Organic working medium expansion machine rotor

An expander and working medium technology, applied in the field of expanders, can solve problems such as abnormal axial force, low efficiency, and poor working conditions of expander rotors, and achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

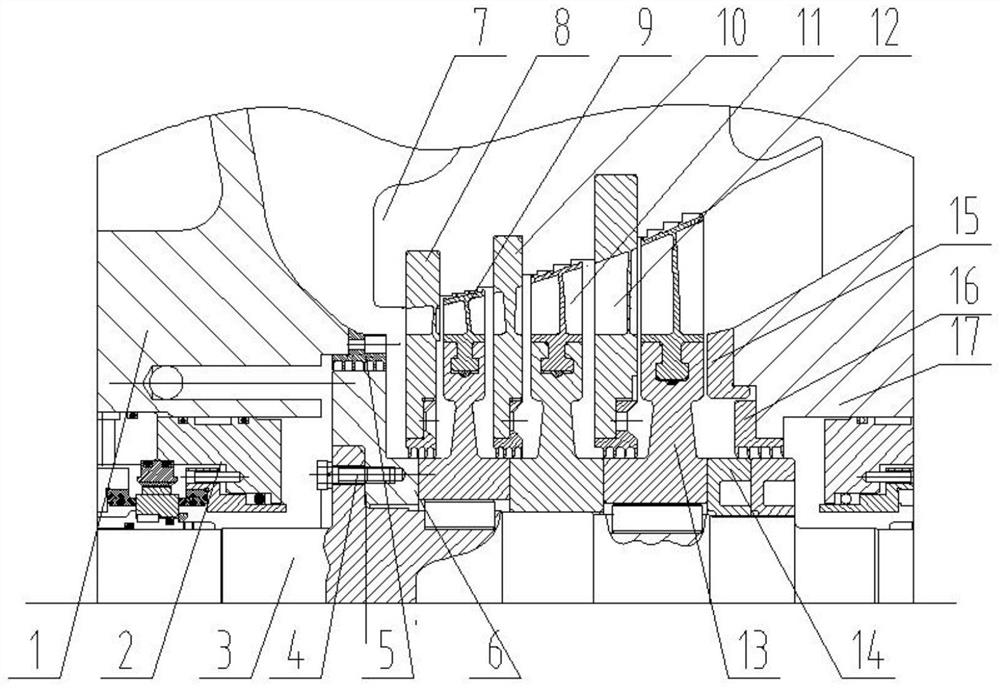

[0030] Such as figure 1 As shown, an expander axial force stabilization system, mechanical seal 2, balance air seal 5, nozzle ring seat 7 installed on the intake shell 1, balance plate bolt 4, balance plate 6, first stage turbine 9, secondary Turbine 11, last stage turbine 13, main shaft nut 14 installed on the main shaft, 5 outlet guide, final air seal 16 installed on exhaust shell 17; first stage nozzle ring 8, secondary nozzle ring 10, final stage nozzle ring 12 is installed on the nozzle ring seat 7.

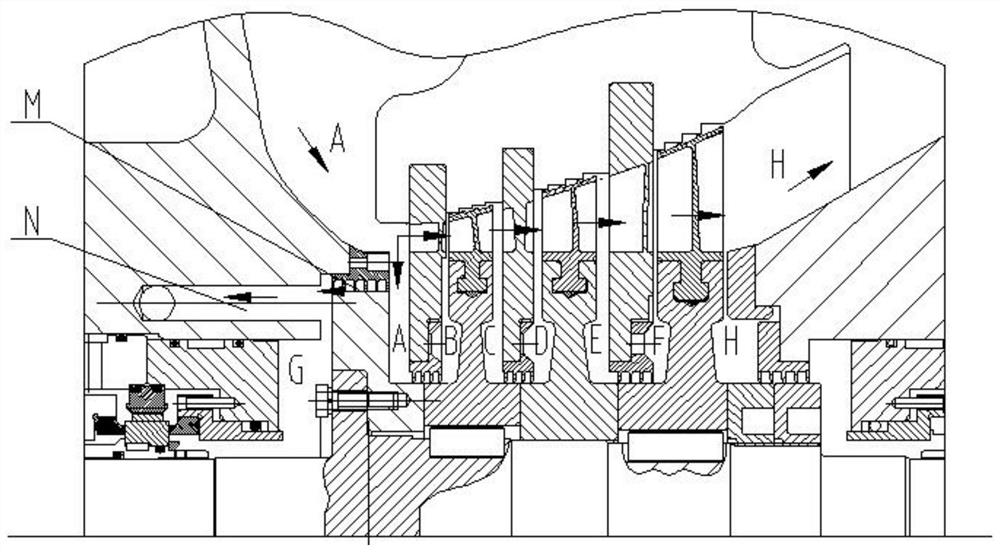

[0031] combine figure 1 see figure 2 , air inlet shell 1, nozzle ring seat 7, first stage nozzle ring 8, balance air seal 5, balance plate 6 separates chamber A, chamber internal static pressure PA; nozzle ring seat 7 first stage nozzle ring 8 first stage turbine 9 Separate chamber B, static pressure PB in the chamber; nozzle ring seat 7, primary turbine 9, secondary nozzle ring 10 separate chamber C, chamber static pressure PC; nozzle ring seat 7, secondary nozzle ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com