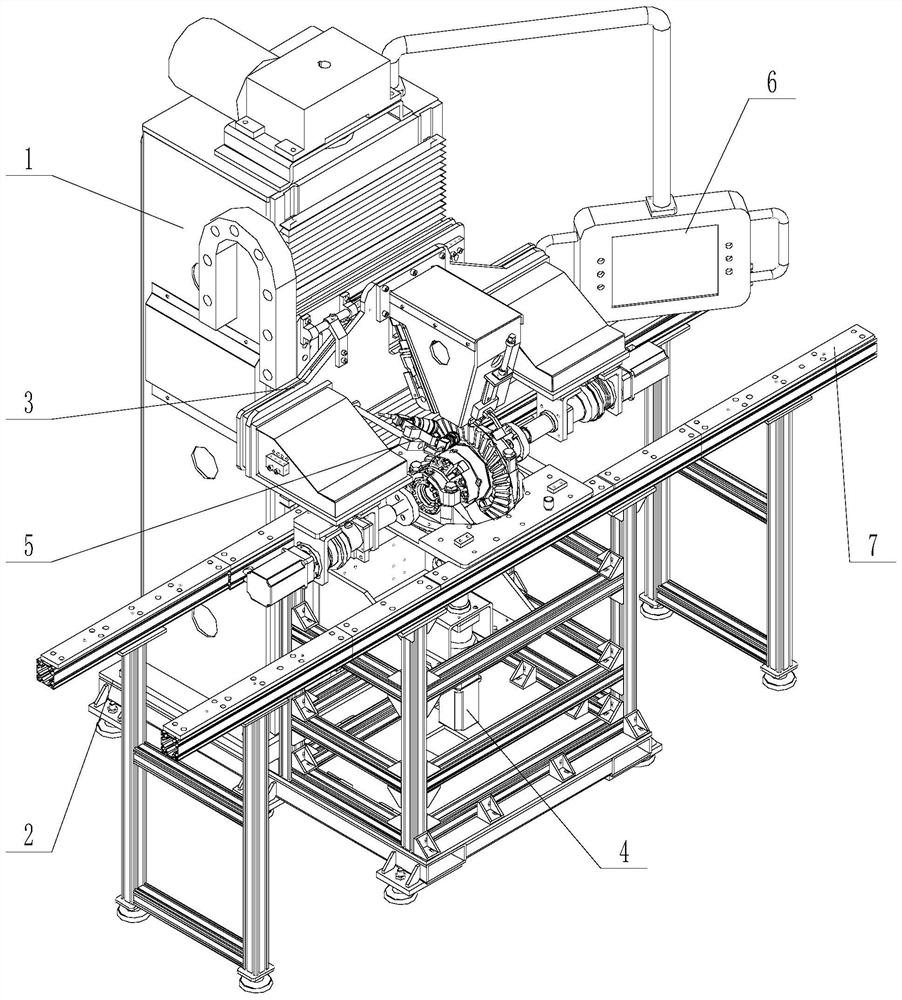

[0030] Such as figure 1 As shown in the figure, an automatic adjustment and detection device for the tooth side clearance of the driving and driven gears of the main reducer, including a lifting body 1, an installation base 2, a tooth side clearance adjustment measurement device 3, a lifting rotation measurement device 4, and a meshing mark photographing analysis system 5 , the operation panel 6 and the conveying line 7, the lifting body 1 is respectively connected with the installation base 2, the tooth side clearance adjustment measurement device 3, the lifting rotation measurement device 4 and the operation panel 6, and the meshing mark photographing analysis system 5 is installed on the tooth side On the gap adjustment measuring device 3 , the installation base 2 is respectively connected with the lifting and rotating measuring device 4 and the conveying line 7 .

