Rigid landfill pretreatment process for hazardous waste

A pretreatment, rigid technology, applied in landfill technology, chemical/physical process, solid waste removal, etc., can solve the problem of not having pretreatment equipment and process, and achieve the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly.

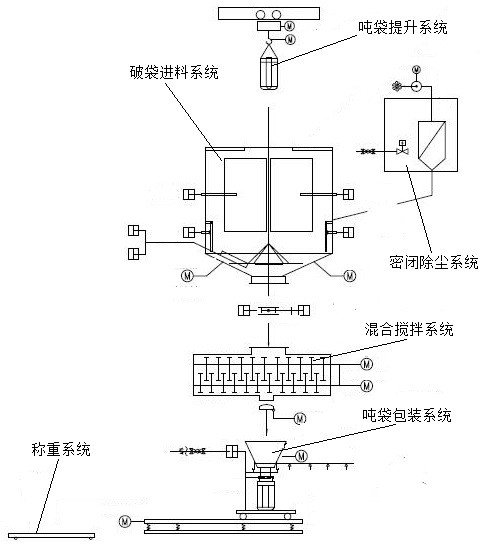

[0018] see figure 1 As shown, the embodiment of the present invention includes: a hazardous waste rigid landfill pretreatment process, including a large bag lifting system, a broken bag feeding system, a closed dust removal system, a mixing system, a large bag packaging system, a weighing system and a PLC Control system, the specific steps are as follows:

[0019] 1) Ton bag lifting system: bridge crane is used to manually lift ton bags into the automatic bag unpacking machine;

[0020] 2) Bag breaking feeding system: The opening and closing door of the automatic bag unpacking machine is controlled by the door opening cylinder. Through it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com