Large-scale electrical upsetting method and anvil electrode for gradient change of electrode resistivity

A gradient change, electrode resistance technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., to prevent central depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

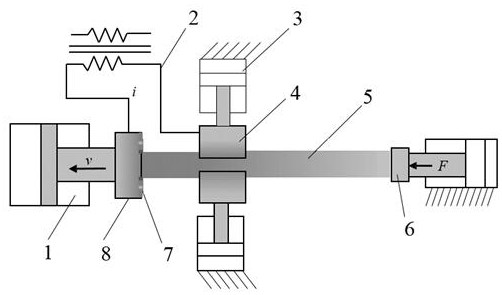

[0029] refer to figure 2 As shown, 1 is the anvil cylinder, 2 is the secondary transformer, 3 is the clamping cylinder, 4 is the clamping electrode, 5 is the rod blank, 6 is the anvil of the upsetting cylinder, 7 is the annular belt coating, and 8 is the anvil electrode.

[0030] A large-scale electric upsetting method for electrode resistivity gradient change, comprising the following steps:

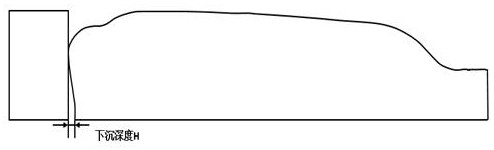

[0031] Under the action of electric upsetting, the rod blank 5 gradually increases radially to form garlic;

[0032] When the garlic radially increases to the point where the center of the garlic is separated from the anvil electrode, the ring zone where the anvil electrode is in contact with the edge of the garlic is used as the ring-shaped suppression zone on the anvil electrode (when the outer ring area is not set);

[0033] increasing resistivity across said annular zone of inhibition to locally reduce current density;

[0034] During the radial increase of the garlic head, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com