Pressure relief system and container, building, enclosure or cubicle including pressure relief system

A release system, building technology, applied in the setting of switchgear, switchgear, electrical components, etc., can solve problems such as time delay, and achieve the effects of saving time and cost, avoiding damage, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] According to embodiments described herein, an actively actuated pressure relief system is provided that is particularly useful in containers, buildings, enclosures, and compartments with electrical devices. For example, actively driven pressure relief systems can be used in power systems, grids, in installed products, in semiconductor applications, with power converters, switchgear, circuit breakers, motors and generators, and in other used in industrial applications. In general, actively driven pressure relief systems as described herein can be used with high power rectifiers and high current rectifiers.

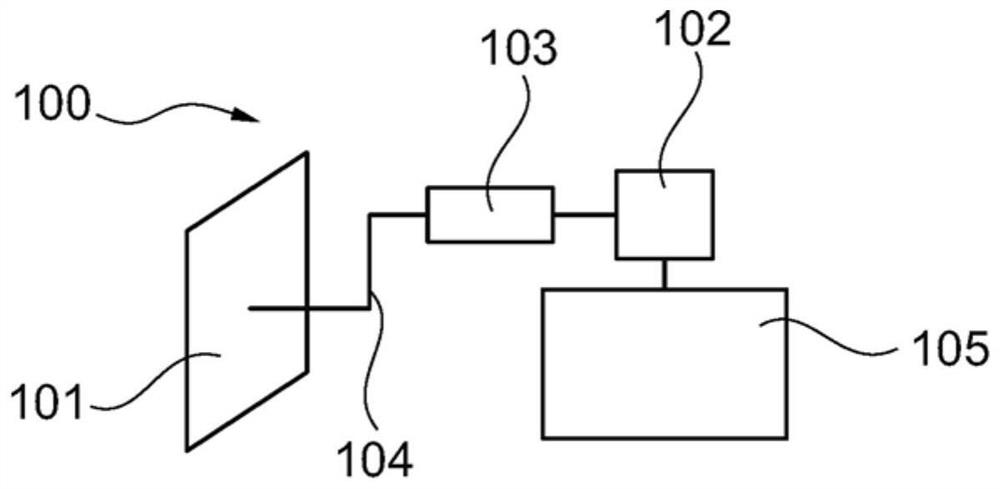

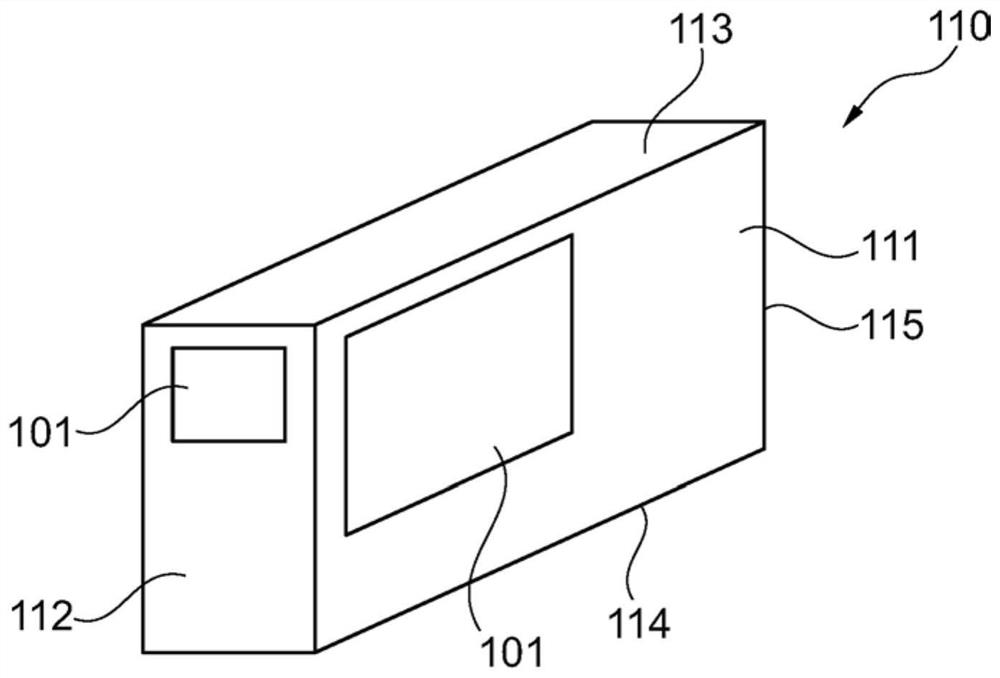

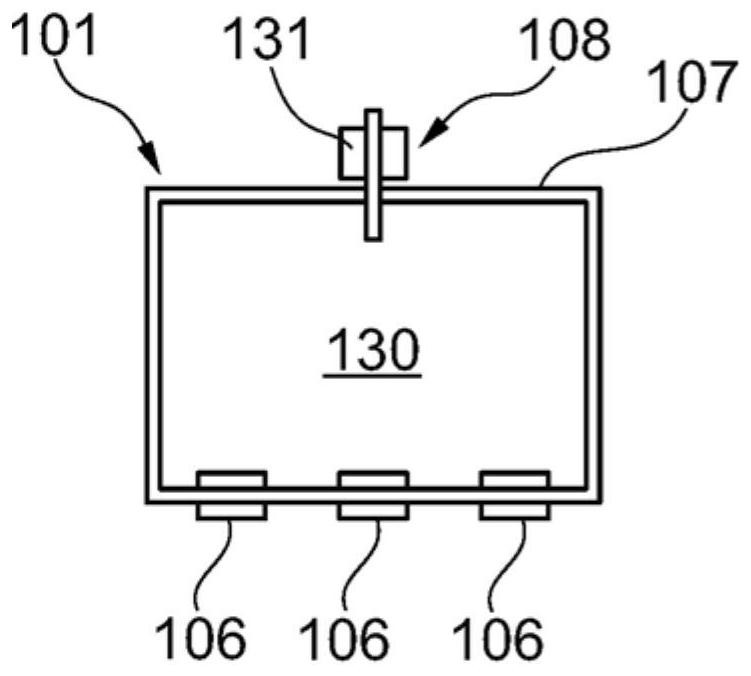

[0022] figure 1 A schematic diagram of an actively actuated pressure relief system 100 and panel 101 according to embodiments described herein is shown. Such as figure 1 The actively driven pressure relief system 100 shown has a fault detection device 102 , in particular an arc fault detection device, and a trigger unit 103 . In some embodiments, the actively ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com