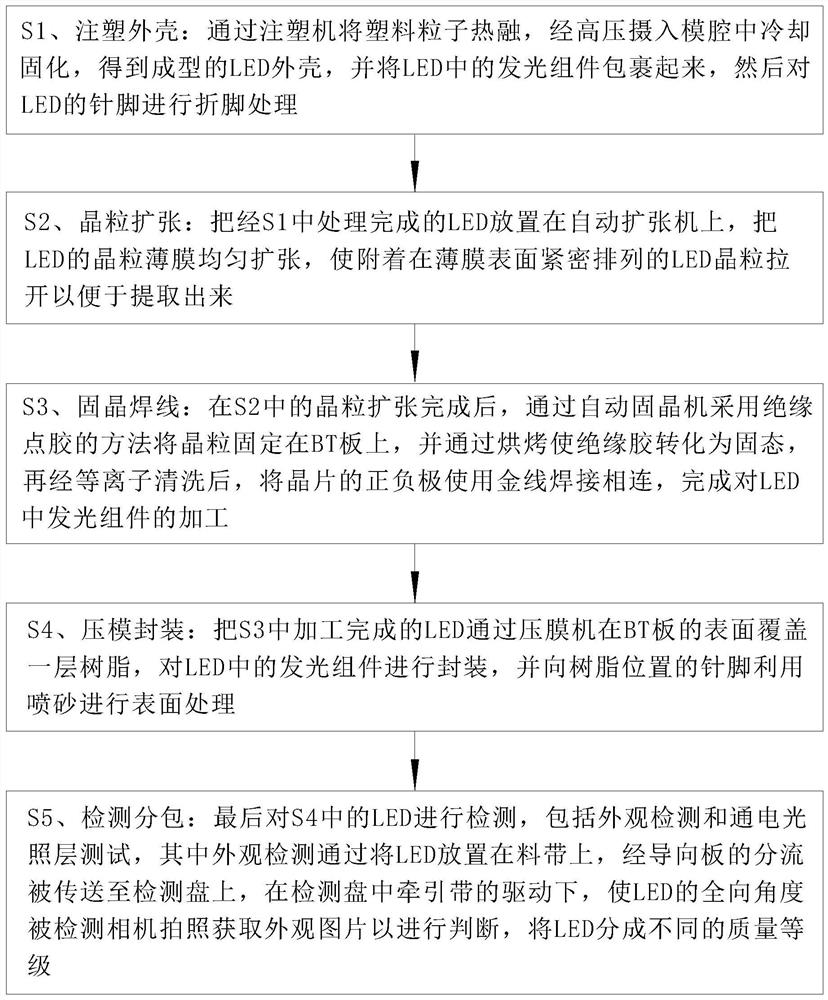

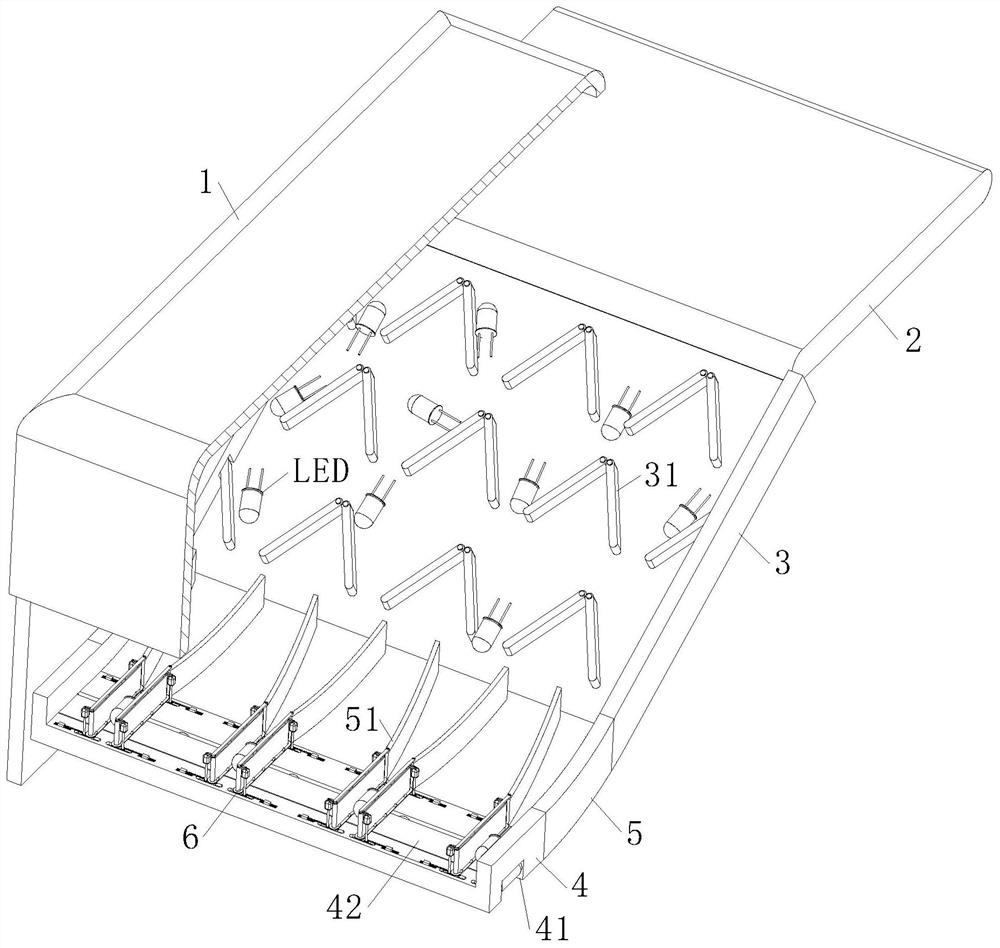

LED appearance detection machine and manufacturing method

An inspection machine and appearance technology, which is applied to measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of increasing the difficulty of image analysis for LED appearance inspection, increasing the amount of image analysis, and the interference of lighting effects of light-emitting components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

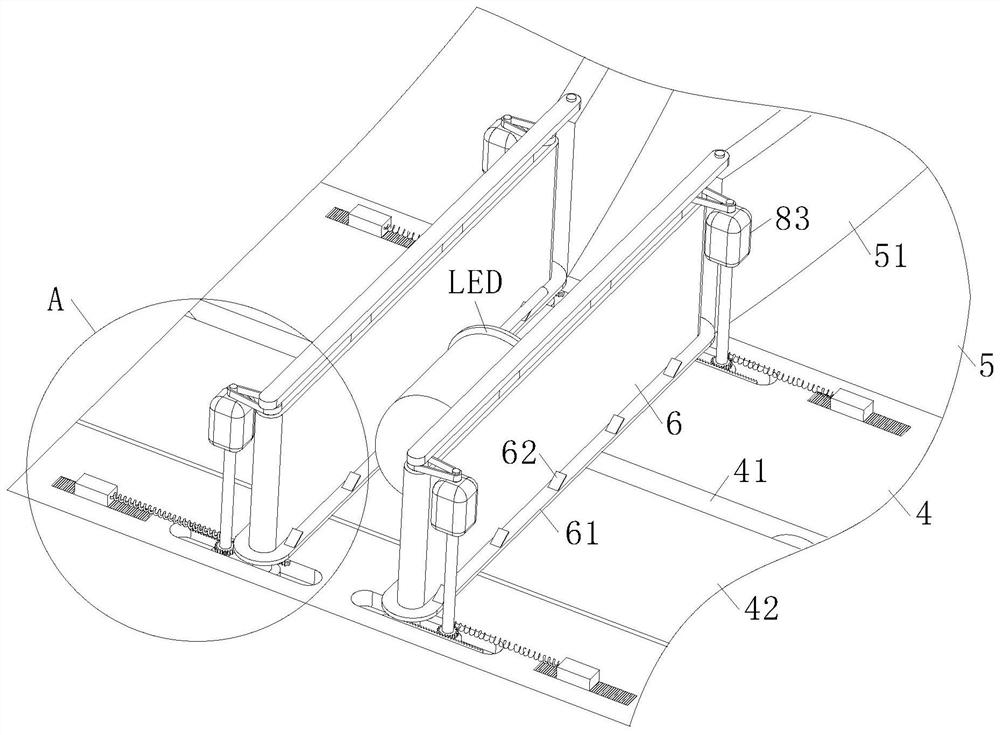

[0032] As an embodiment of the present invention, the two ends of the orientation plate 51 are slidingly installed on the arc-shaped disc 5, and the orientation plate 51 is hingedly connected with the traction roller belt 6; the bottom of the traction roller belt 6 is also provided with a positioning Slider 7, positioning slider 7 is installed in the chute 43 on the detection disc 4; when working, the running traction belt 42 drives the LED to rotate, which will make the LED move to one side of the traction roller belt 6, and on the traction roller The surface of the traction belt 42 between the belts 6 produces reciprocating rolling, which makes the position of the LED in the image taken by the detection camera different, and is not conducive to the appearance detection of the LEDs of different sizes by the traction roller belt 6; The slide block 7 cooperates with the directional plate 51 hingedly connected to the arc-shaped disc 5. When detecting LEDs of different sizes, by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com