Embodiment 2

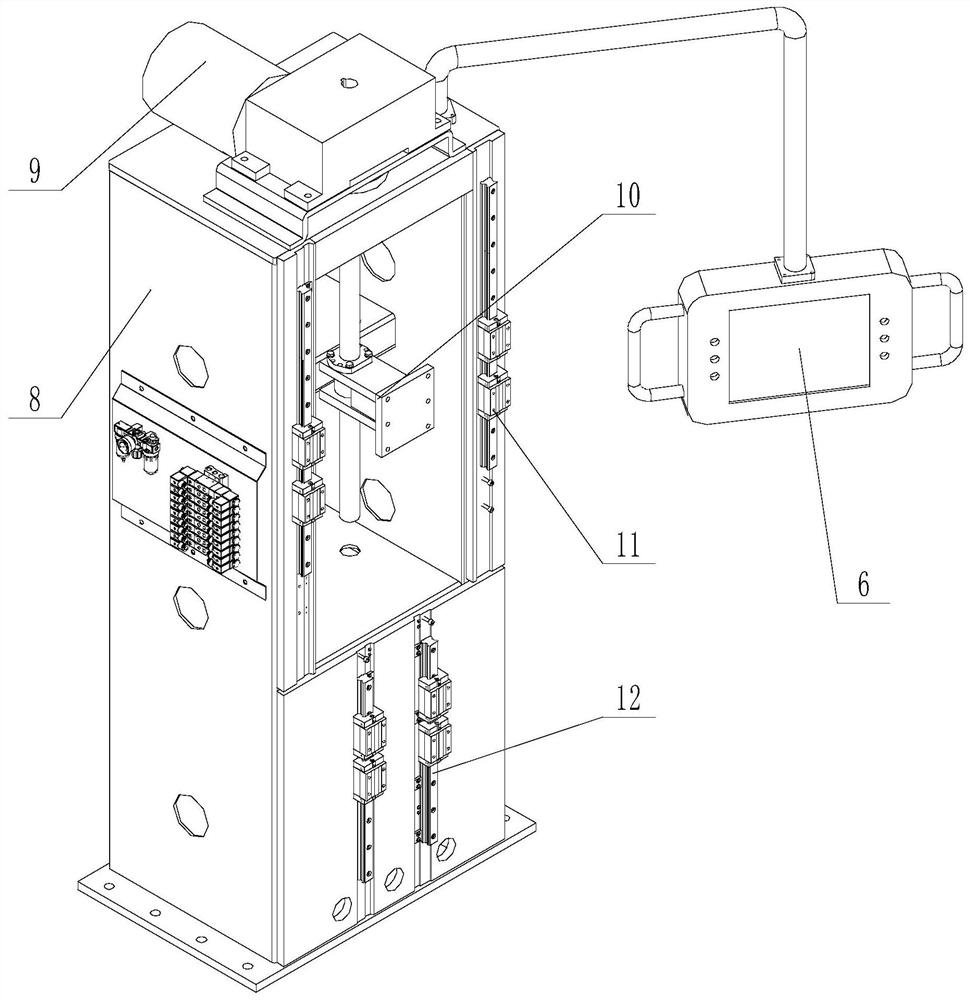

[0032] Such as figure 2 As shown, an automatic adjustment and detection device for the tooth side clearance of the main and driven gears of the main reducer, the lifting body 1 includes a mechanical body 8, a lifting motor 9, a screw module 10, an upper slider module 11 and a lower slider Module 12, the lifting motor 9 is installed on the upper end of the machine body 8, the output end of the lifting motor 9 is connected to the screw module 10, and the upper slider module 11 and the lower slider module 12 are installed on the mechanical One side of body 8. The operation panel 6 is connected to the mechanical body 8 . The upper slider module 11 and the lower slider module 12 both have a slider+guide rail structure, the guide rail is installed on the mechanical body 8, and the slider can slide up and down and be installed on the guide rail.

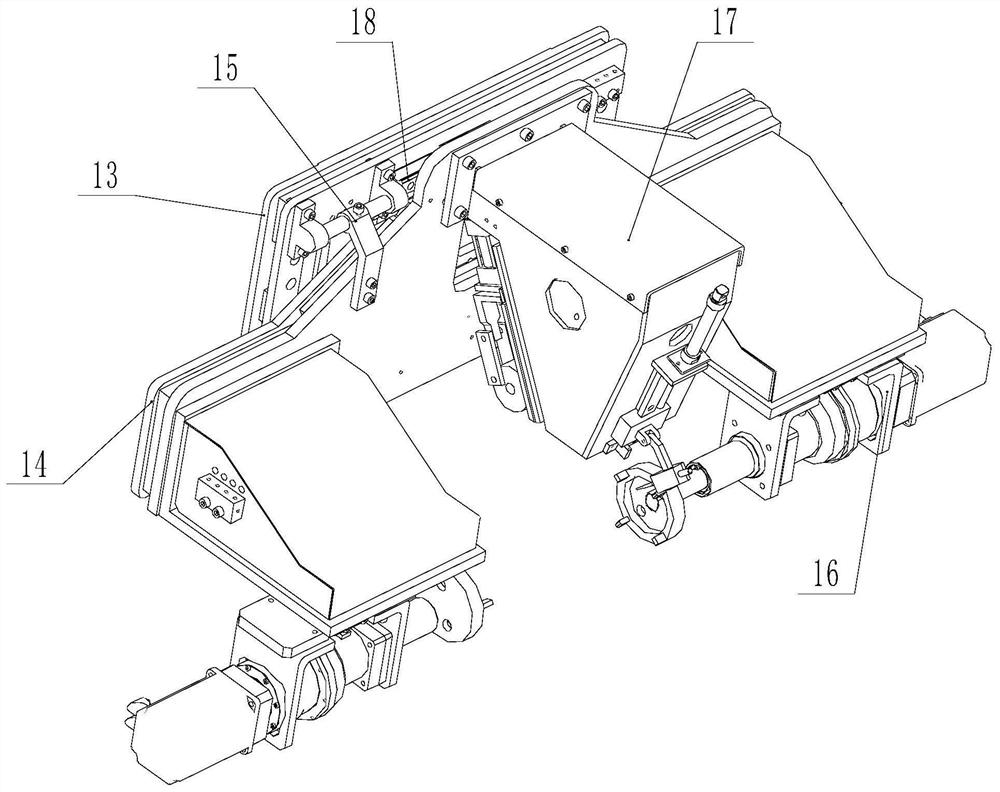

[0033] Such as image 3 As shown, the gear backlash adjustment and measurement device 3 includes a main mounting plate 13, an adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com