A stapler with the function of a dual-motor drive mechanism

A dual-motor-driven, stapler technology, applied in the field of staplers, can solve the problems of inconvenient operation, poor grip, and long time consumption, and achieve the effects of convenient and fast operation, good clamping effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

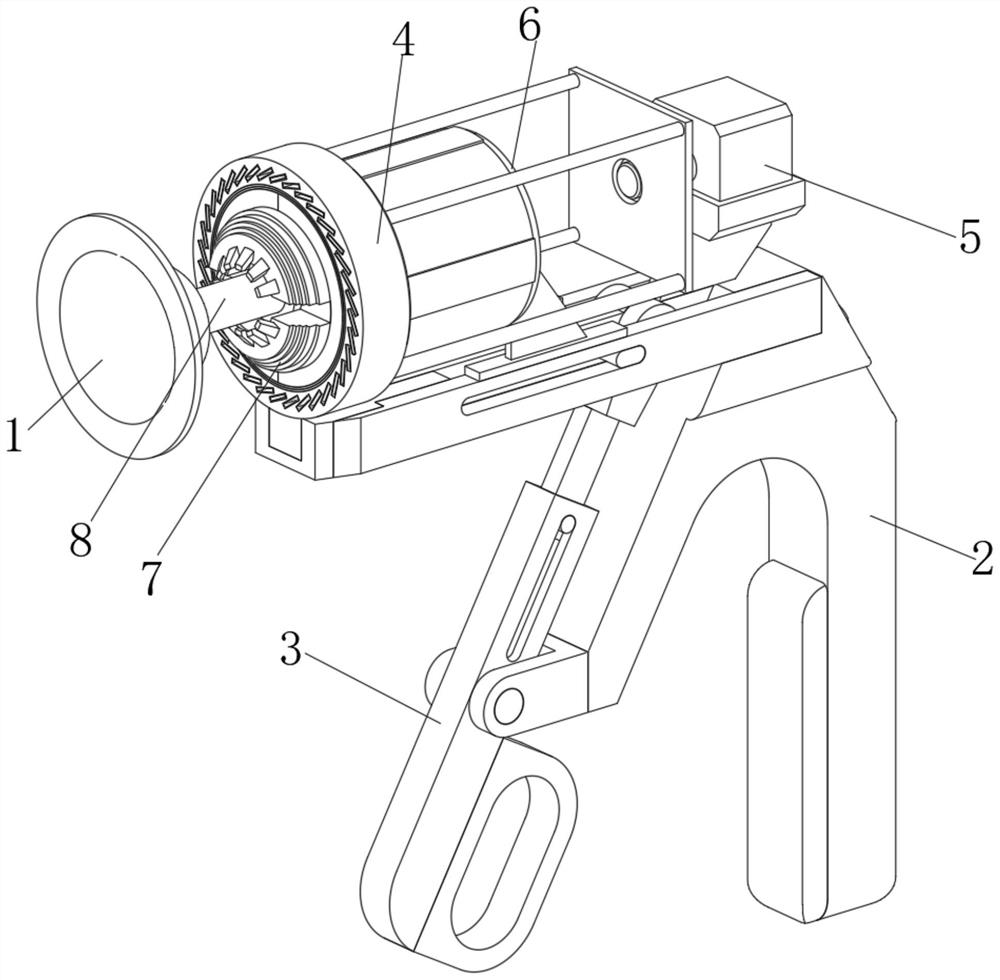

[0038] A stapler with the function of a dual-motor drive mechanism, such as Figure 1-3 As shown, it includes a support mechanism 2, the support mechanism 2 is gun-shaped, a manual drive mechanism 3 is movably connected to the support mechanism 2, and the upper rear part of the manual drive mechanism 3 passes through the upper end surface of the support mechanism 2 and is fixedly connected with an external drive mechanism 5. An anastomotic cutting and suturing mechanism 4 is fixedly connected to the front of the upper end of the manual driving mechanism 3. The anastomotic cutting and suturing mechanism 4 has a ring structure. The inner circumference surface of the protective shell 6 is movably connected with two protective shells 6, and the two protective shells 6 are distributed symmetrically on the left and right. The two protective shells 6 together form a cylinder, and the inner front sides of the two protective shells 6 A connecting mechanism 8 is fixedly connected, and t...

