Direct-acting automatic limiting device

A technology of automatic limit and limit device, applied in storage devices, transportation and packaging, etc., can solve the problems of low degree of automation, difficult maintenance and many supporting equipment, etc., to achieve high degree of automation, low use and maintenance costs, and simplification The effect of system composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

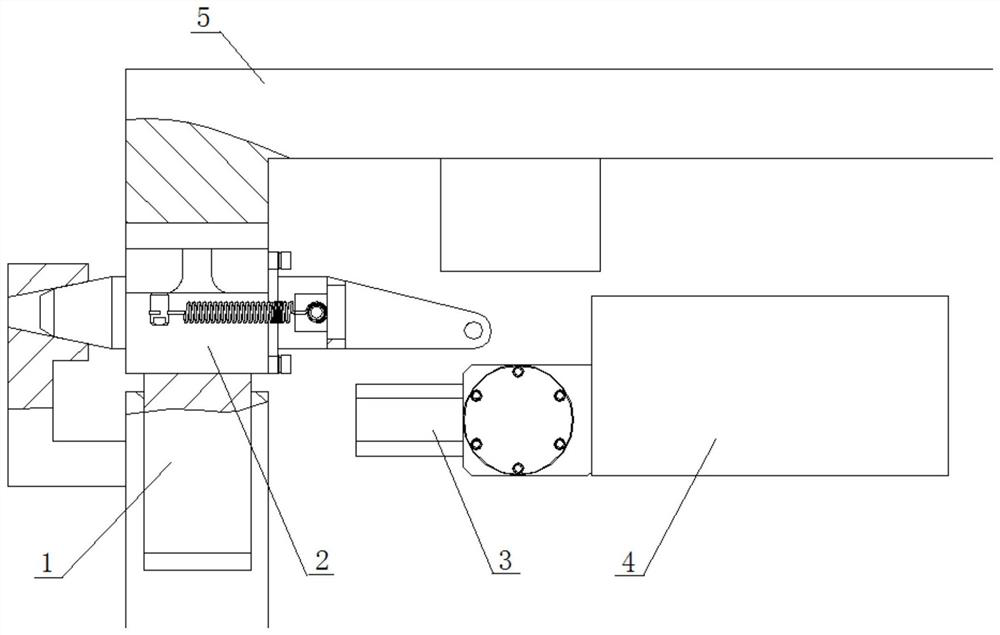

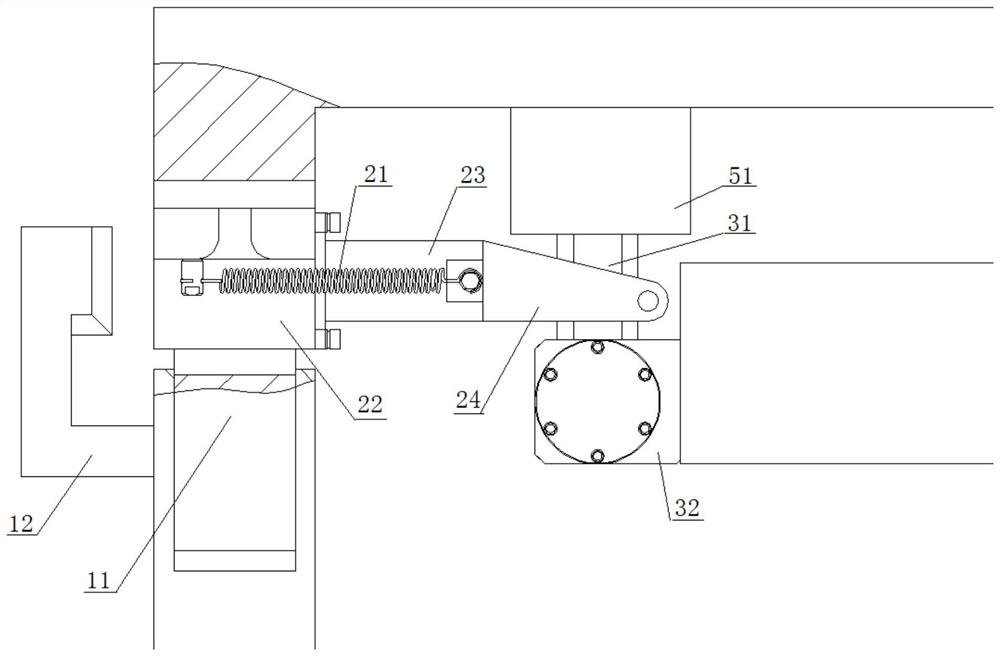

[0030] Such as Figure 1-3 As shown, the swing unlocking device 3 includes a swing shaft 31, a fixed seat 32 and a swing drive device 33, wherein the fixed seat 32 is arranged on the horizontal drive device 4, the swing drive device 33 is arranged on the fixed seat 32, and the output end is connected to the swing shaft 31 is vertically connected, and the swing shaft 31 is driven by the swing drive device 33 to swing, thereby pulling the linear motion limiter 2 to realize the unlocking of the tray 5 .

