Automatic board clamping device and locating clamping method thereof

A splint and automatic technology, applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., can solve the problems of many parts of the width adjustment mechanism, easy to damage the substrate, etc., to ensure fast adjustment accuracy, reduce costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be further detailed in connection with the accompanying drawings:

[0044]The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings to better understand the scope of the invention in the art, whereby the advantages and characteristics of the present invention will be more clearly defined. The direction term mentioned in the present invention, for example, "on", "next", "before", "left", "right", "top", "bottom", etc., only refer to additional graphics direction. Therefore, the direction term used is used to illustrate and understand the invention, not to limit the invention.

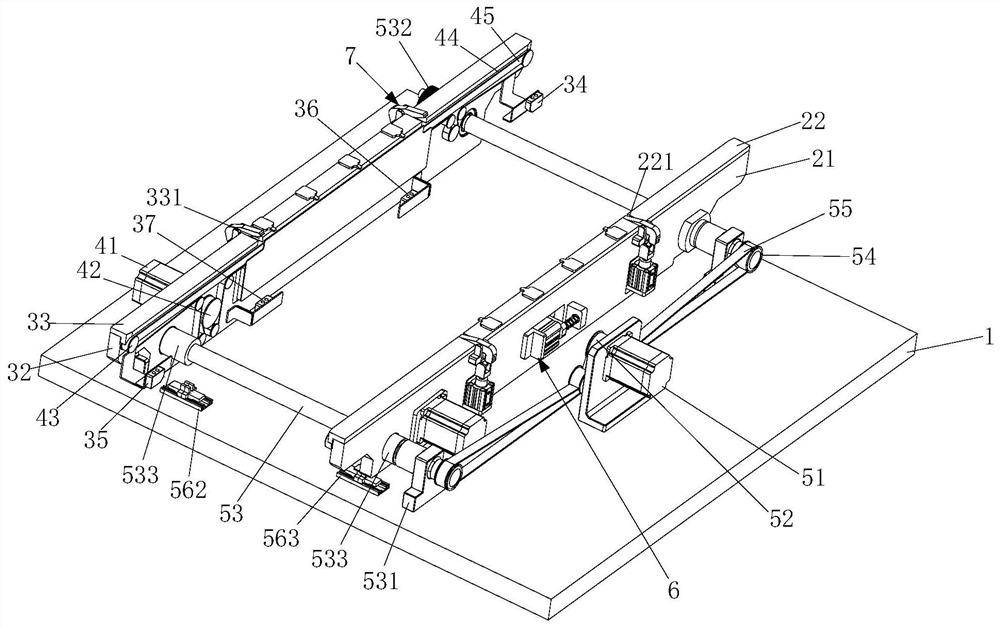

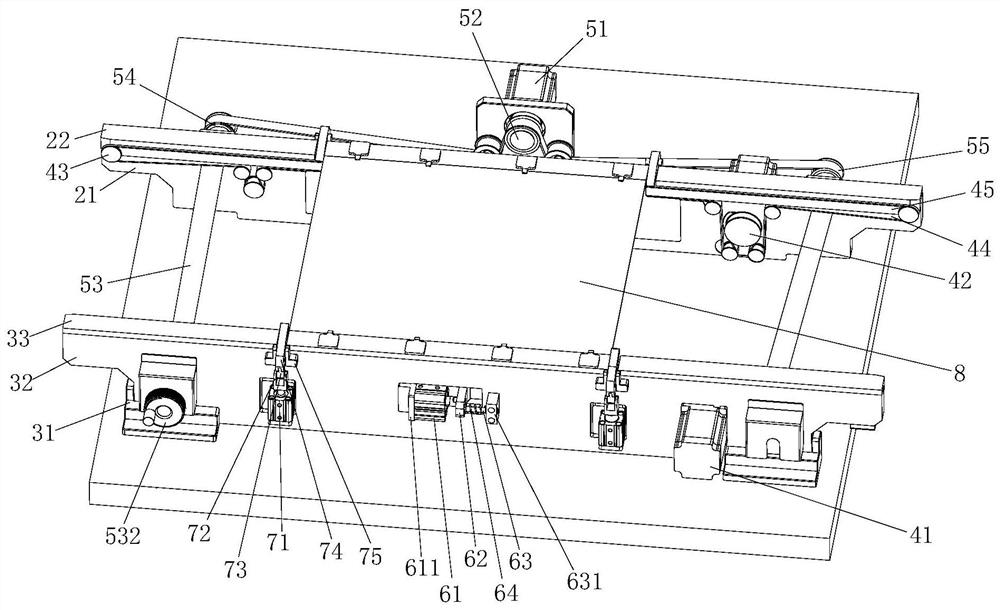

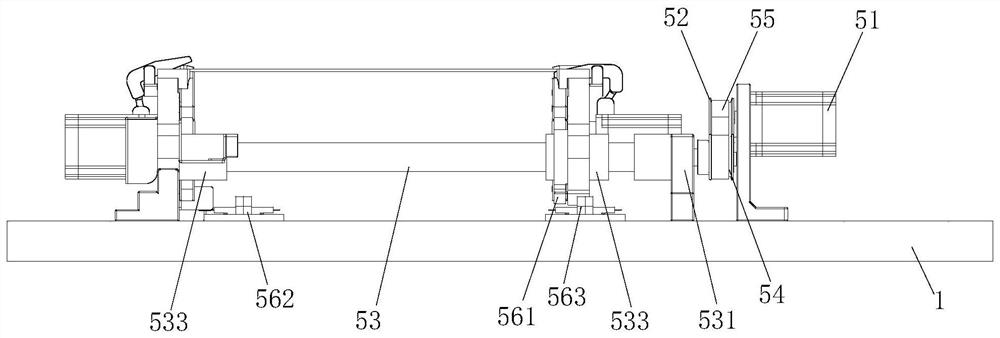

[0045]Seefigure 1 ,figure 2 As shown, an automatic splint device comprising a bottom plate 1, a movable track assembly 2, a fixed track assembly, a width adjustment mechanism 5, a control component, a control assembly, a control component, and an active rail assembly, a width adjustment mechanism 5, a control comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com