Forming method of image sensor

A technology of image sensors and doped regions, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems that the electrical performance of image sensors needs to be improved, and achieve the effect of increasing the channel length and suppressing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] As mentioned in the background, the performance of the image sensor formed by the prior art is relatively poor.

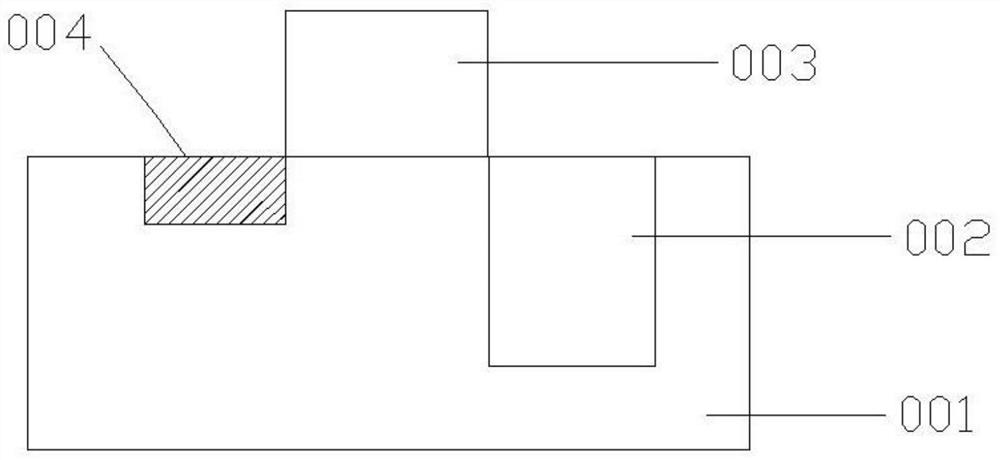

[0024] figure 1 It is a schematic diagram of a partial structure of an image sensor in the prior art, and the image sensor includes: a semiconductor substrate 001; an overflow gate structure 002 located on the semiconductor substrate 001; a diode located in the semiconductor substrate 001 on one side of the overflow gate structure 002 The doped region 003; the overflow drain region 004 located in the semiconductor substrate 001 on the other side of the overflow gate structure 002, and the overflow drain region 004 is electrically connected to the power line.

[0025] The overflow transistor PG Y The role includes: overflow transistor PG Y The drain of the VDD needs to be connected to the power supply line VDD at all times, and will overflow the transistor PG during the clearing sequence step Y Turn on to empty the charge in the photodiode.

[0026] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com