Composite rubber and preparation method thereof and sole material

A compound rubber and rubber technology, applied in the field of materials, can solve the problems of wear resistance decline and achieve excellent wet slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a preparation method of the composite rubber, comprising: mixing foamed rubber particles with non-foamed rubber particles, molding and vulcanizing to obtain composite rubber.

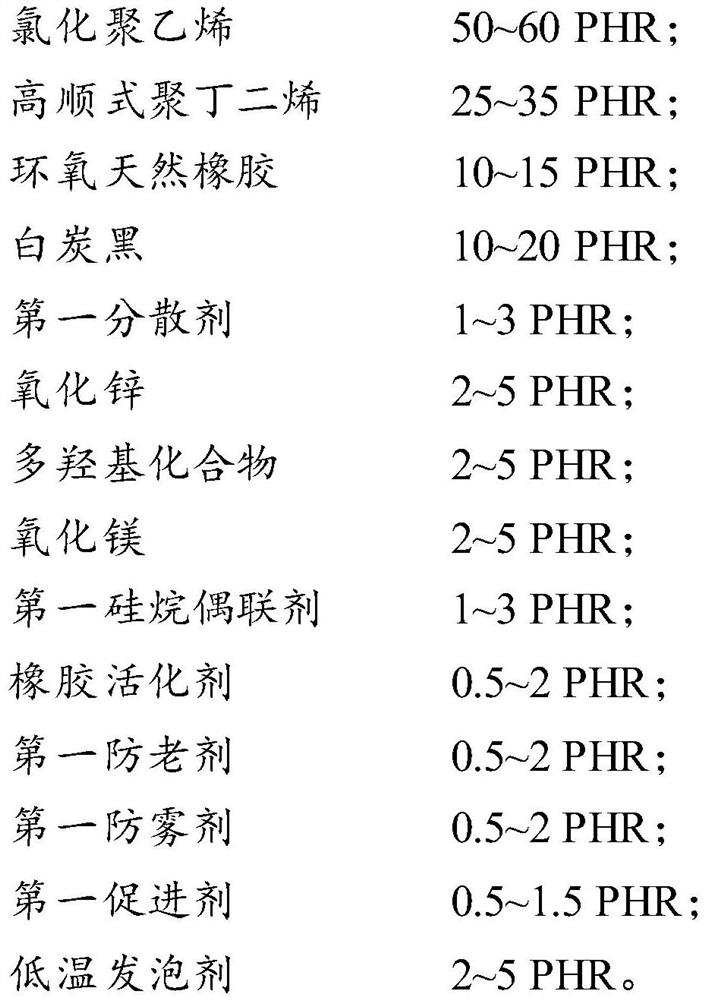

[0063] The foamed rubber particles are prepared according to the following method: 50-60 PHR of chlorinated polyethylene, 25-35 PHR of high-cis polybutadiene, 10-15 PHR of epoxy natural rubber, 10-20 PHR of white carbon black, 1-20 PHR of the first dispersant 3PHR; zinc oxide 2~5PHR, polyol 2~5PHR; magnesium oxide 2~5PHR; first silane coupling agent 1~3PHR, rubber activator 0.5~2PHR, first antiaging agent 0.5~2PHR, first anti-fog 0.5-2PHR of the agent, 0.5-1.5PHR of the first accelerator and 2-5PHR of the low-temperature foaming agent are mixed, molded and foamed to obtain foamed rubber particles.

[0064] Among them, the chlorinated polyethylene, high cis polybutadiene, epoxy natural rubber, white carbon black, the first dispersant, zinc oxide, polyol, magnesi...

Embodiment 1

[0073] Foam rubber raw material:

[0074]

[0075]

[0076] Mix the raw materials of the above-mentioned foam rubber at 165°C and 150kg / cm 2 Molding and foaming for 270s to obtain foamed rubber particles.

[0077] Non-foaming rubber raw material

[0078]

[0079] Mix the above non-foaming rubber raw materials at 165°C, 150kg / cm 2 Molded for 270s to obtain non-foaming rubber particles.

[0080] Mix foamed rubber particles (blue) and non-foamed rubber particles (red) according to the mass ratio of 30:70, 160°C, 150kg / cm 2 Forming and vulcanizing for 270s to obtain composite rubber.

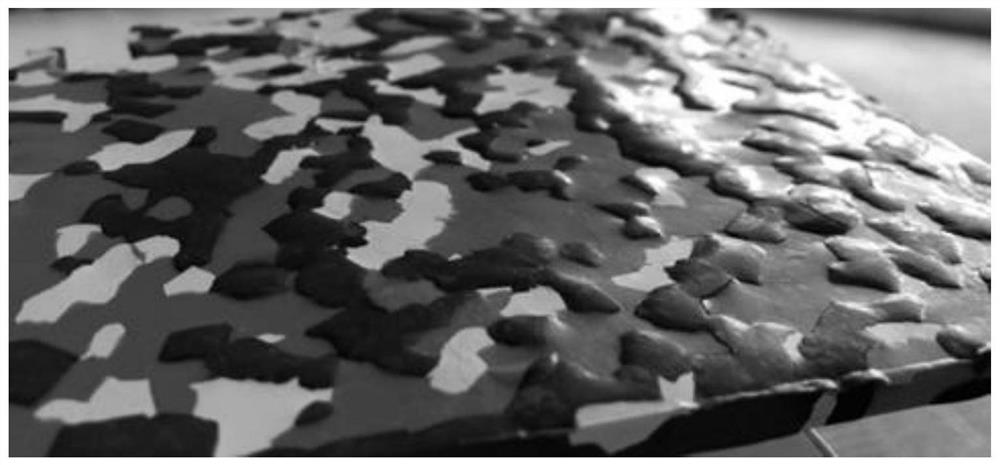

[0081] figure 1 It is a photograph of the composite rubber obtained in Example 1.

[0082] Composite rubber molding preparation obtained in embodiment 1 figure 2 The sole of the pattern shown, in which the toe of the sole is thin horizontal stripes, the width of the stripes and the width between the stripes are both 0.5mm, and the depth of the stripes is 0.5mm; The width of the gro...

Embodiment 2

[0089] The preparation method is the same as in Example 1, except that foamed rubber particles and non-foamed rubber particles are mixed according to the mass ratio of 20:80.

[0090] The properties of the composite rubber obtained in Example 2 were tested, and the results obtained are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com