Reinforcing structure for purline tenon

A technology for strengthening structures and purlins, applied in building construction, building maintenance, construction, etc., can solve problems such as overall inclination, high maintenance costs, and incompatibility of reinforcement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

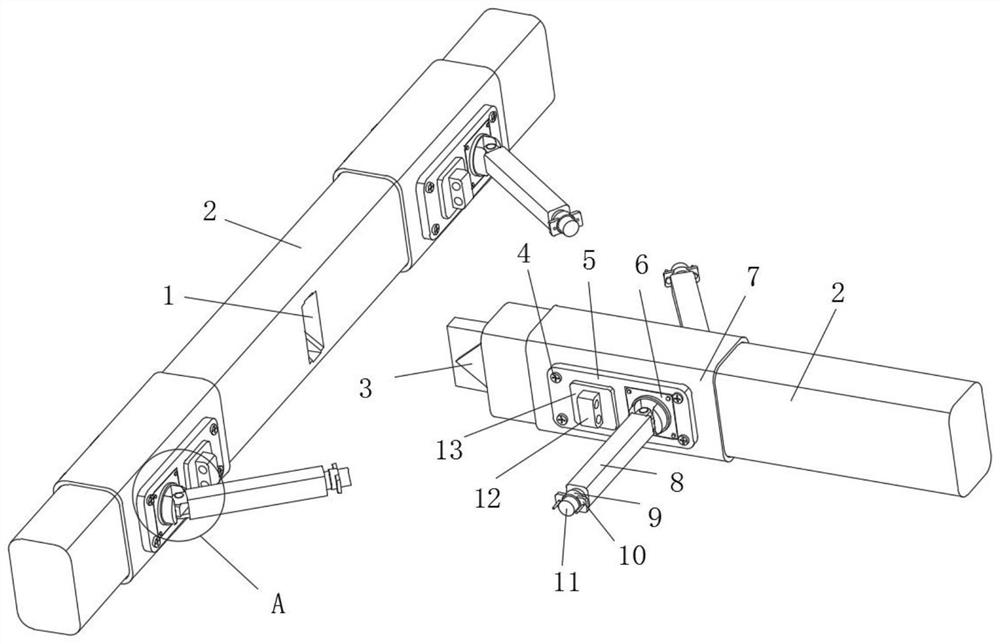

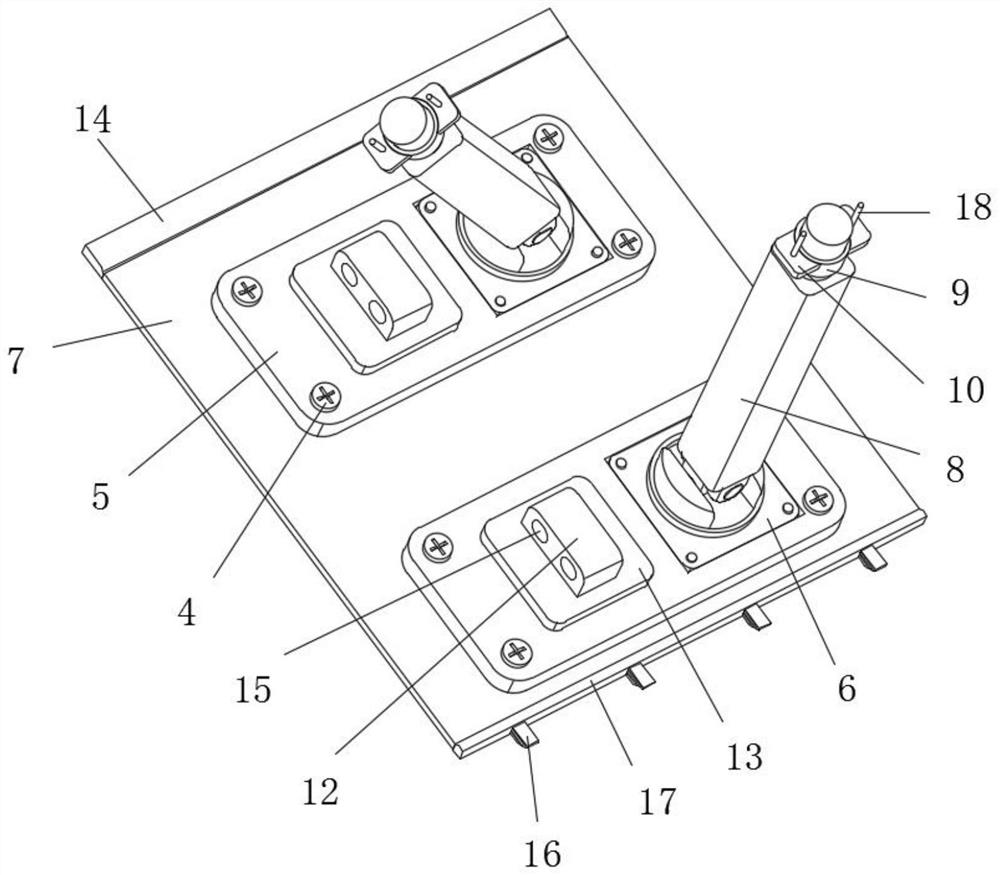

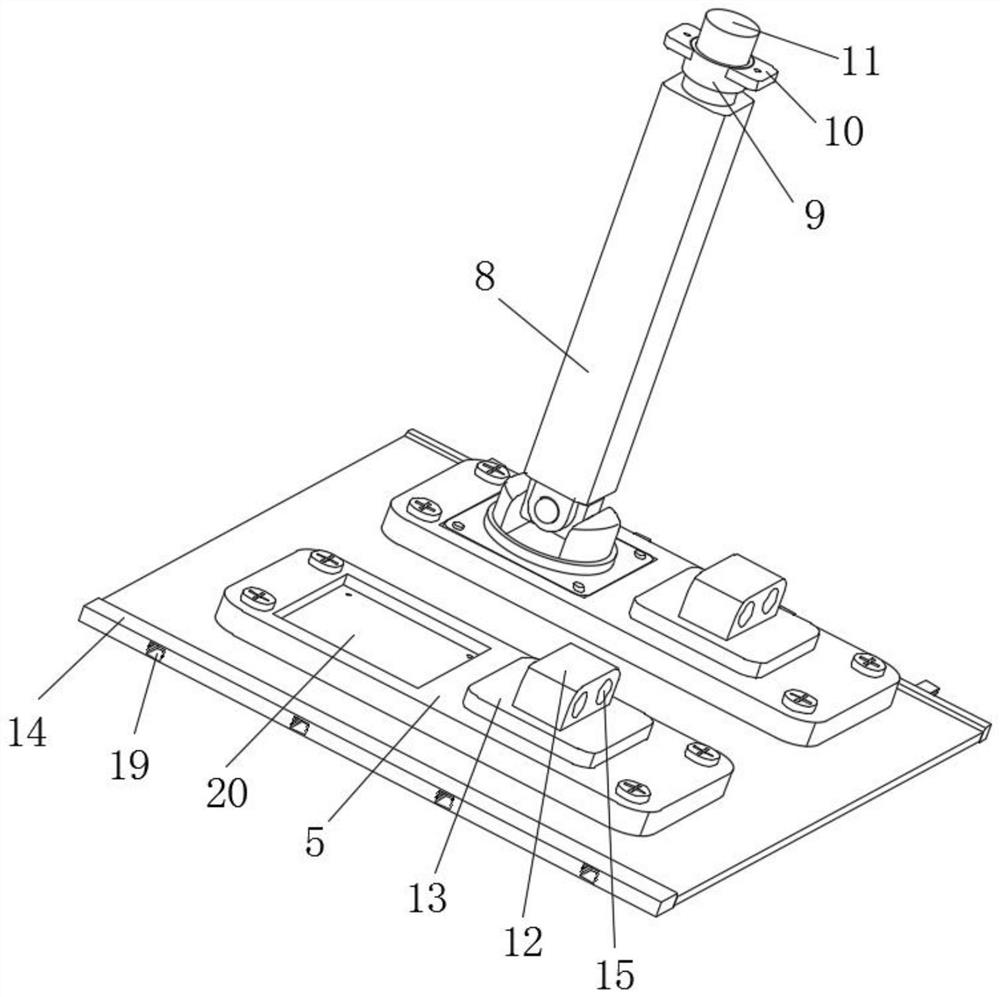

[0028] Embodiment 1: as Figure 1-7 As shown, the present invention provides a technical solution: a reinforcement structure for purlin tenon, including tenon groove 1, purlin 2 and tenon head 3, tenon groove 1 and tenon head 3 are respectively arranged at the joint of purlin 2, and purlin 2 is close to A fixed strip 7 is placed on the surface of the tenon 3, and the two ends of the fixed strip 7 are fixedly connected by a connecting device, and the positions on the surface of the fixed belt 7 corresponding to both sides of the purlin 2 are fixedly installed with a fixed plate 5, and the fixed plate 5 Screws 4 are provided on the four corners, the screws 4 penetrate the fixing plate 5 and the fixing strip 7 and extend into the interior of the purlin 2, the screws 4 are screwed to the purlin 2, and the surface of the fixing plate 5 is respectively provided with a first connecting plate 6 and the second connecting plate 13, the surface of the first connecting plate 6 is provided...

Embodiment 2

[0037] Embodiment 2: as Figure 1-7 As shown, the present invention provides a technical solution: a reinforcement structure for purlin tenon, including tenon groove 1, purlin 2 and tenon head 3, tenon groove 1 and tenon head 3 are respectively arranged at the joint of purlin 2, and