Horizontal automatic filling device and method for large pressure-resistant structure model

A technology of automatic loading and pressure-resistant structure, which is applied in teaching models, infrastructure engineering, transportation and packaging, etc., can solve the problems that the pressure cylinder cannot be hoisted by a crane, the scale of the model is large, and the diameter of the opening is large, so as to achieve convenient docking, The effect of long transfer distance and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]DETAILED DESCRIPTION OF THE INVENTION The specific embodiments of the present invention will be described below.

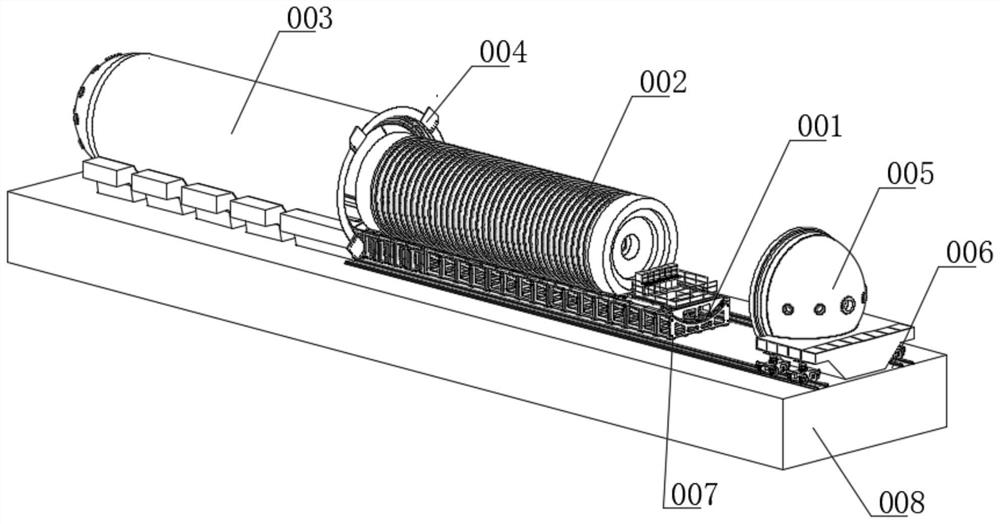

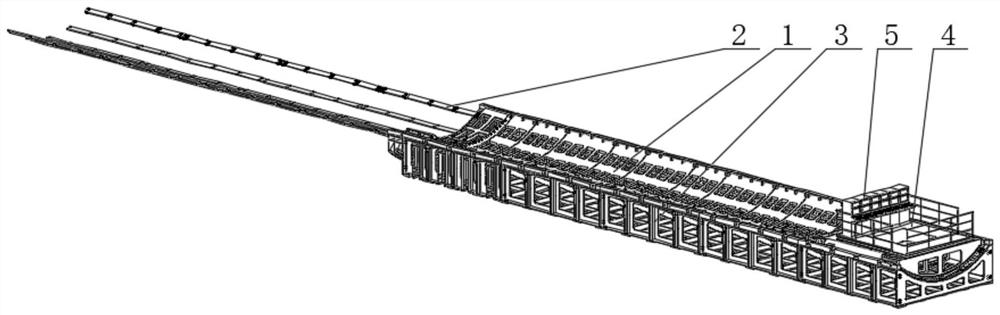

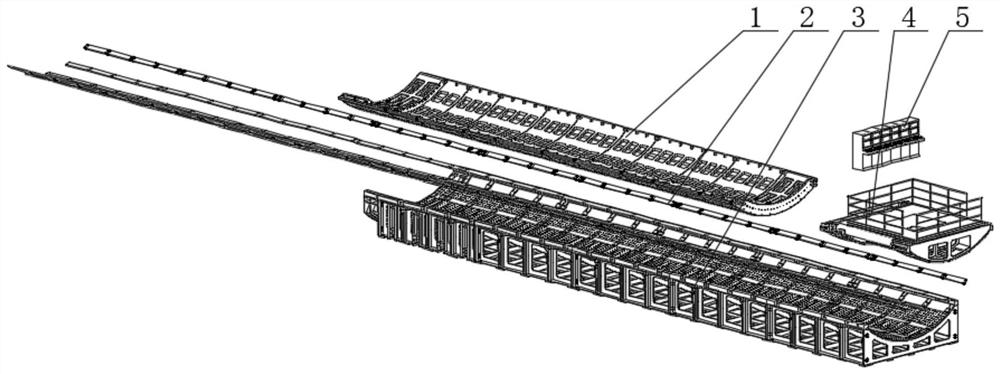

[0083]Such asFigure 1 - Figure 27As shown, the large-scale pressure-resistant structure model horizontal automatic filling device, including the device base 008, and the upper surface of the device base 008, there is a number of base pre-bolts 007, and the base prefraction plate 007 is passed. The fastener mounting the automatic filling device 001, the automatic filling device 001 is coupled to the horizontal pressure barrel 1003, and the automatic filling device 001 places the pressure-resistant structural model 002, the upper surface of the device base 008 is also installed by a sliding mechanism. Carriage 006, the cartridge carriage 006 is attached to the cartridge 005;

[0084]Also included, the clamp lattimeter 004, the clamp start mechanism 004 is mounted in the end of the horizontal pressure barrel 1003, the clamp start mechanism 004 controls the fitting of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com