Ejection-retrievable towed ram-parafoil

A towed and parafoil technology, applied in the field of towed parafoils, can solve problems such as unsafe flying, reduced service life of the parafoil, and damage to the parafoil by scraping, so as to avoid damage, ensure directionality and consistency, and improve the The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

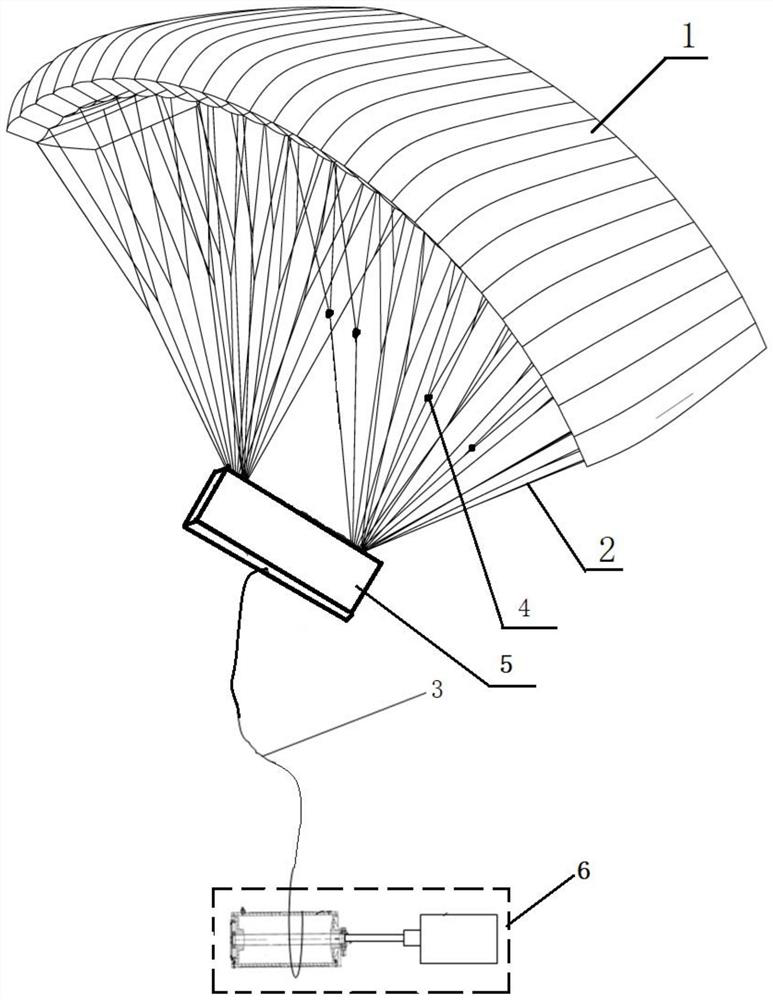

[0058] This embodiment provides a towed parafoil that can be ejected and recovered repeatedly. The parafoil can be ejected into the air through the ejection recovery device, and the parafoil can be recovered to store energy for the next parachute when it falls back, so that the requirements for the parafoil site are greatly reduced. Suitable for more complex terrain parachute.

[0059] The traction-type stamping parafoil that can be ejected and recovered includes: parafoil, retractable device 6 and ejected recovery device 17, wherein the ejected recovered device 17 is arranged on the inside of the load compartment 5 of the parafoil or on the upper end surface of the load compartment 5; the retractable device 6 The parafoil is towed by the photoelectric mooring cable 3 . During use, retractable device 6 can be installed on the car / ship.

[0060] like figure 1 As shown, the parafoil includes: a canopy 1 , a parafoil rope 2 and a load compartment 5 . The canopy 1 is connected ...

