A steel mesh component based on automatic spot welding technology

A steel mesh and automatic spot welding technology, which is applied to building components, structural elements, building reinforcements, etc., can solve the problems of reduced performance of reinforced concrete structures, lack of steel mesh components, and violation of economics and practicality, etc., to achieve space occupancy Low, easy to transport, reduce the effect of work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

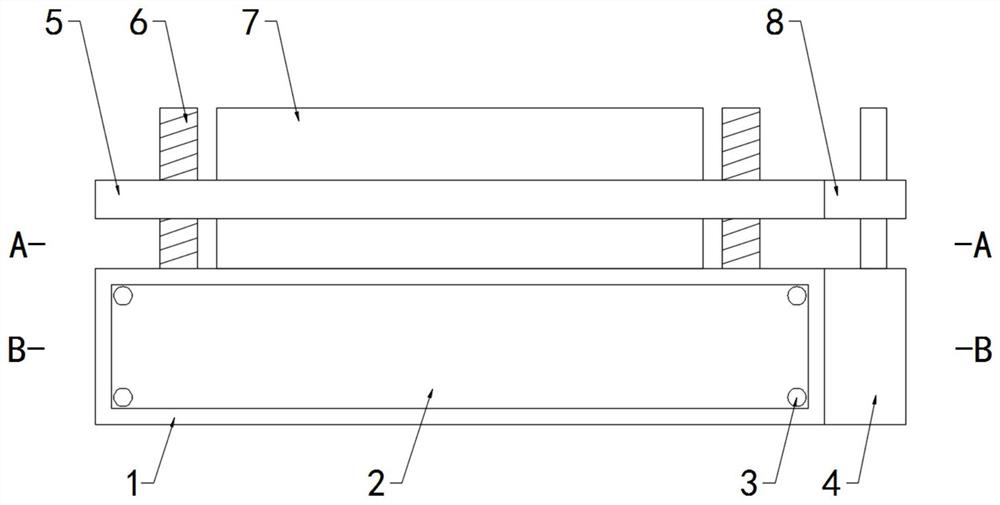

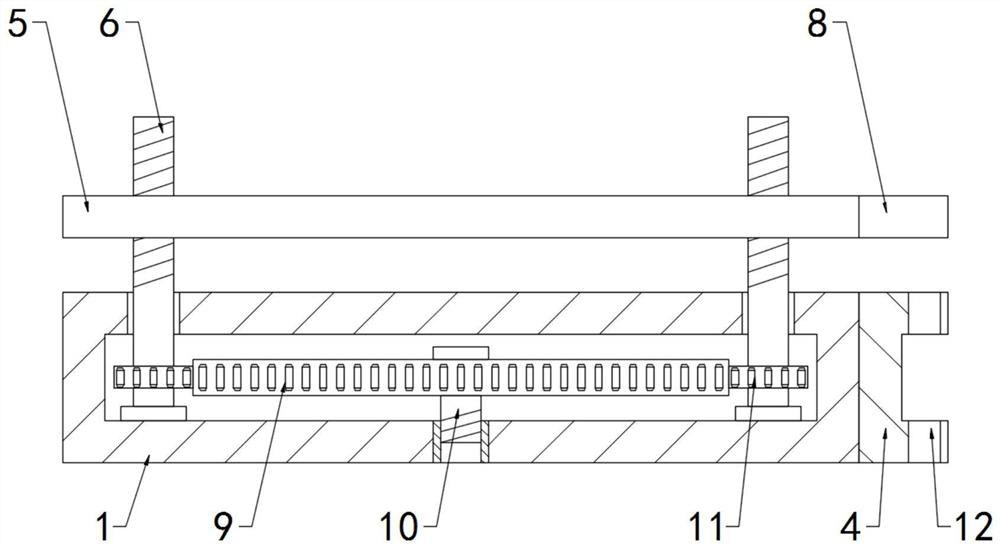

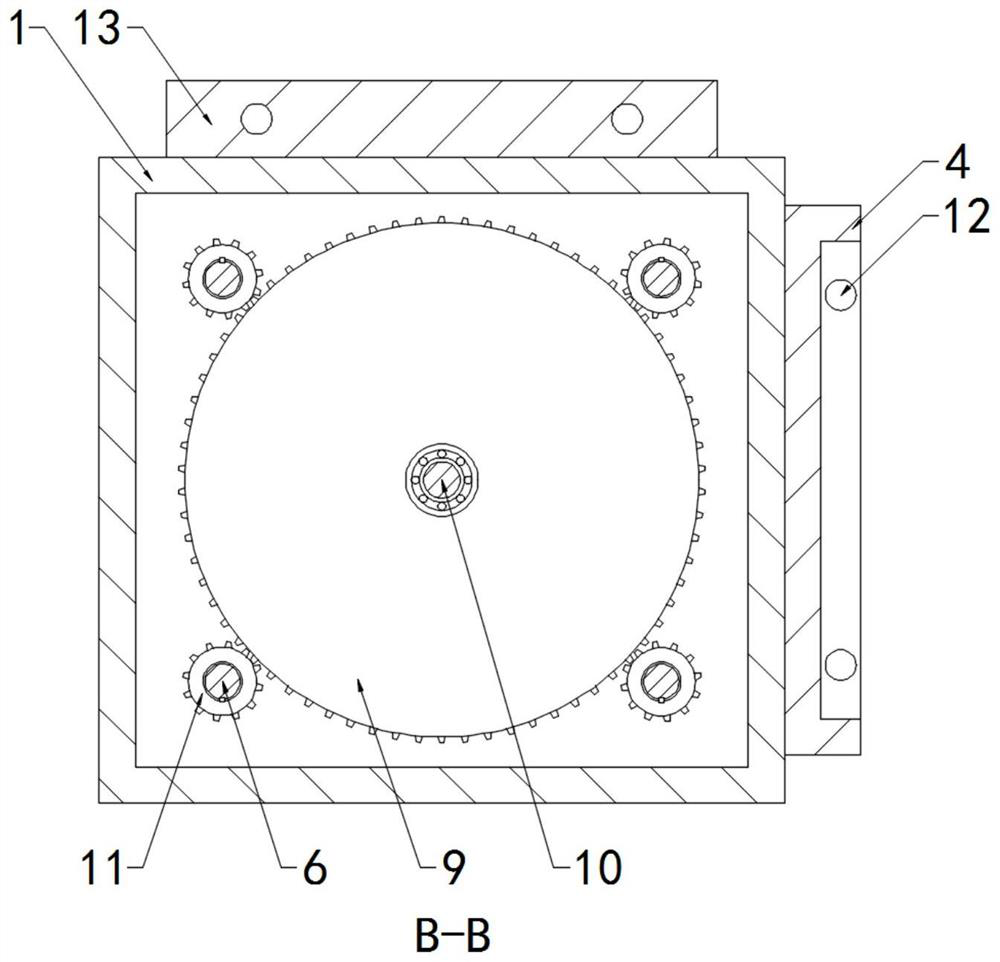

[0038] see Figure 1-5, a reinforcement mesh member based on automatic spot welding technology, including a base 1 and longitudinal reinforcement bars 17 and transverse reinforcement bars 18 distributed in a mesh shape, a plurality of longitudinal reinforcement bars 17 and transverse reinforcement bars 18 are welded at the intersection, and the longitudinal reinforcement bars 17 and A positioning frame 5 is welded on the outer side of the reinforcement mesh composed of transverse reinforcement bars 18, and corner reinforcing ribs 20 are welded between the surface walls on both sides of the positioning frame 5 to prevent the positioning frame from expanding and bursting after pouring concrete, and to improve the reinforcement mesh. The strength of the sheet, the obliquely-stayed rib 19 is welded between the two corner ribs 20 on the diagonal, and the two obliquely-stayed ribs 19 are welded at the intersection, the obliquely-stayed rib 19 and the corner rib 20 is symmetrically a...

Embodiment 2

[0041] The difference from Example 1 is that