Embodiment 2

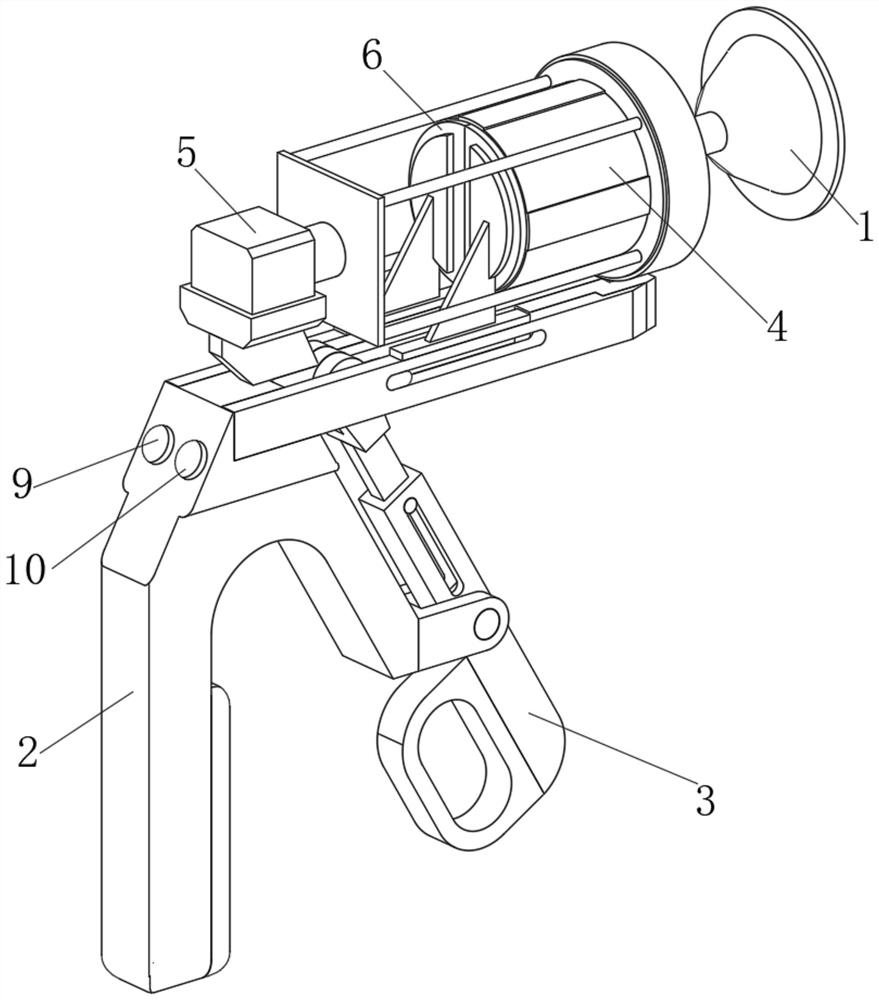

[0042] On the basis of Example 1, as Figure 3-7 As shown, a stapler with the function of a dual-motor drive mechanism includes a support mechanism 2, the support mechanism 2 is gun-shaped, and a manual drive mechanism 3 is movably connected to the support mechanism 2, and the rear part of the upper end of the manual drive mechanism 3 passes through the support The upper end surface of the mechanism 2 is fixedly connected with an external driving mechanism 5, and the upper front part of the manual driving mechanism 3 is fixedly connected with an anastomosis cutting and suturing mechanism 4. The front end face of the driving mechanism 3 is movably connected with a protective shell 6 on the inner peripheral surface of the anastomosis cutting and suturing mechanism 4, and there are two protective shells 6, and the two protective shells 6 are symmetrically distributed on the left and right, and the two protective shells 6 together form a Cylinder, the inner front side of the two p...

