Reciprocating grinder automatic feeding and grinding clamp

An automatic feeding and reciprocating technology, which is applied in the direction of grinding workpiece brackets, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of not meeting the needs of slide grinding, affecting the increase in production cycle yield of slides, grinding Eliminate problems such as long fixture adjustment time, achieve the effect of improving equipment adjustment time and product processing quality, realizing versatility and quick change, and reducing the amount of fixture adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

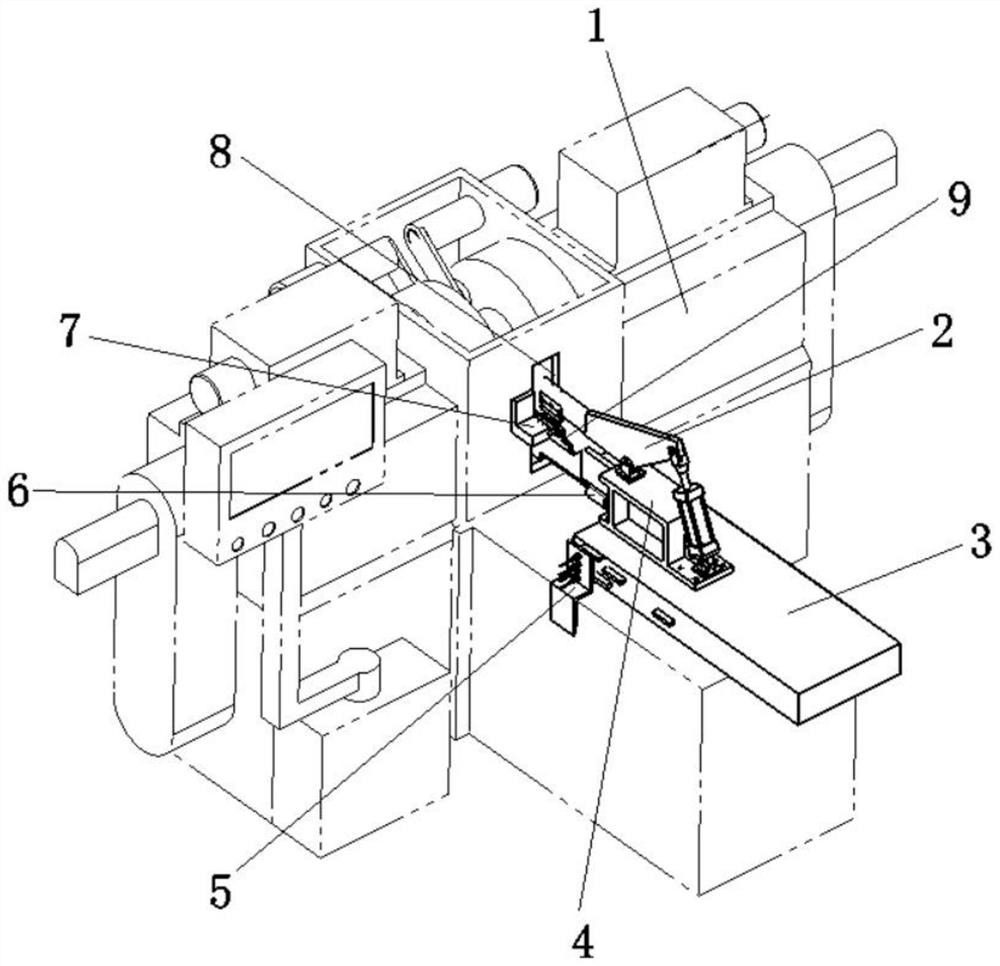

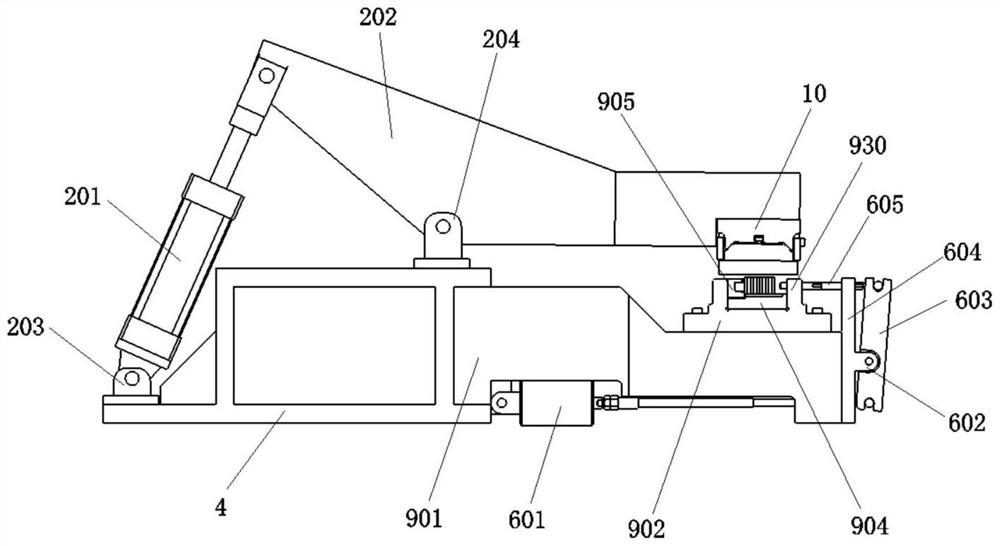

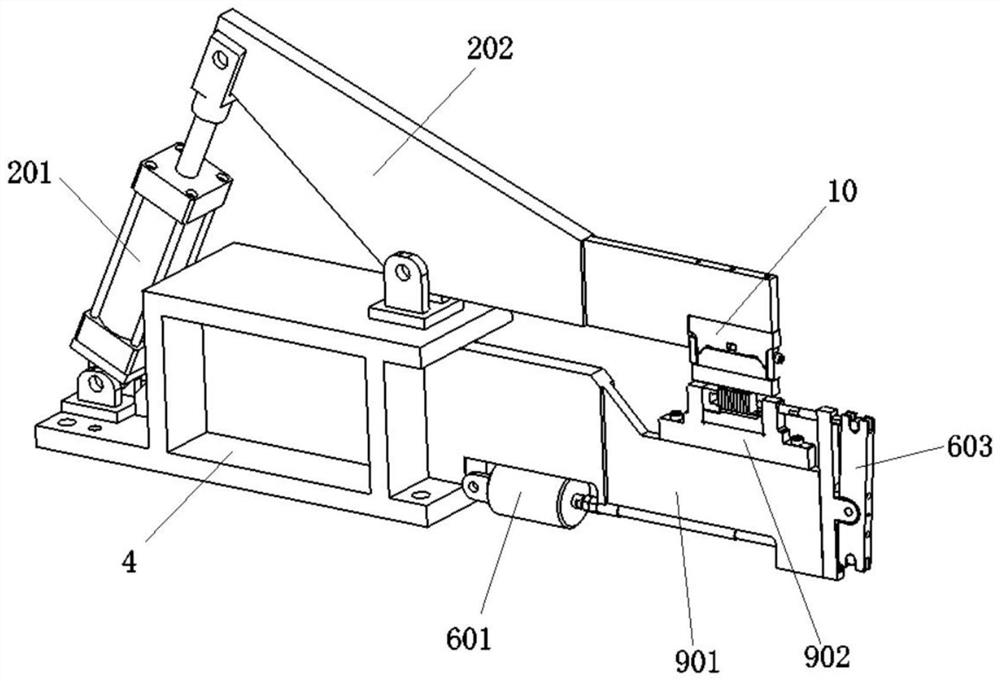

[0018] Embodiment of the present invention: a structural schematic diagram of a reciprocating grinding machine automatic feeding grinding fixture is as follows figure 1 As shown, including the existing reciprocating grinder 1, a hydraulic sliding table 3 is installed on the reciprocating grinding machine 1 and near the feeding port 8, a support seat 4 is fixedly installed on the hydraulic slide table 3, and a support seat 4 is fixed on the support seat 4. A feeding device 9 extending into the feeding port 8 is connected, and a floating pressing mechanism 2 and a top tightening mechanism 6 are respectively installed on the top and bottom of the feeding device 9, at the feeding port 8 and on one side of the feeding device 9 A side positioning block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com