Shell packaging structure of IGBT module and method for detecting sealing performance of shell packaging structure

A packaging structure and sealing technology, which can solve the problems of silicone gel leakage, IGBT device scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

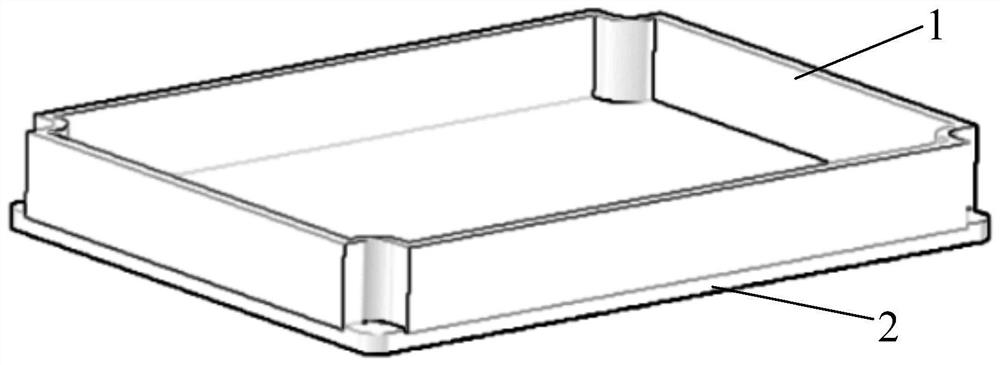

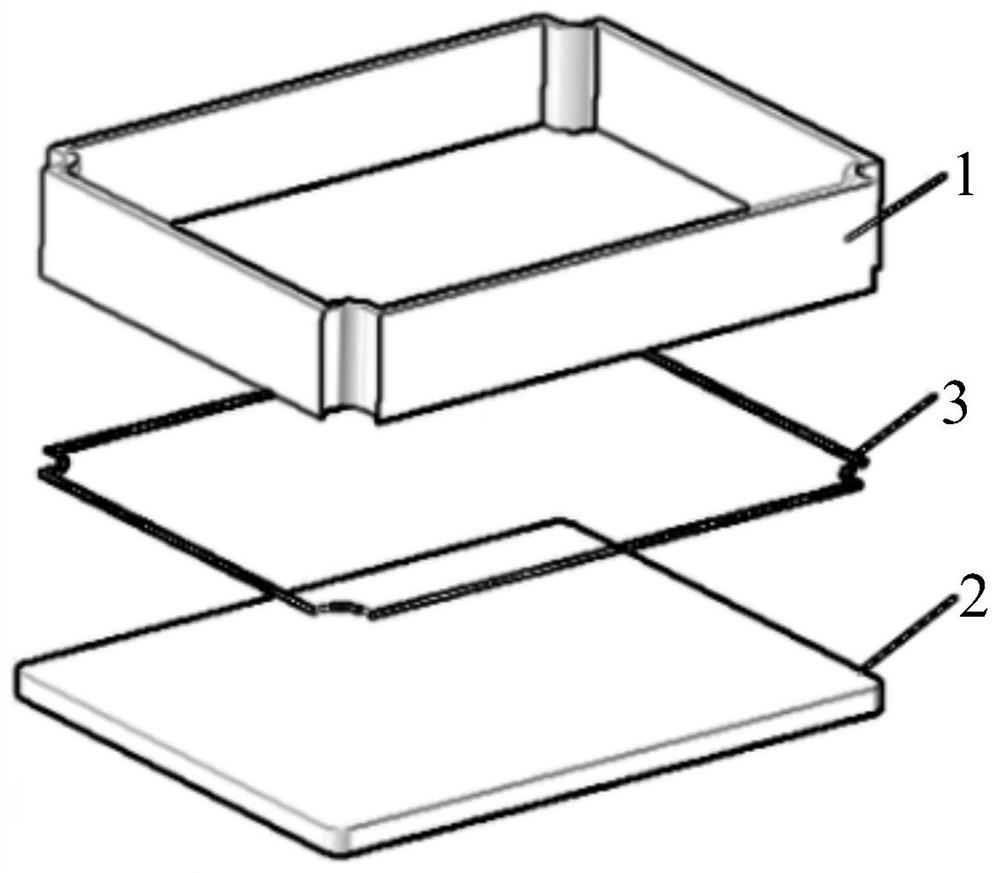

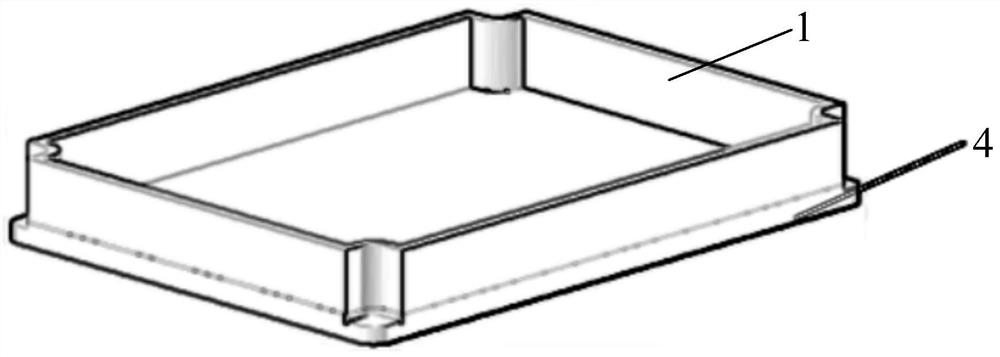

[0028] The present invention provides a shell package structure of an IGBT module, see image 3 As shown, it includes a shell 1 , a bottom plate 2 is arranged under the shell 1 , and the shell 1 and the bottom plate 2 are fixed by an adhesive 3 ;

[0029] Further, the spraying method of the film layer 4 is atomized spraying.

[0030] Furthermore, the thickness of the film layer 4 is 50-100 μm.

Embodiment 2

[0032] On the basis of Embodiment 1, the present invention provides a method for detecting the airtightness of the housing packaging structure of the IGBT module, which is used for the detection of the sealing of the adhesive 3 between the housing 1 and the bottom plate 2 in the housing packaging structure, specifically including :

[0033] 1) Vacuum negative pressure: place the IGBT module coated with the film layer 4 in the vacuum equipment, seal the upper part of the casing 1 and pump the internal pressure to negative pressure, see Figure 4 ;

