Rotary cylinder piston compressor

A compressor and rotary cylinder technology, applied in the field of compressors, can solve the problems of large piston force, many wearing parts, large friction surface, etc., and achieve the effects of improving performance, reducing leakage, and reducing relative clearance volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. The following description of at least one embodiment is merely illustrative in nature and in no way is taken as any limitation of the invention and its application or uses. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

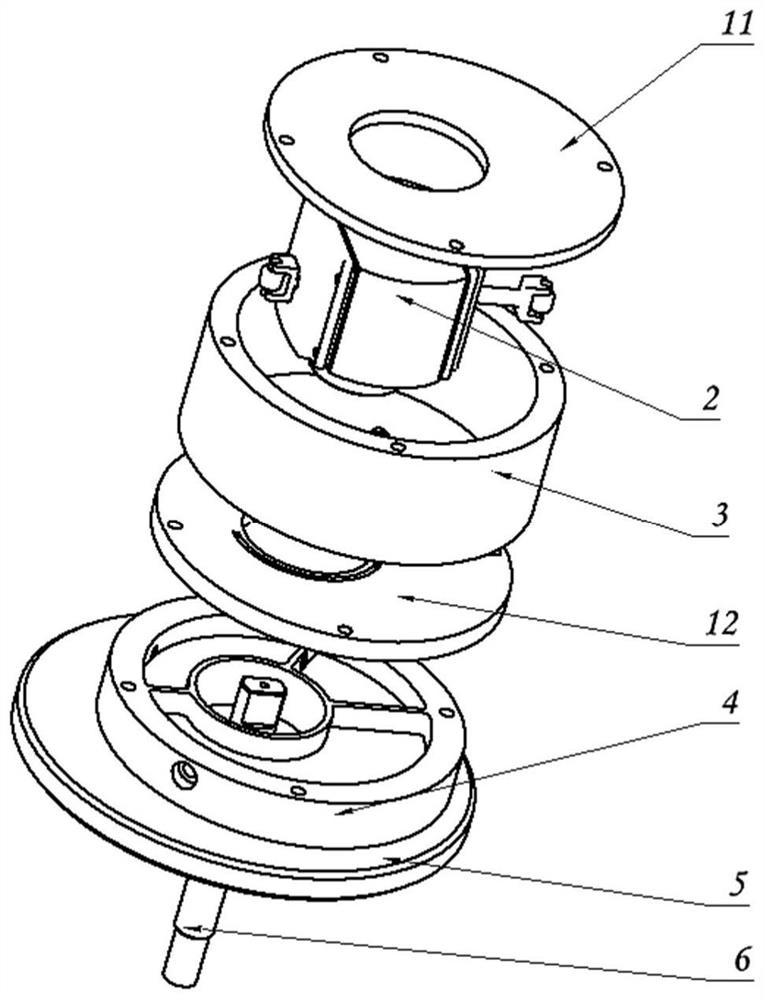

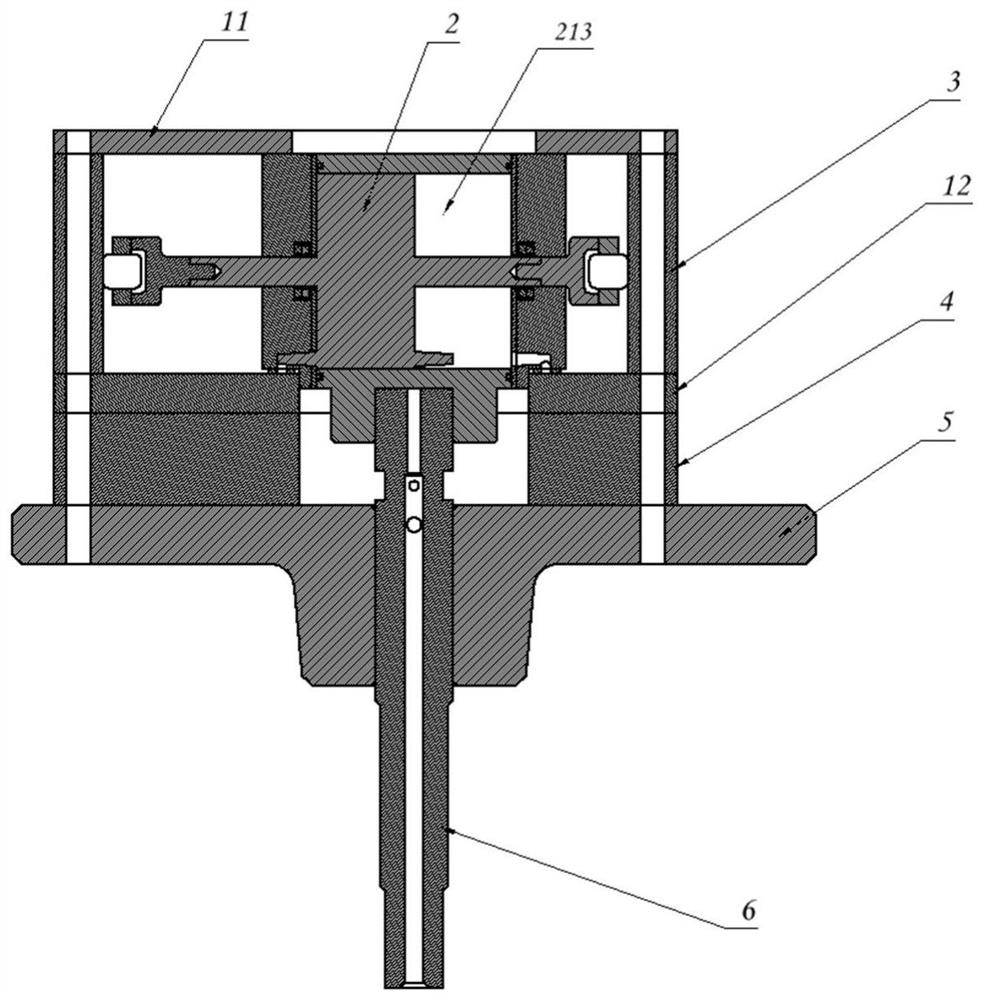

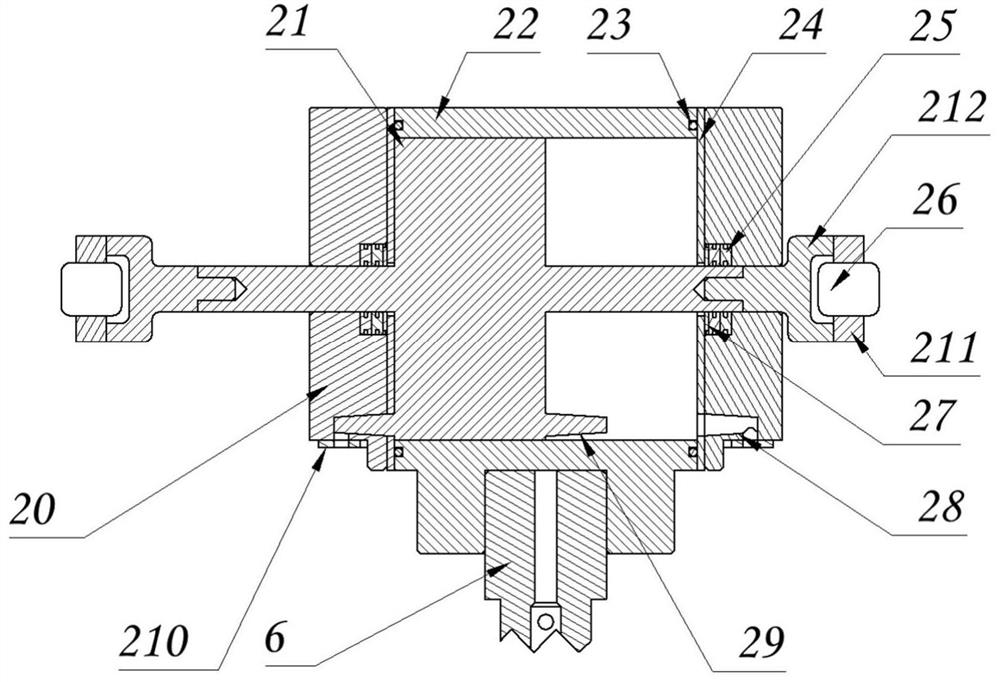

[0038] A rotary cylinder piston compressor, including an upper support plate 11, a valve plate 12, a rotating part 2, a cylinder liner 3, a valve cover 4 and a rotating shaft 6, wherein the rotating part 2 includes a piston connecting rod 21, a rotating cylinder 22, and a sealing ring 23 , Baffle 24, reciprocating sealing ring 25, needle roller bearing 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com