Tire tread, manufacturing method thereof and tire

A technology for tire tread and rubber compound, which is applied in the direction of tire tread/tread pattern, tire parts, tires, etc., can solve the problems of difficulty in taking into account rolling resistance performance and high wet skid resistance, and single tread performance. , to achieve the effect of breaking through the design limitations, improving the tire label grade, and strengthening the inclusiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

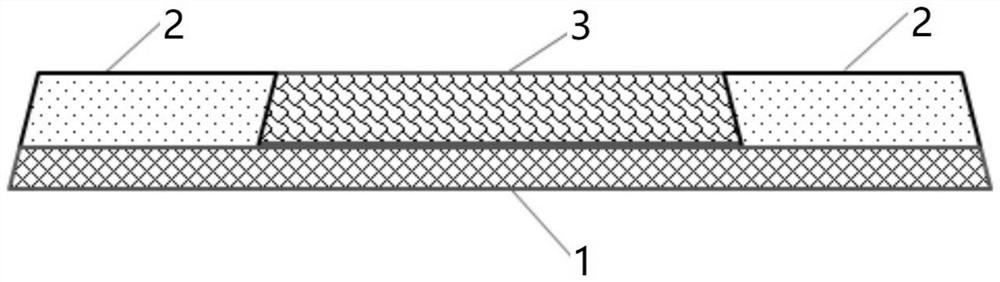

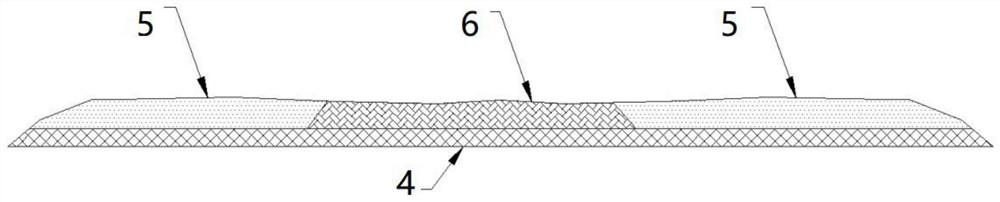

[0057] The embodiment of the present application provides a tire tread and a tire, and the specific steps are as follows:

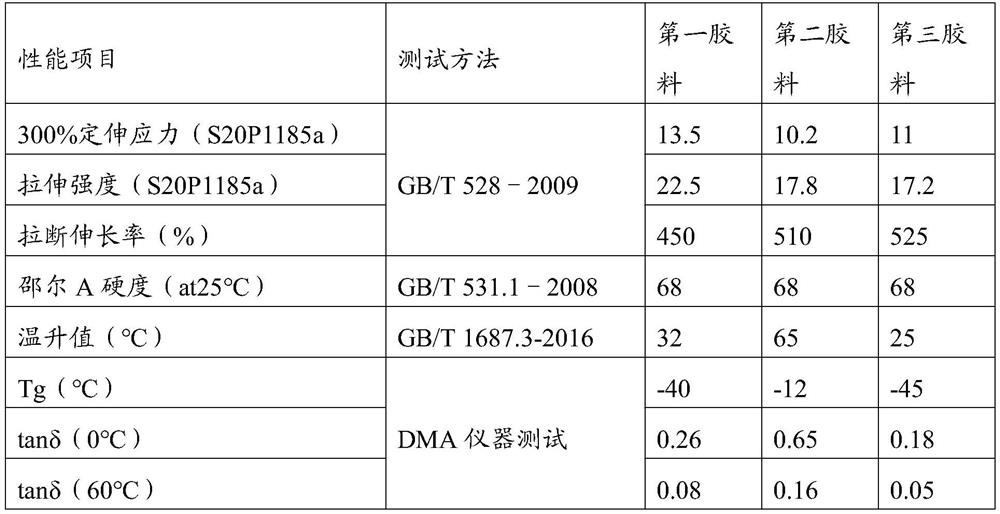

[0058] 1. Prepare the first sizing material, the second sizing material and the third sizing material. In parts by weight, the first sizing material comprises: 70 parts of natural rubber, 30 parts of non-oil-extended polystyrene butadiene rubber, 40 parts of carbon black, 10 parts of white carbon black, 2 parts of process oil, 2 parts of solid silane coupling agent, 4.5 parts of tackifying resin, 3 parts of anti-aging agent, 8 parts of active agent, 1.8 parts of accelerator and 3 parts of vulcanizing agent.

[0059] Specifically, non-oil-extended polystyrene-butadiene rubber is a product of Taiwan Rubber Company, the mass content of styrene in non-oil-extended polystyrene-butadiene rubber is 10%, and the mass content of vinyl in butadiene in non-oil-extended polystyrene-butadiene rubber is 40%, the glass transition temperature (DSC) of non-oil-extended st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com