A continuous casting method for reducing large-size inclusions in the surface layer of aluminum-containing steel slabs

A technology of large-size and inclusions is applied in the field of continuous casting to reduce large-size inclusions on the surface of aluminum-containing steel billets, which can solve the problem of not reducing the content of large-size inclusions on the surface of the billet, reducing the occurrence rate of slag, The effect of reducing the incidence of surface defects and reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

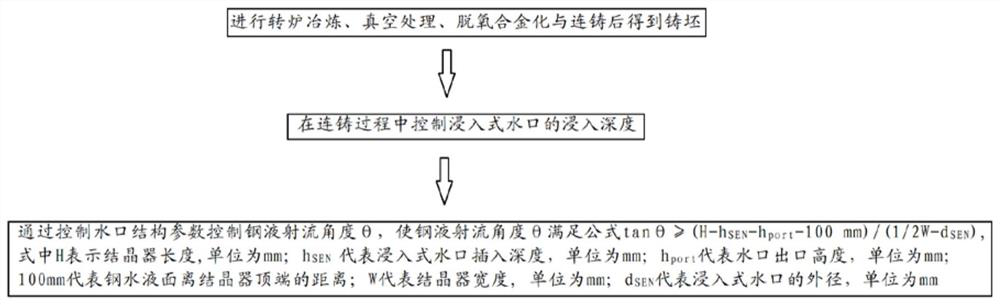

[0016] see figure 1 A continuous casting method for reducing large-sized inclusions in the surface layer of aluminum-containing steel slabs provided by an embodiment of the present invention includes the following steps:

[0017] The billets are obtained after converter smelting, vacuum treatment, deoxidation alloying and continuous casting.

[0018] Controls the immersion depth of submerged nozzles during continuous casting.

[0019] Control the molten steel jet angle θ so that the molten steel jet angle θ satisfies the following formula tanθ≥

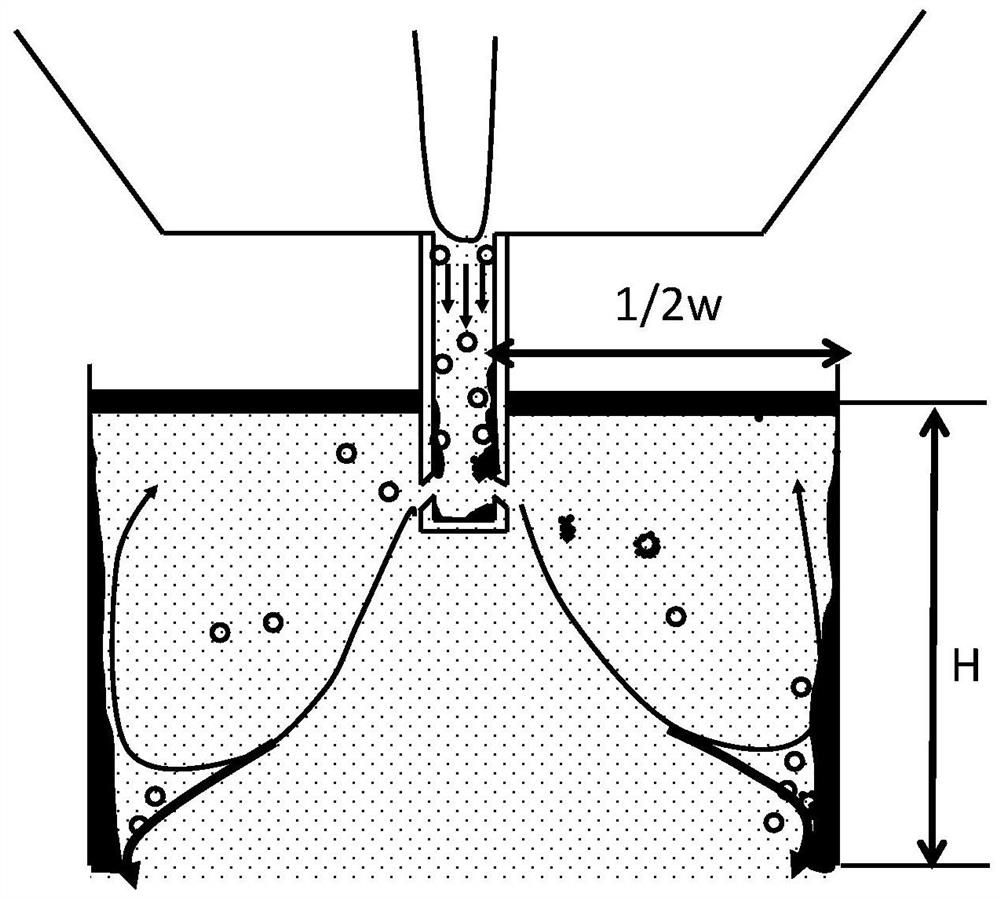

[0020] (H-h SEN -h port -100mm) / (1 / 2W-d SEN ), where H represents the crystallizer length, mm; h SEN Represents the insertion depth of the submerged nozzle, mm; h port Represents the nozzle outlet height, mm; 100mm represents the distance between the molten steel surface and the top of the mold; W represents the mold width, mm; d SEN Represents the outer diameter of the submerged nozzle, mm.

[0021] Specific embodiments of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com