Convenient edge grinding equipment for organic wood-like floor

A technology for wood-like flooring and edging equipment, applied in portable grinding machines, grinding/polishing equipment, metal processing equipment, etc., which can solve the problems of high production process costs, poor portability, and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

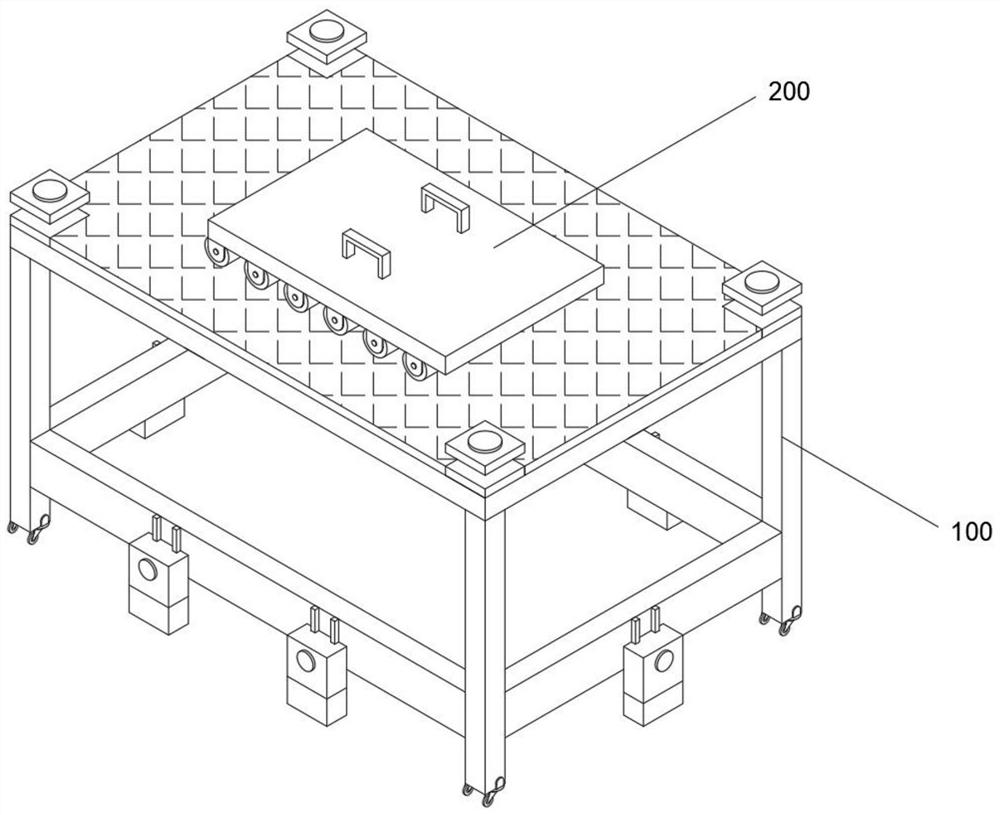

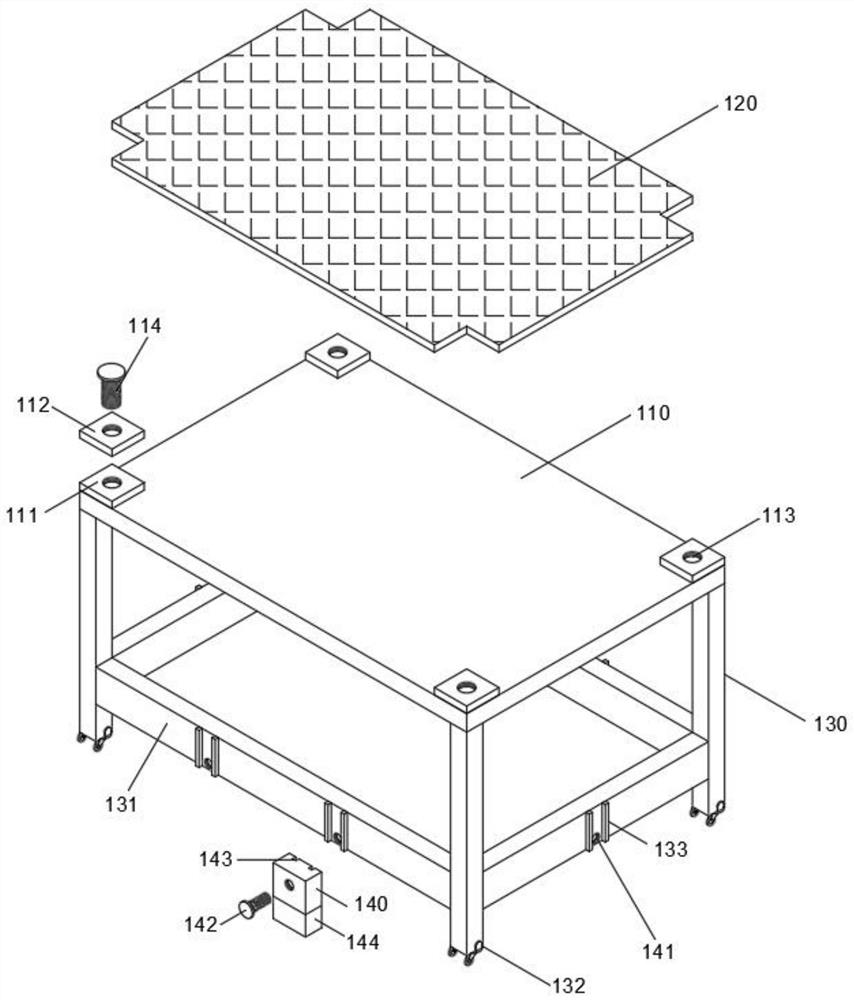

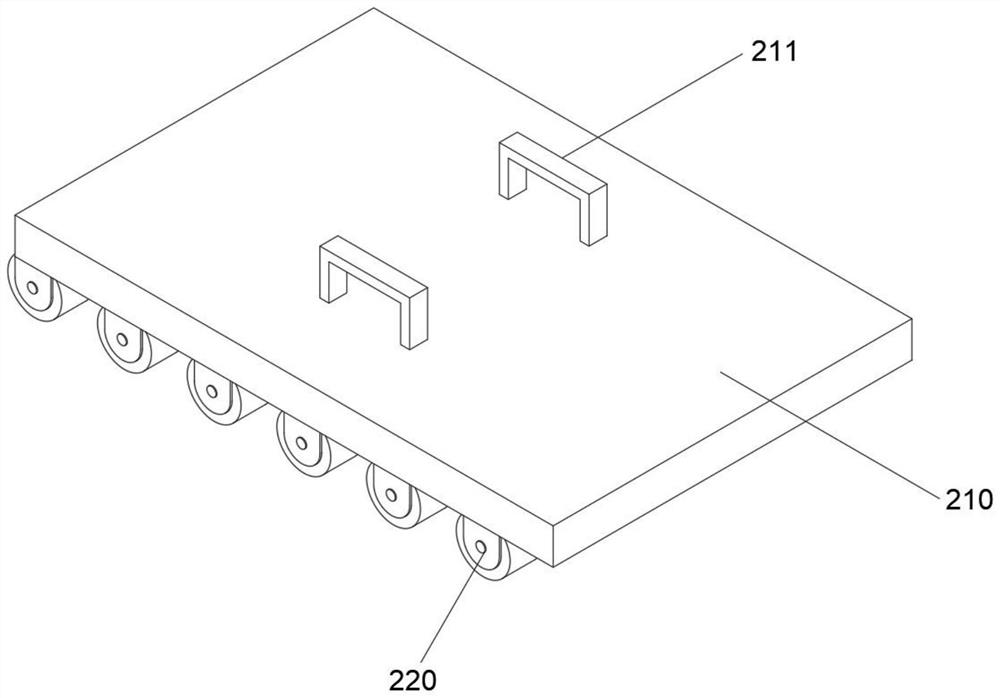

[0030] see Figure 1-Figure 4 As shown, the present embodiment provides a portable edging device for an organic imitation wood floor, including a support device 100, an edging device 200 installed on the upper side of the support device 100, the support device 100 includes a support base 110, and on the support base 110 The lower limit block 111 is installed at the four corners of the surface, and the upper limit block 112 is installed on the upper side of the lower limit block 111. The lower limit block 111 and the upper limit block 112 surface are provided with a limit hole 113, and the limit hole 113 has a built-in limit bolt 114. The threaded connection of the limit bolt 114 and the limit hole 113 fixes the floor between the upper limit block 112 and the lower limit block 111, which facilitates better edging processing. The edging device 200 includes a square plate 210, and the bottom plate 210 A number of grinding roller devices 220 are installed on the surface, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com