[0034] 2) Determine whether there is a gap between the shell 1 and the bottom plate 2 according to whether the film layer 4 is damaged: if the film layer 4 is damaged, there is a gap between the shell 1 and the bottom plate 2; if not, there is no gap between the shell 1 and the bottom plate 2.

[0035] Further, in step 1), the cover plate 5 is used to seal the upper part of the housing 1 .

[0036] In this detection method, the pr...

Embodiment 3

[0038] On the basis of Embodiment 1, the present invention provides another method for detecting the airtightness of the housing packaging structure of the IGBT module, which is used for the detection of the sealing of the adhesive 3 between the housing 1 and the bottom plate 2 in the housing packaging structure. Layer 4 is a gas-sensitive film layer, specifically including:

[0039] 1) Vacuum negative pressure: place the IGBT module coated with the gas-sensitive film layer in the vacuum equipment, seal the upper part of the casing 1 and fill it with inert gas, and pump the space pressure outside the IGBT module to negative pressure;

[0040] 2) Determine whether there is a gap between the shell 1 and the bottom plate 2 according to whether there is a reaction phenomenon in the gas-sensitive film layer. If yes, there is a gap between the shell 1 and the bottom plate 2. If not, there is no gap between the shell 1 and the bottom plate 2.

[0041] Further, the coating method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com