purlin 2 is close to A fixed strip 7 is placed on the surface of the tenon 3, and the two ends of the fixed strip 7 are fixedly connected by a connecting device, and the positions on the surface of the fixed belt 7 corresponding to both sides of the purlin 2 are fixedly installed with a fixed plate 5, and the fixed plate 5 Screws 4 are provided on the four corners, the screws 4 penetrate the fixing plate 5 and the fixing strip 7 and extend into the interior of the purlin 2, the screws 4 are screwed to the purlin 2, and the surface of the fixing plate 5 is respectively provided with a first connecting plate 6 and the second connecting plate 13, the surface of the first connecting plate 6 is provided...

Embodiment 3

[0046] Embodiment 3: as Figure 1-7 As shown, the present invention provides a technical solution: a reinforcement structure for purlin tenon, including tenon groove 1, purlin 2 and tenon head 3, tenon groove 1 and tenon head 3 are respectively arranged at the joint of purlin 2, and purlin 2 is close to A fixed strip 7 is placed on the surface of the tenon 3, and the two ends of the fixed strip 7 are fixedly connected by a connecting device, and the positions on the surface of the fixed belt 7 corresponding to both sides of the purlin 2 are fixedly installed with a fixed plate 5, and the fixed plate 5 Screws 4 are provided on the four corners, the screws 4 penetrate the fixing plate 5 and the fixing strip 7 and extend into the interior of the purlin 2, the screws 4 are screwed to the purlin 2, and the surface of the fixing plate 5 is respectively provided with a first connecting plate 6 and the second connecting plate 13, the surface of the first connecting plate 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com