Crosslinked cable butt joint auxiliary device

An auxiliary device, a technology for cross-linked cables, applied in the direction of equipment for connecting/terminating cables, etc., can solve problems such as low accuracy, and achieve the effect of reducing labor intensity, easy to move and fix, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

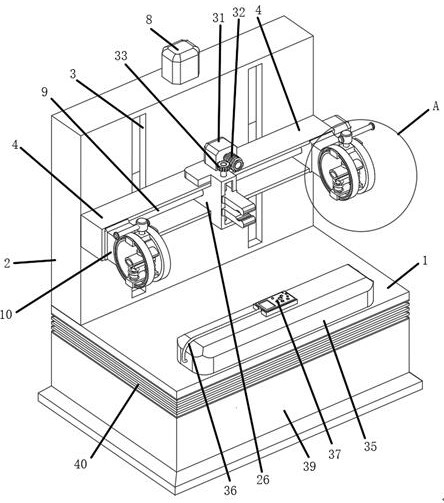

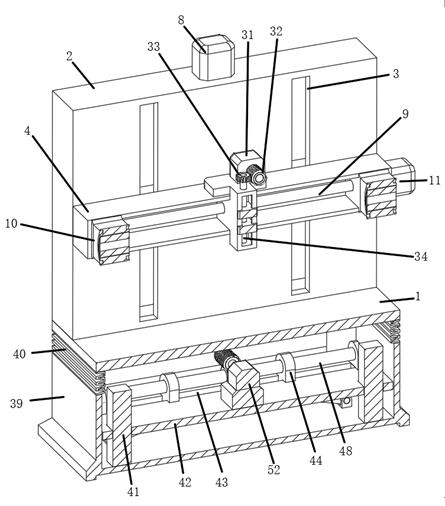

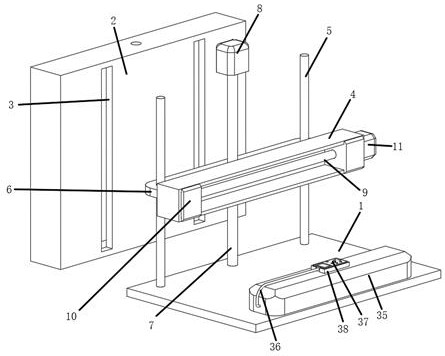

[0026] refer to Figure 1-7 , a cross-linked cable docking auxiliary device, including a workbench 1, one side of the upper surface of the workbench 1 is fixed with a lifting installation box 2, and one side of the lifting installation box 2 is provided with two elongated through chutes 3, two The inner wall sliding connection of two elongated through chute 3 is provided with transverse installation seat 4, and lifting installation box 2 is fixedly provided with the lifting assembly that makes transverse installation seat 4 produce displacement, and the inner wall rotation connection of transverse installation seat 4 is provided with the first double screw thread The screw mandrel 9 and the inner wall of the transverse mounting seat 4 are symmetrically slidably connected to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com