[0042] see Figure 4 One side of the positioning frame 5 is fixedly connected with a connecting frame 8, and a rotating roller 15 is installed between the inner surface walls at both ends of the connecting frame 8, and a metal mesh 16 is wound around the outer side of the rotating roller 15, and the metal mesh 16 is drawn to cover the existing Concrete is poured above the steel mesh sheet, and concrete is poured twice on the metal mesh 16 to increase the pouring density of the concrete, further improve the structural performance of the reinforced concrete formed between the concrete and the steel mesh sheet, increase the structural stability, and transfer The roller 15 and the metal mesh 16 are installed on one side of the positioning frame 5, the space occupancy rate is low, and the transportation difficulty is not increased.

Embodiment 3

[0044] The difference from Example 1 is that

[0045] see Figure 4 with Figure 5 , the positioning frame 5 near the outer edge and the top of the connecting frame 8 are provided with a fixed through groove 14, and the corresponding position on the base 1 is provided with a fixed groove 21, and a unified stopper is inserted between the fixed through groove 14 and the fixed groove 21. Plate 7, when concrete is poured on the steel mesh sheet, the loss speed of concrete is slowed down by the baffle plate 7, the waste of concrete is reduced, the use cost is reduced, the bonding speed between the concrete and the steel mesh sheet is increased, and the work efficiency is improved. Among them, according to the actual The use situation selects the baffle plate 7 of suitable size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com