Shoe sole and manufacturing method thereof

A manufacturing method and technology for shoes, applied in the direction of soles, footwear, reinforcements, etc., can solve problems such as unreliable firmness, separation of cloth layers, and unfashionable appearance, so as to improve aesthetics, enhance air permeability, and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

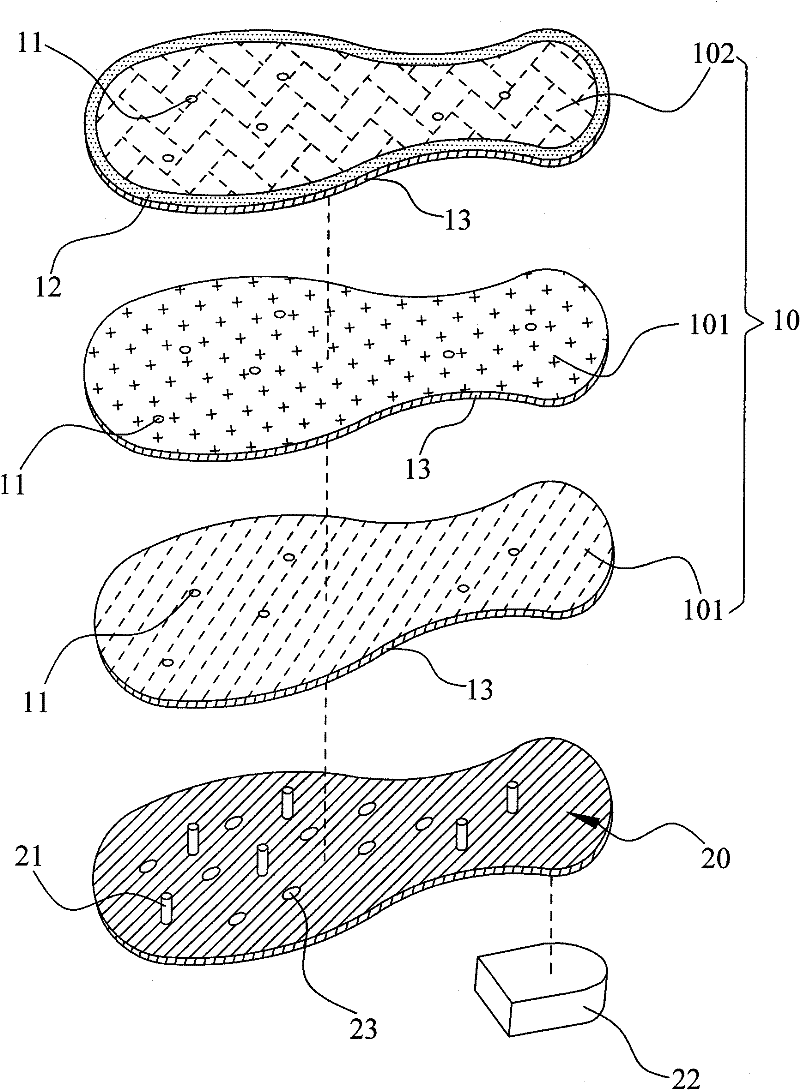

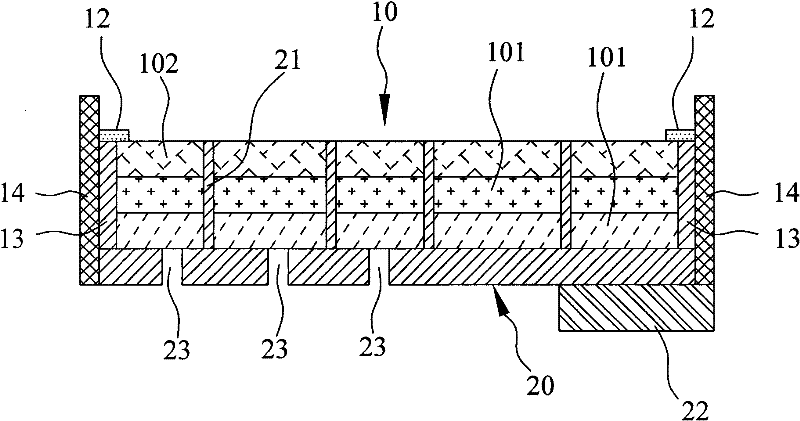

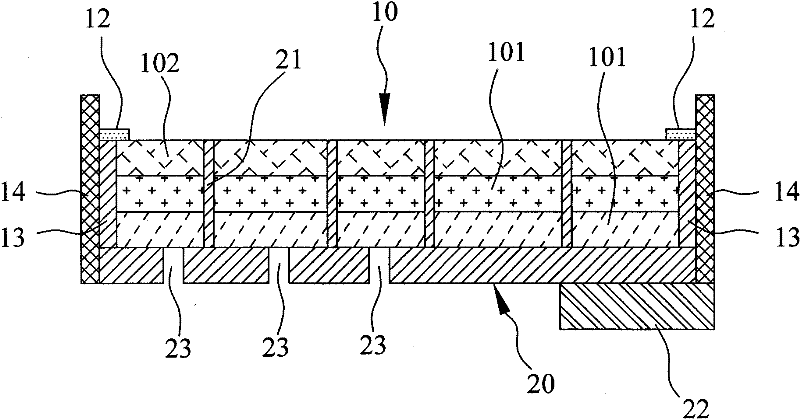

[0038] Please refer to figure 1 and figure 2 Shown, it has shown the concrete structure of preferred embodiment of the present invention, a kind of sole, comprises the cloth layer bottom 10 and the outsole 20 of shoe that are superimposed up and down, wherein:

[0039] The cloth layer bottom 10 is provided with a plurality of punching holes 11 that run through the upper and lower surfaces of the cloth layer bottom 10. The cloth layer bottom 10 includes a plurality of cloth layers 101, at least one of which is soaked in a medicinal solution that has a health care effect. Health-care layer 102, to prevent the generation of foot disease, present embodiment this cloth layer bottom 10 comprises three cloth layers 101, and wherein uppermost cloth layer 101 is health-care layer 102, in order to directly contact with people's soles, but not To limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com