Automatic deep cavity cleaning device

An automatic cleaning and deep cavity technology, which is used in devices that apply liquid to the surface, cleaning hollow objects, cleaning methods and utensils, etc. problems, to achieve the effect of facilitating rapid replacement, strengthening cleaning and protection effects, and smoothing the cleaning process without lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

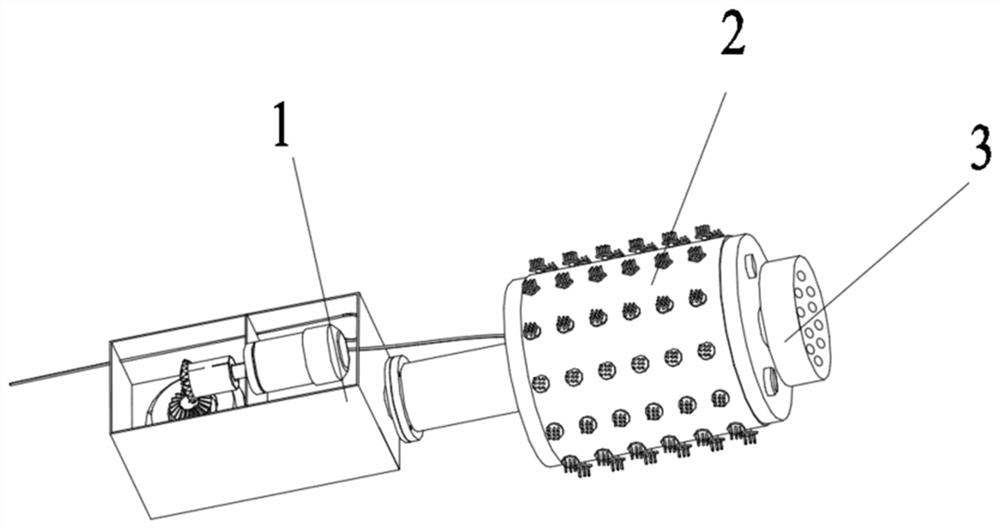

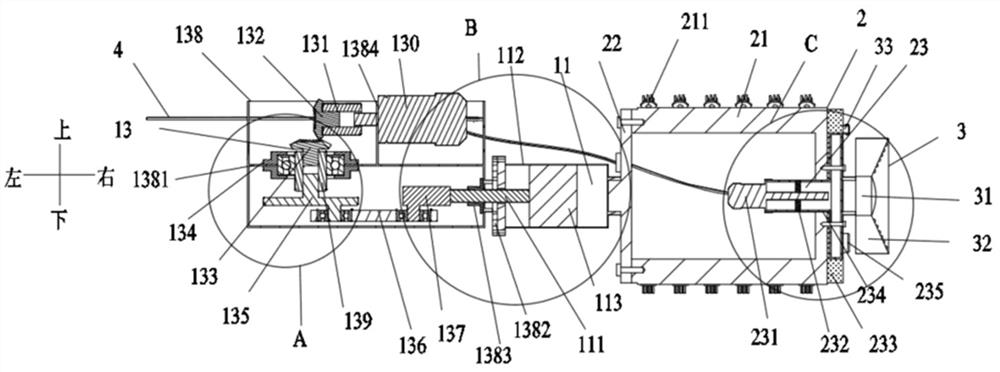

[0036] Embodiment one, such as Figure 1 to Figure 6 As shown, a deep cavity automatic cleaning device includes an actuator, and the actuator includes a power module 1, a cleaning module 2 and a detection module 3; one end of the cleaning module 2 is detachably and fixedly connected to the power module 1, and the other end is connected to the power module 1. The detection module 3 is detachably fixedly connected.

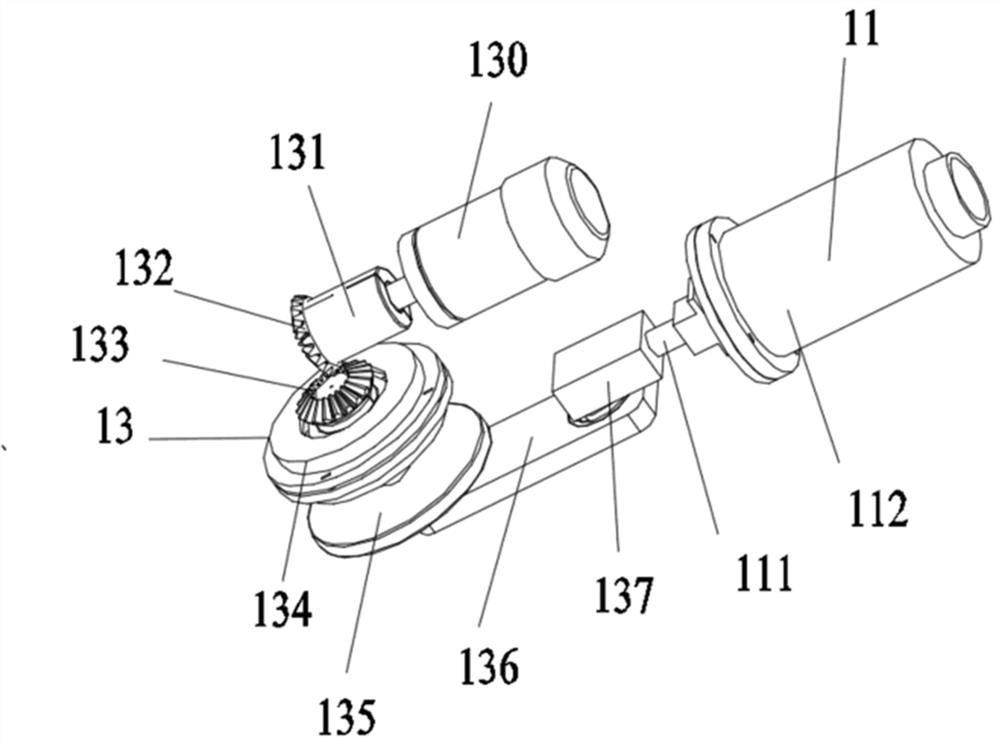

[0037] Further, the power module 1 includes a first power part 13 and a piston cylinder 11, the piston cylinder 11 includes a cylinder body 112, a piston rod 111 and a piston 113, and the cylinder body 112 is fixedly connected to the first power part 13 , the piston 113 is arranged in the cylinder body 112 and can reciprocate, one end of the piston rod 111 extends into the cylinder body 112 and is fixedly connected with the piston 113, and the other end extends out of the cylinder body 112 to drive the piston 113 to reciprocate Movement; one end of the cylinder bod...

Embodiment 2

[0048] Embodiment two, such as Figure 7 and Figure 8 As shown, the power part of the power module 1 of this embodiment is different from that of the first embodiment, and is used to solve the situation that the center of gravity of the power part shifts in the first embodiment, which causes the actuator to shake slightly when moving forward. The power module 1 includes a second power part 12 and Piston cylinder 11, the second power part 12 comprises support 121, second motor 122, connecting plate 123, slide block 124, guide rail 125 and fixed plate 126, and support 121 is L-shaped, and bottom plate end is fixedly connected with fixed plate 126, Forming a U shape, the outer side of the fixing plate 126 is fixedly connected to the first connecting end 1121, and the piston rod 111 passes through the fixing plate 126 and is connected to the second motor 122. The second motor 122 is a voice coil motor and includes a fixed end and an output end. The fixed end is a magnet, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com