Inclined shaft efficient accurate grinding machine

A kind of grinding machine, high-efficiency technology, applied in the direction of grinding frame, grinding machine parts, machine tools suitable for grinding the edge of workpiece, etc., can solve the problems of endangering the health of operators, low efficiency, and low efficiency of grinding processing , to achieve the effect of ensuring health and avoiding flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] next combined with Figure 1-6 A specific embodiment of the present invention is described in detail.

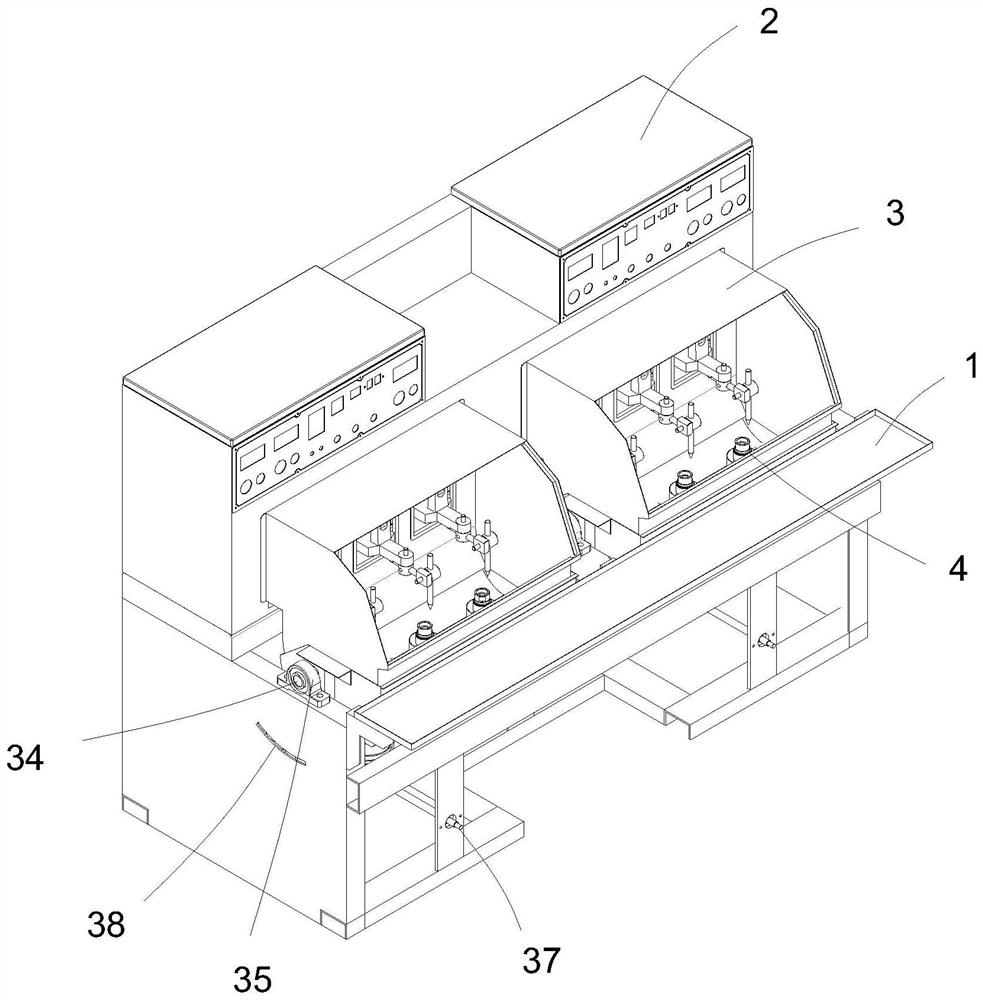

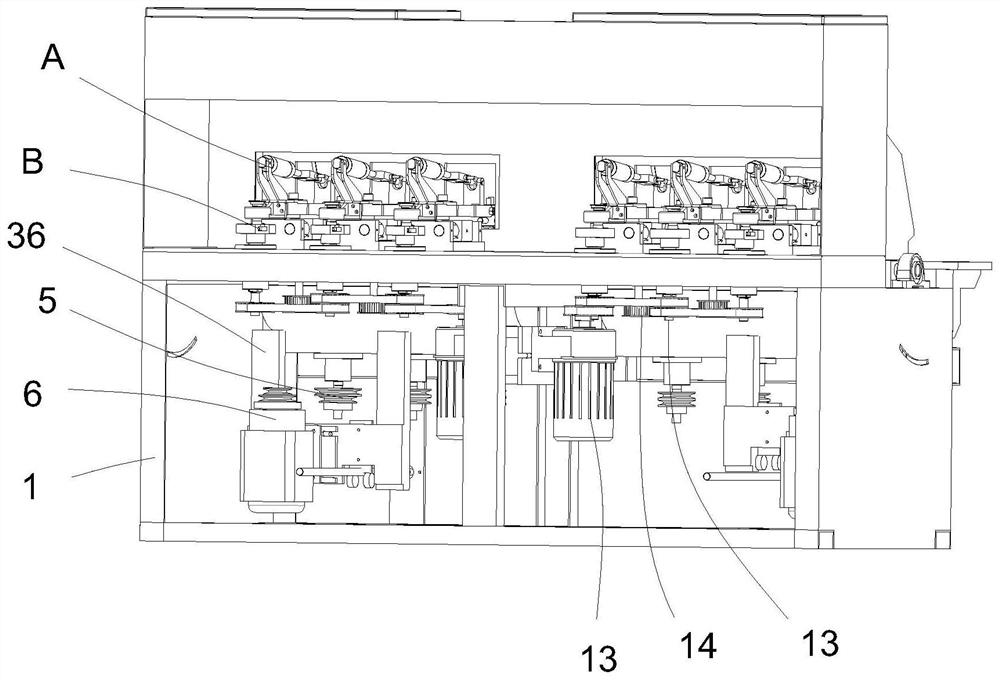

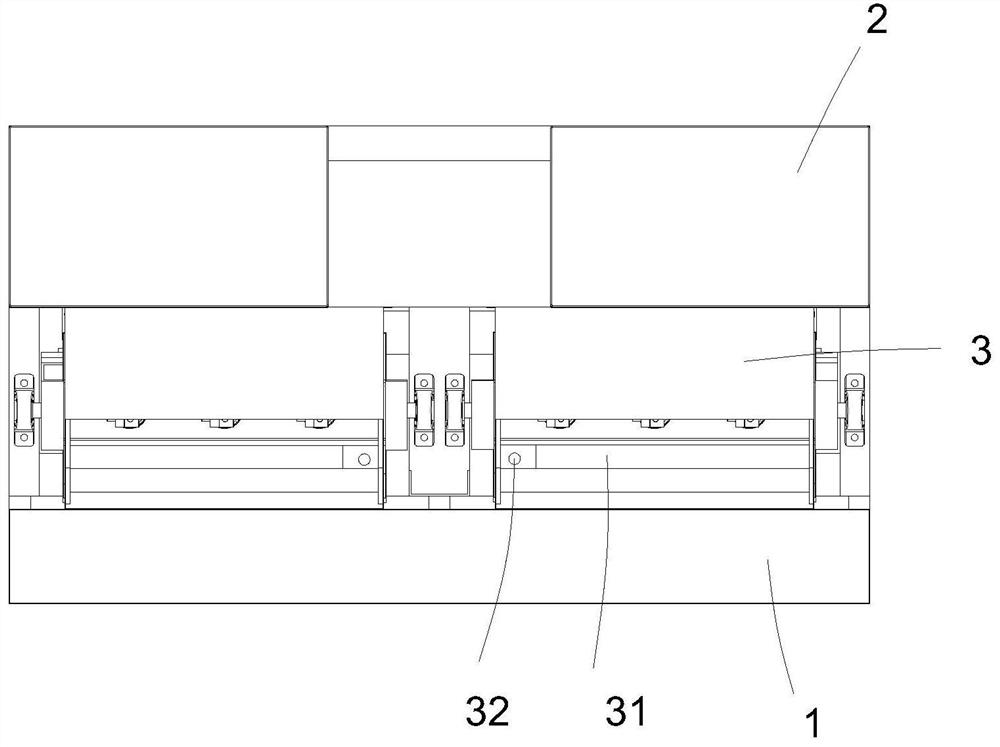

[0024] Reference attached Figure 1-4 , a high-efficiency oblique-axis fine grinding machine, including an organic platform 1 and a plurality of grinding machine positions arranged on the machine platform 1, and also includes a control box 2 arranged on the machine platform, and the machine platform 1 is facing the operator. Each grinding machine position at the operating surface is provided with an isolation cover 3, and the grinding head assembly of the grinding machine position is located in the isolation cover 3. The grinding head assembly includes a grinding head, and the bottom of the isolation cover 3 is provided with a rotating position facing the grinding head. 4. The raw material to be ground is placed in the rotary table 4. The rotary position 4 passes through the isolation cover 3 through the connecting rod and is connected to the first pulley 5 located u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com