Feather correcting device of feather inserting machine for badminton production

A technology of feather inserting machine and shuttlecock, which is applied in the direction of ball games and sports accessories, etc. It can solve the problems of reducing the production efficiency of shuttlecock processing, affecting the overall quality of shuttlecock, and tilting the angle of feather, so as to improve the quality of production and facilitate the insertion of feathers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

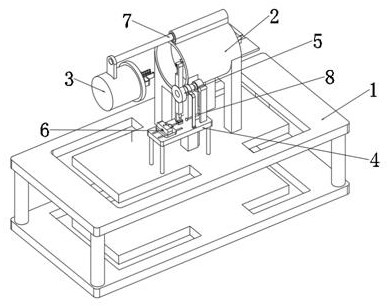

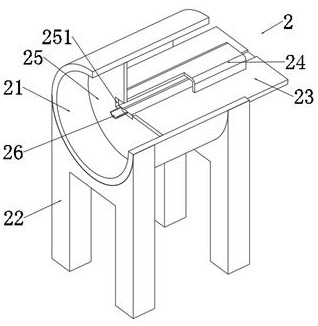

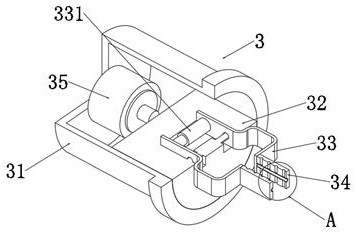

[0024]SeeFigure 1-8The present invention provides a technical solution: a furminton production plug-in mechanism, including a table 1, a tip end side of the table 1 fixed to a conductive mechanism 2, and the top end of the table 1 is fixed The electrical telescopic rod 7 is fixedly mounted between the fixing mechanism 3, the conductive mechanism 2, and the receiving mechanism 3 mounted with the conductive mechanism 2, and the top end of the table 1 is fixedly mounted, and the top end of the base 4 is fixedly mounted. On one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com