[0031] Further, the swing direction of the swing shaft 31 is perpendicular to the conveying direction of the storage roller table 1 .

[0032] In this embodiment, the swing driving device 33 is a servo motor, and the horizontal driving device 4 is a telescopic fork. The rollers 11 of the storage roller table 1 are used to carry the trays 5 .

[0033] The direct motion limiting device 2 includes a reset device 21, a guide fixing seat 22 and a limit pin 23, wherein the guide fix...

Embodiment 2

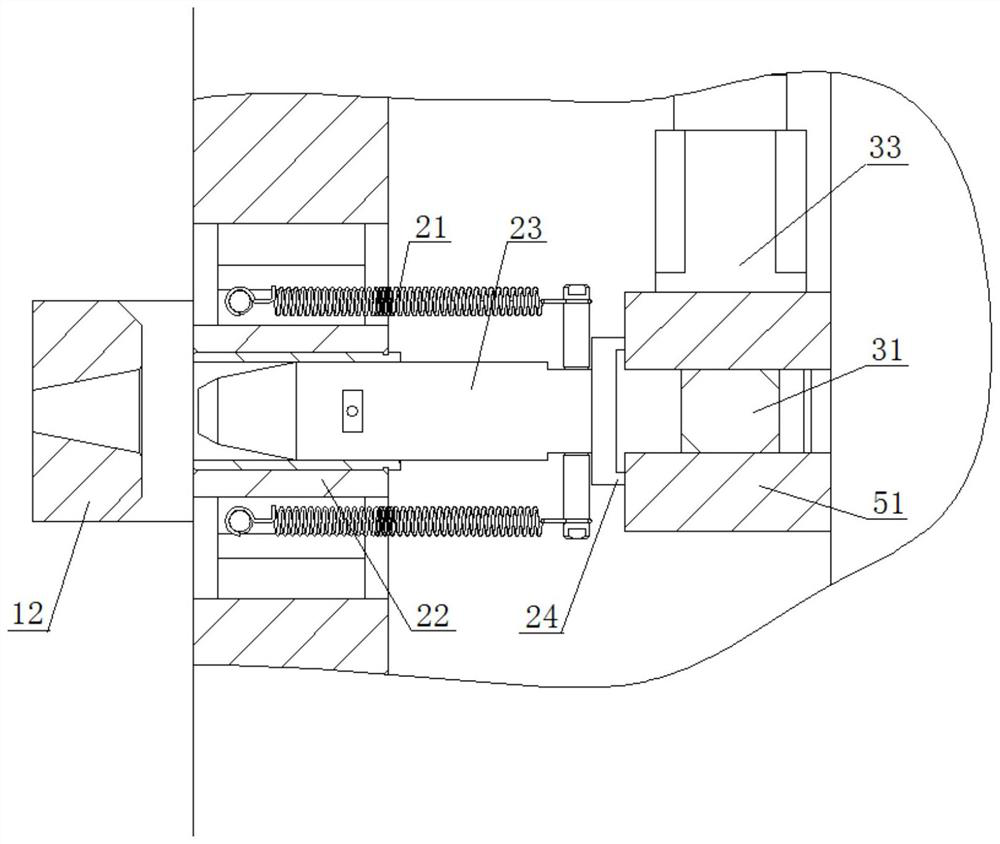

[0043] Such as Figure 4-6 As shown, the swing unlocking device 3 includes a swing shaft 31, a fixed seat 32 and a swing drive device 33, wherein the fixed seat 32 is arranged on the horizontal drive device 4, the swing drive device 33 is arranged on the fixed seat 32, and the output end is connected to the swing shaft 31 is vertically connected, and the swing shaft 31 is driven by the swing drive device 33 to swing, thereby pushing the linear motion limiter 2 to realize the unlocking of the tray 5 .

[0044] In this embodiment, the swing driving device 33 is a servo motor, and the horizontal driving device 4 is a telescopic fork. The rollers 11 of the storage roller table 1 are used to carry the trays 5 .

[0045]Straight motion limiter 2 comprises resetting device 21, guide fixed seat 22 and limit pin 23, wherein guide fixed seat 22 is arranged on the side of storage roller table 1, guide hole is offered along the vertical direction on guide fixed seat 22, limit position T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com