LED packaging structure and manufacturing method thereof

A technology of LED packaging and manufacturing methods, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of serious light absorption and low brightness of black glue, and achieve the effects of increasing brightness, improving contrast, and preventing cross-lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

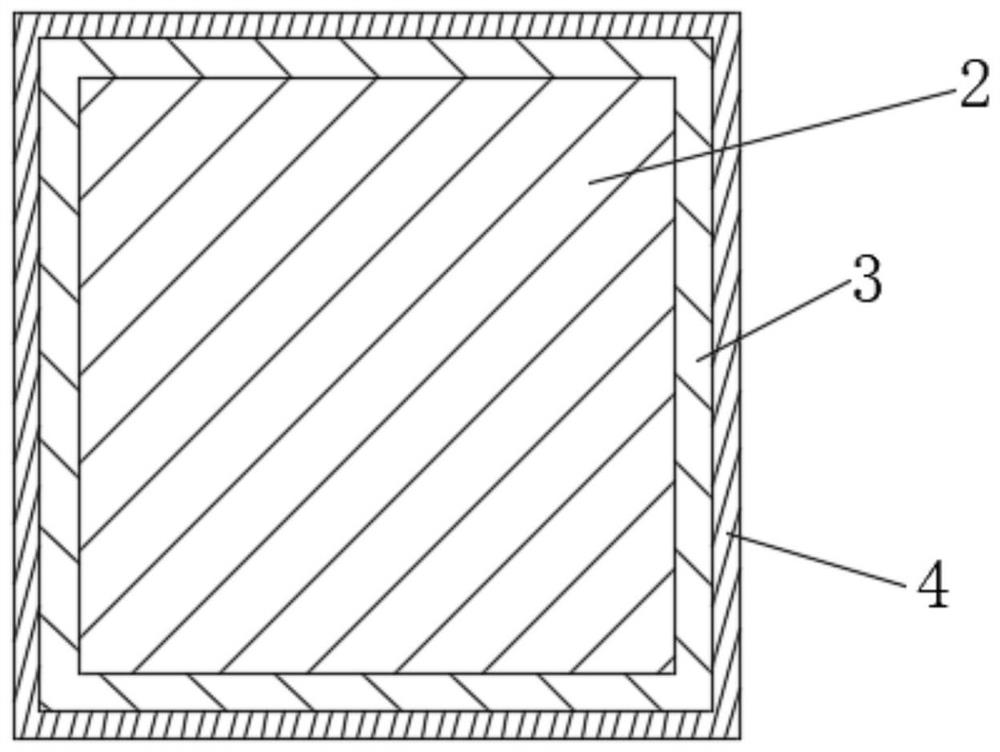

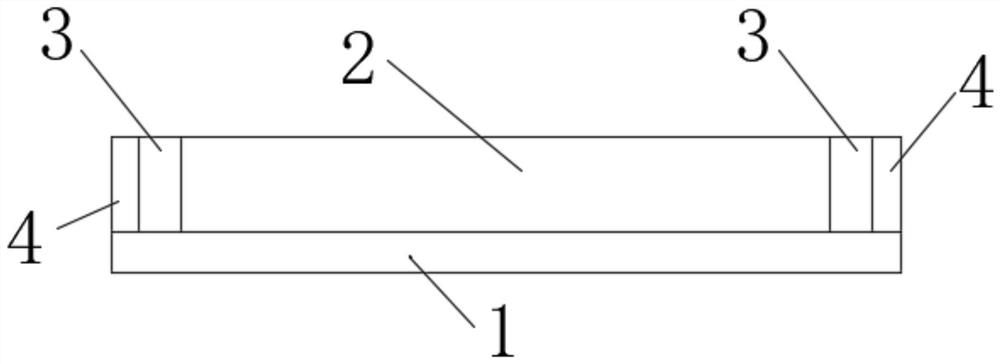

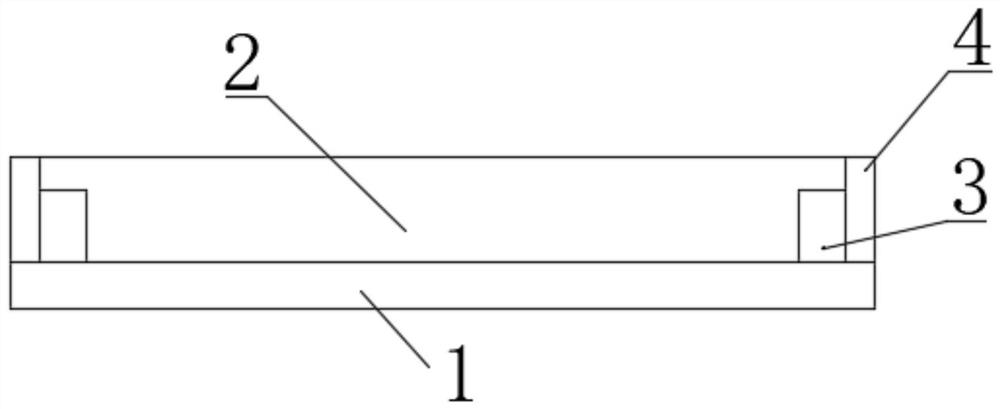

[0042] This embodiment provides a kind of LED encapsulation structure, refer to Figure 1-2 , including a substrate 1, an LED chip, a transparent adhesive layer 2, a white adhesive layer 3, and a black adhesive layer 4; the LED chip is an RGB chip.

[0043] The LED chip (not shown) is arranged on the substrate 1; the transparent adhesive layer 2 is laid on the substrate 1 and coated on the LED chip; the transparent adhesive layer 2 is used to diverge the light emitted by the LED chip to improve the light color uniformity of the LED properties; the white glue layer 3 is arranged around the transparent glue layer 2, and is used to reflect the light that is diverged to the white glue layer 3, avoiding a large amount of light being absorbed by the black glue layer 4, and improving the brightness of the LED; the black glue layer 4 Surrounded and arranged outside the white glue layer 3, the contrast can be improved, and the light emitted by other surrounding LED chips can be absorbe...

Embodiment 2

[0047] This embodiment provides a method for manufacturing the LED package structure as described in Embodiment 1, comprising the following steps:

[0048] refer to Figure 4-6 , step S10, surround the first wall 5 around the edge of the substrate 1, the first wall 5 and the substrate 1 form a groove 6, add liquid transparent glue into the groove 6, and form a transparent glue after the liquid transparent glue is cured Layer 2;

[0049] Specifically, there are multiple LED chips (not shown) on the substrate 1; after the first wall 5 is set on the substrate 1, the first wall 5 forms a groove 6 with the substrate 1, and liquid transparent glue is added to form a transparent glue layer. 2.

[0050] In some embodiments, after the step of S10, it also includes

[0051] S11, polishing the surface of the transparent adhesive layer 2 to a preset target height.

[0052] refer to Figure 7 , S20, slotting the transparent adhesive layer 2, the surface of the transparent adhesive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com