Coal water slurry process burner

A process burner and coal-water slurry technology, which is applied in the direction of granular/powder fuel gasification, etc., can solve the problems of poor wear resistance and shortened working life of coal-water slurry process burners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

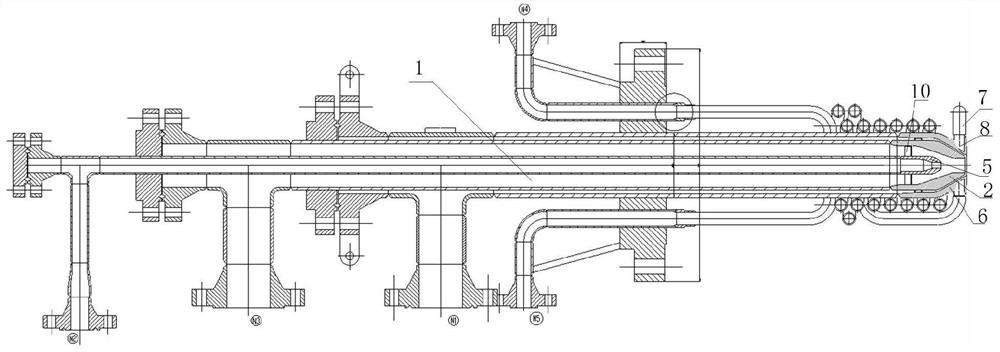

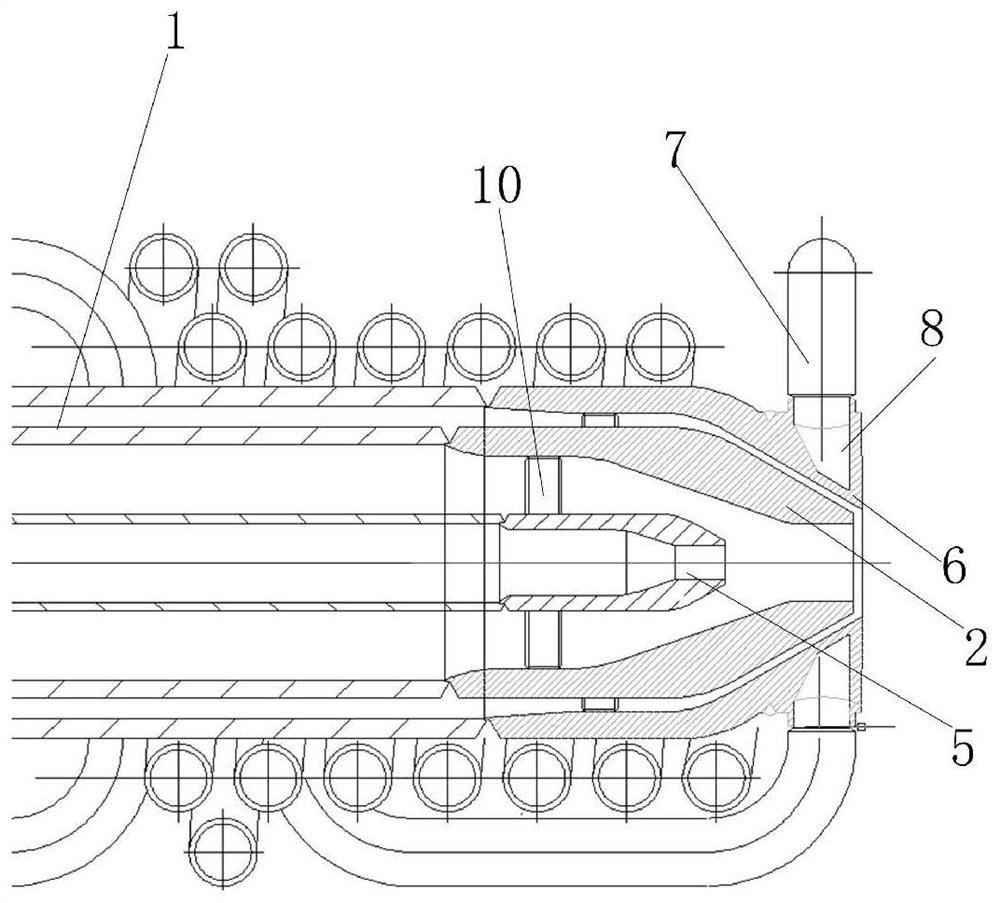

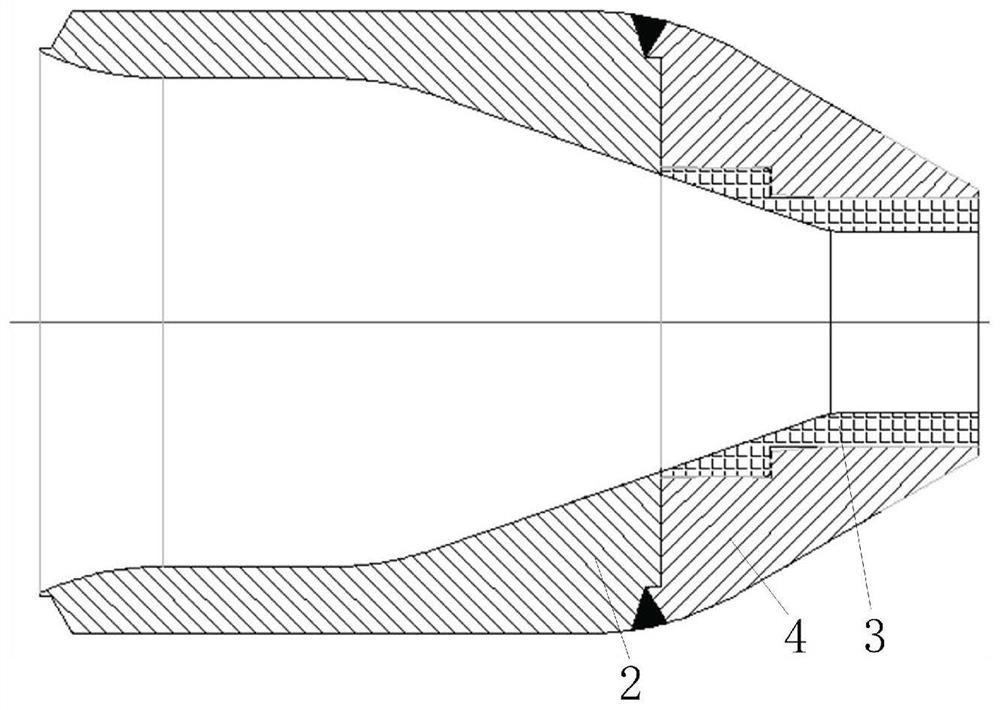

[0026] See Figure 1-Figure 7 , the embodiment of the present invention provides a coal water slurry process burner, comprising: a burner body 1, a burner head is arranged at one end of the burner body 1; a water burner is arranged in the burner head Coal slurry nozzle 2; the inner wall of the outlet of the coal-water slurry nozzle 2 is provided with a wear-resistant layer 3 extending to the outlet end; the wear-resistant layer 3 and the inner side of the outlet of the coal-water slurry nozzle 2 The surface formed by the wall is a smooth surface.

[0027] It should be noted that the above-mentioned wear-resistant layer 3 can be a ceramic layer made of wear-resistant ceramic material, or it can be a wear-resistant layer 3 made of other materials with good wear resistance and high temperature resistance, or it can be wear-resistant A wear-resistant layer 3 supported by a high-temperature composite material; this embodiment does not specifically limit the type, model, etc. of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com