Storage and handling integrated device for plate machining

A sheet metal processing and integrated technology, applied in the field of sheet metal processing, can solve the problems of bulky metal sheets and labor-intensive, etc., and achieve the effects of avoiding excessive extrusion force, improving stability, and avoiding bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

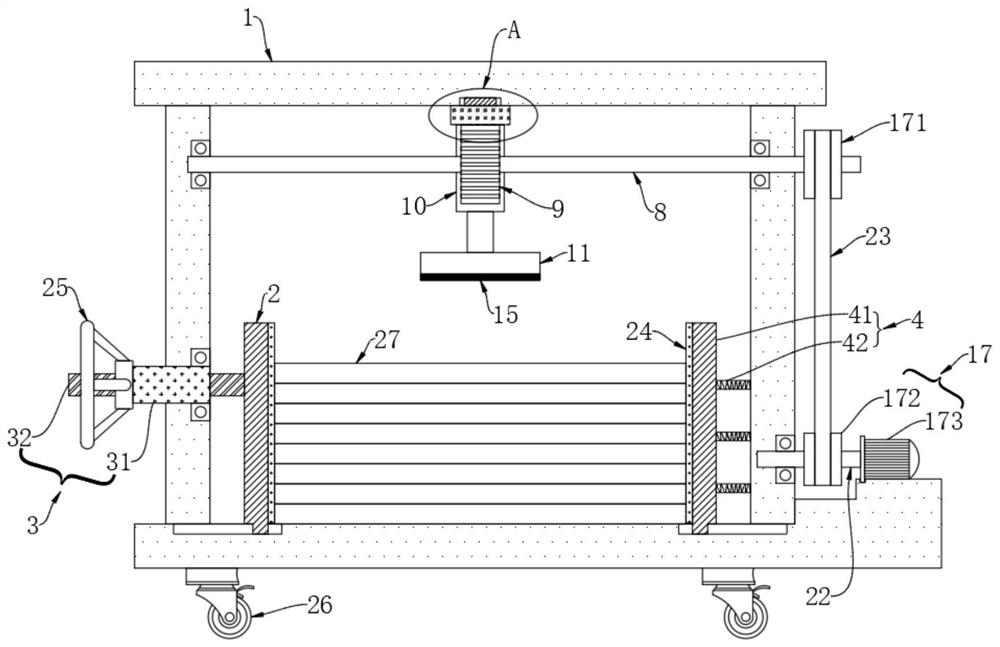

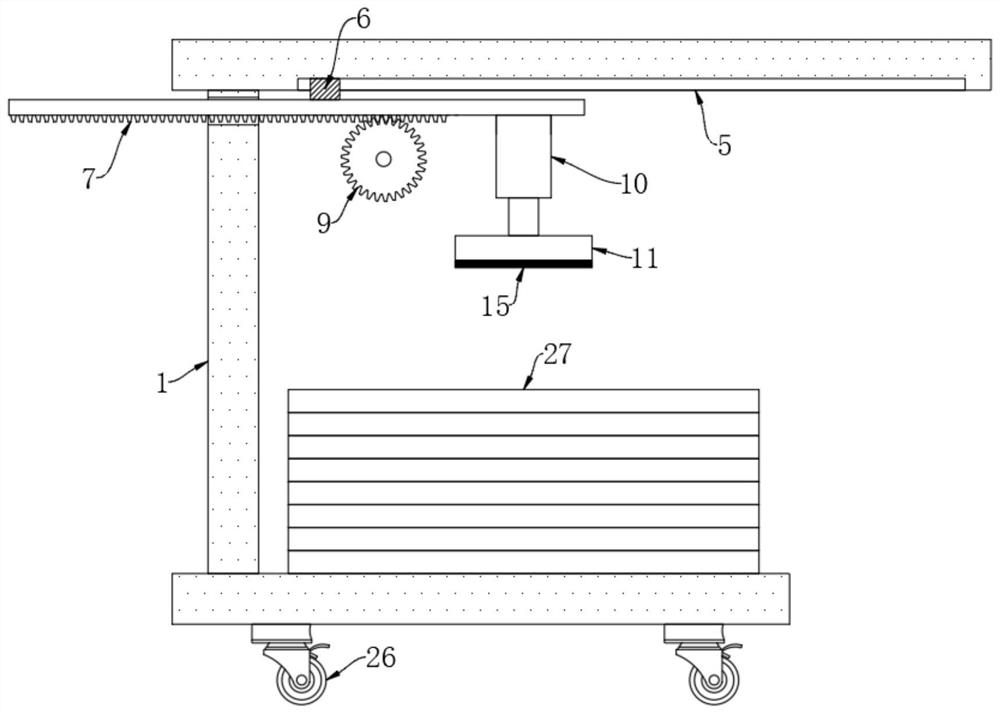

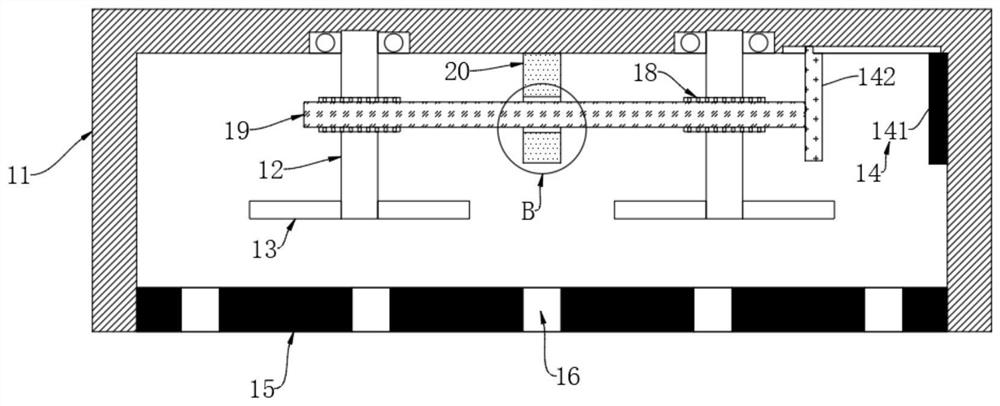

[0032]Such asFigure 1-5As shown, a sheet processing is stored and handled, including storage frame 1, and a plurality of universal wheel 26, and a universal wheel 26 self-locking, and universal wheel 26. It is convenient for the user to move the entire device, and the storage frame 1 slides on the connection plate 2, and the stabilizing mechanism 3 in which the cassette 1 is disposed, the stabilizing mechanism 3 includes a threaded sleeve 31 and a screw 32, a thread sleeve 31 Turn on the storage frame 1, the screw 32 is threaded into the thread sleeve 31, and one end of the screw 32 is fixedly coupled to the plate 2, by the set thread sleeve 31 and the screw 32, can regulate the plate 2 movement, so that The plate 2 can be adjusted to the storage of the iron plate 27, thereby increasing the stability of the placement of the iron plate 27, the threaded angle of the screw 32 is smaller than the friction angle between the screw 32 and the threaded sleeve 31, the threaded angle design o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com