Embodiment 2

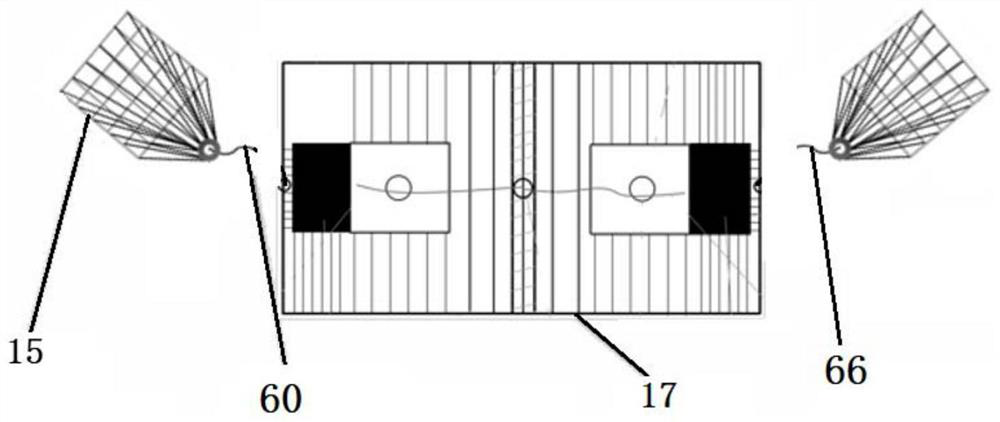

[0079] like Figure 7 As shown, the retracting device includes: an electronic control unit, a base 23 , and a cable retracting unit 18 installed on the base 23 , a cable discharge unit 19 and a traction mechanism 4 . The automatic pulling and releasing device is connected to the load compartment through the photoelectric mooring cable 3 (the photoelectric mooring cable 3 is used as the carrier of optical fiber signal transmission and current conduction), and the retraction and release of the photoelectric mooring cable 3 is controlled to control the parafoil in the air. the height of. Specifically, the photoelectric mooring cable 3 wound on the retractable cable unit 18 is connected to the parafoil after passing through the cable discharge unit 19 and the traction mechanism 21 in sequence.

[0080] Wherein the retracting cable unit 18 is used for storing the photoelectric mooring cable 3 and the photoelectric mooring cable 3 retracting, specifically includes: a cable winding ...

Embodiment 3

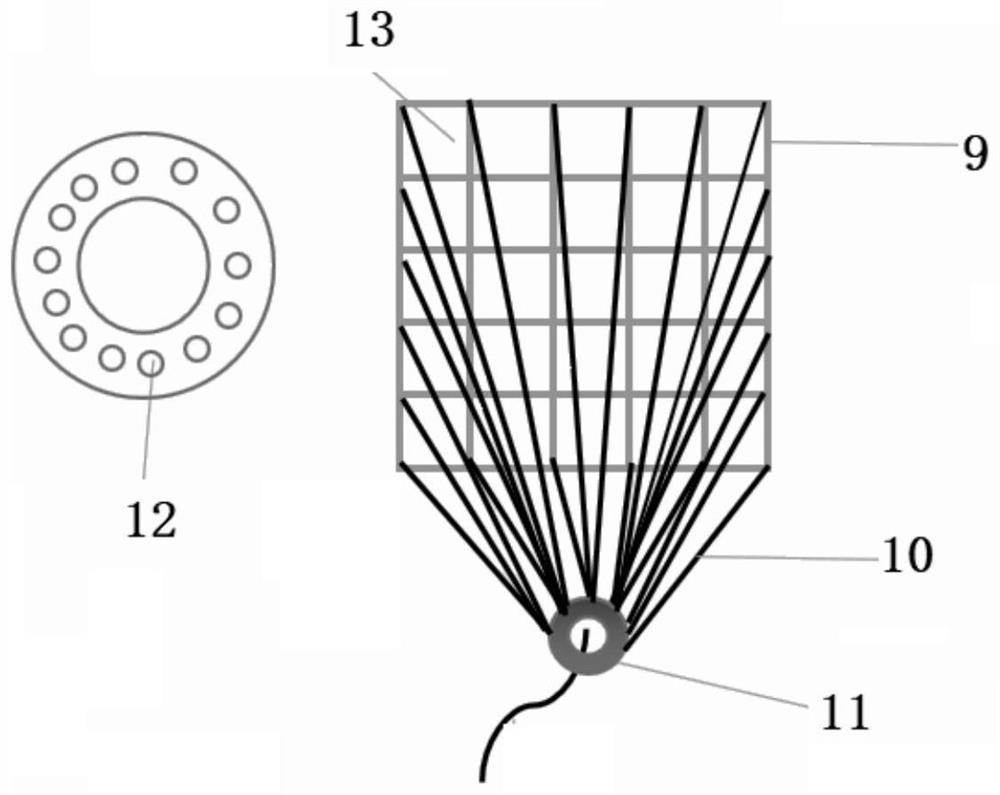

[0089] On the basis of the above-mentioned embodiment 2, in order to realize that the parafoil can be pulled in any direction through the photoelectric mooring cable 3 and avoid damage caused by the too small bending angle of the photoelectric mooring cable 3 . A cable unwinding mechanism 24 is set in the automatic retracting device.

[0090] like Figure 7 As shown, the cable release mechanism 24 is arranged at the cable outlet of the traction mechanism 21, that is, the photoelectric tethered cable 3 is connected to the parafoil through the cable release mechanism 24 after being drawn out from the traction mechanism 21. The cable unwinding mechanism 24 includes: two or more "well" wheels arranged along the cable outlet direction of the photoelectric mooring cable 3, and the photoelectric mooring cable 3 passes through the cable hole 33 in the middle of each "well" wheel in turn; And along the cable outlet direction of optoelectronic mooring cable 3, the aperture of the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com