Embodiment 3

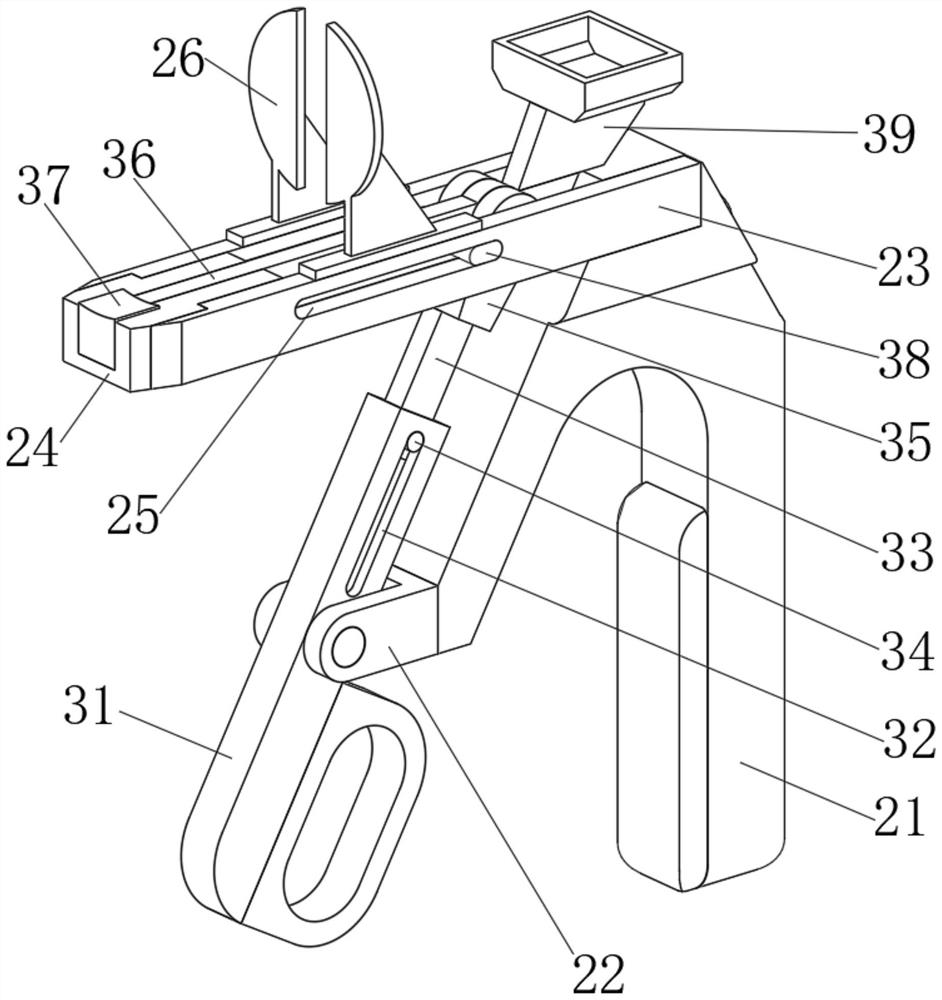

[0049] On the basis of Example 1, as Figure 8-10 As shown, a stapler with the function of a dual-motor drive mechanism includes a support mechanism 2, the support mechanism 2 is gun-shaped, and a manual drive mechanism 3 is movably connected to the support mechanism 2, and the rear part of the upper end of the manual drive mechanism 3 passes through the support The upper end surface of the mechanism 2 is fixedly connected with an external driving mechanism 5, and the upper front part of the manual driving mechanism 3 is fixedly connected with an anastomosis cutting and suturing mechanism 4. The front end face of the driving mechanism 3 is movably connected with a protective shell 6 on the inner peripheral surface of the anastomosis cutting and suturing mechanism 4, and there are two protective shells 6, and the two protective shells 6 are symmetrically distributed on the left and right, and the two protective shells 6 together form a Cylinder, the inner front side of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com