Novel hollow tire

A new type of tire technology, applied in the direction of non-pneumatic tires, tire parts, tire tread/tread pattern, etc., can solve the problems of affecting the use of users, sand entering, affecting the shock absorption effect and service life, etc., to increase The effect of service life, ease of rotation, reduction of material cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012]The present invention will be further described with reference to the specific embodiments.

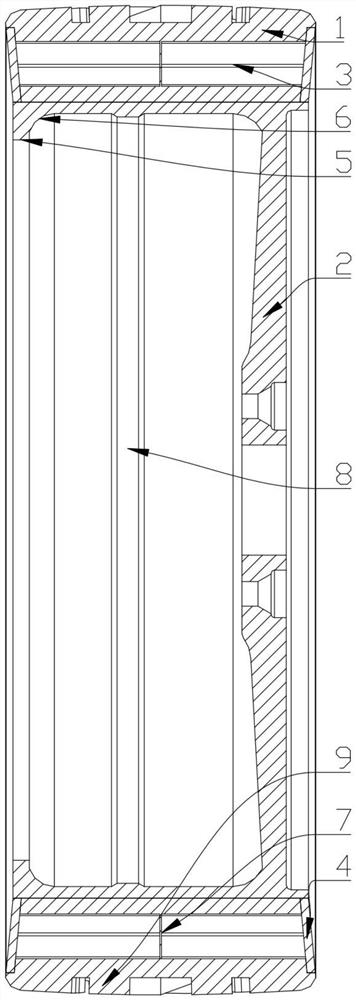

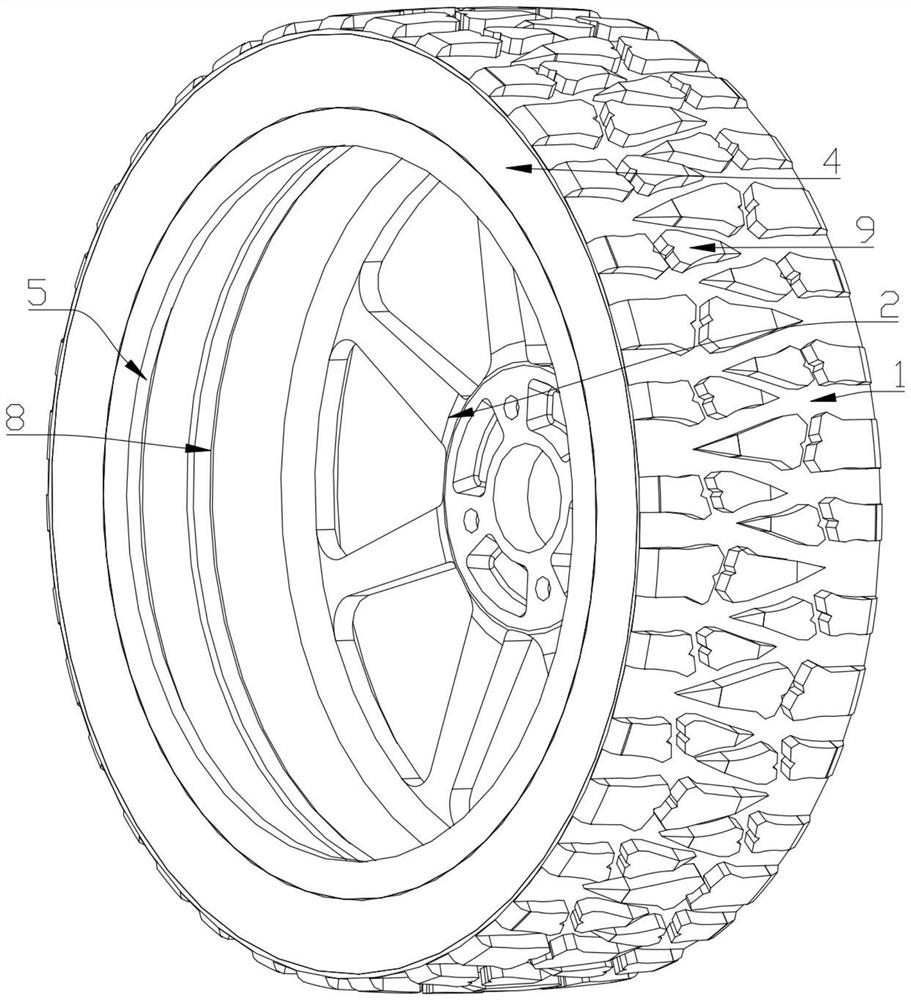

[0013]Such asFigure 1-2As shown, a new hollow tire comprises a tire 1 and a hub 2, the tire 1 and the hub 2 primary sulfide is integrated, and the tire 1 side is opened along the circumference, and the hollow portion 3 is opened. On the side, a cover layer 4 is provided, the cover layer 4 is covered with a tire 1 secondary molding; the hub 2 has a first reinforcing rib 5, the first reinforcing rib 5 and the hub 2 inner wall through an arc. 6 transition.

[0014]The stepping wafer of the present technology is stabilized on both sides, which greatly reduces the wind noise in which the wind enters into the hollow portion 3 is used, and the weight of the body is extruded in the body, which can make The tire has good elastic, easy to rotate, and the cover layer 4 can be placed in the hollow portion 3, increasing the life of the tire, and the opening of the hollow portion 3 is greatly reduced by ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap