Pump suction type external circulation cooling device for lubricating oil in vibration box of hydraulic vibration pile driver

A technology of hydraulic vibration and extracorporeal circulation, applied in the direction of engine lubrication, engine components, lubricating parts, etc., can solve the problems of lubricating oil aging, thick shell, poor heat dissipation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

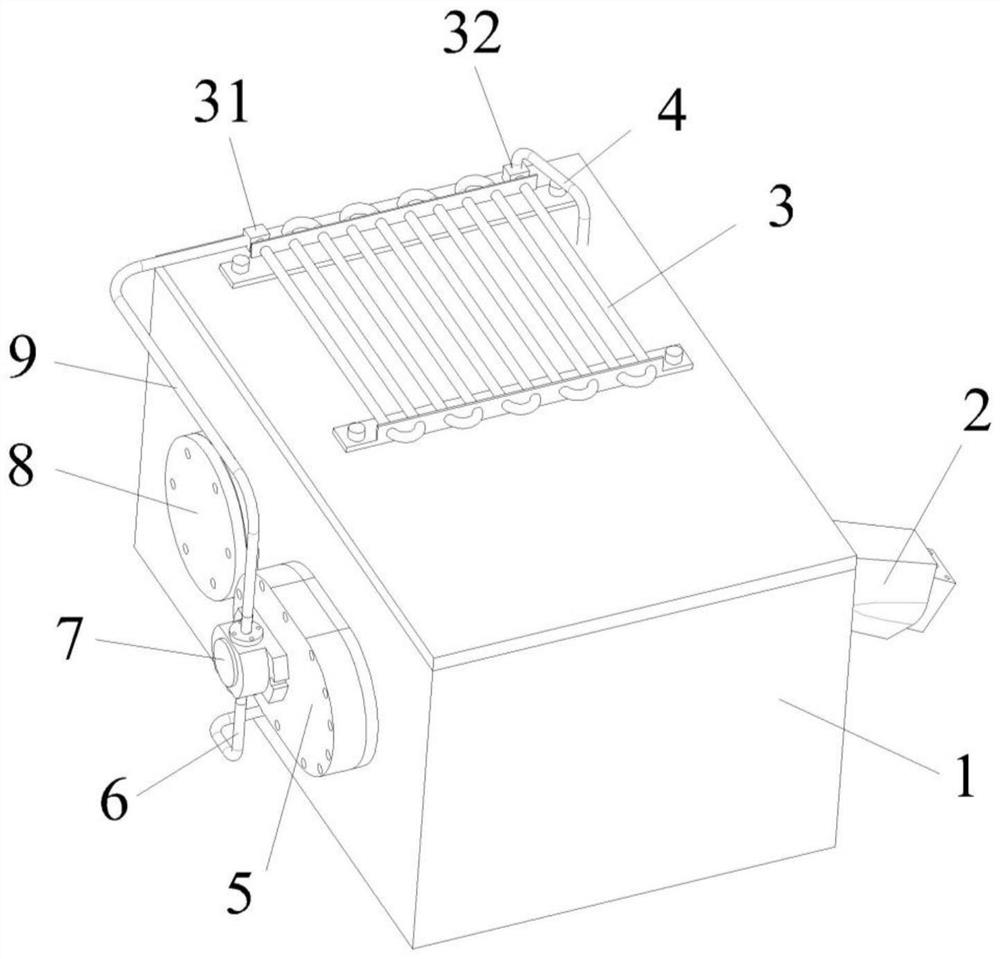

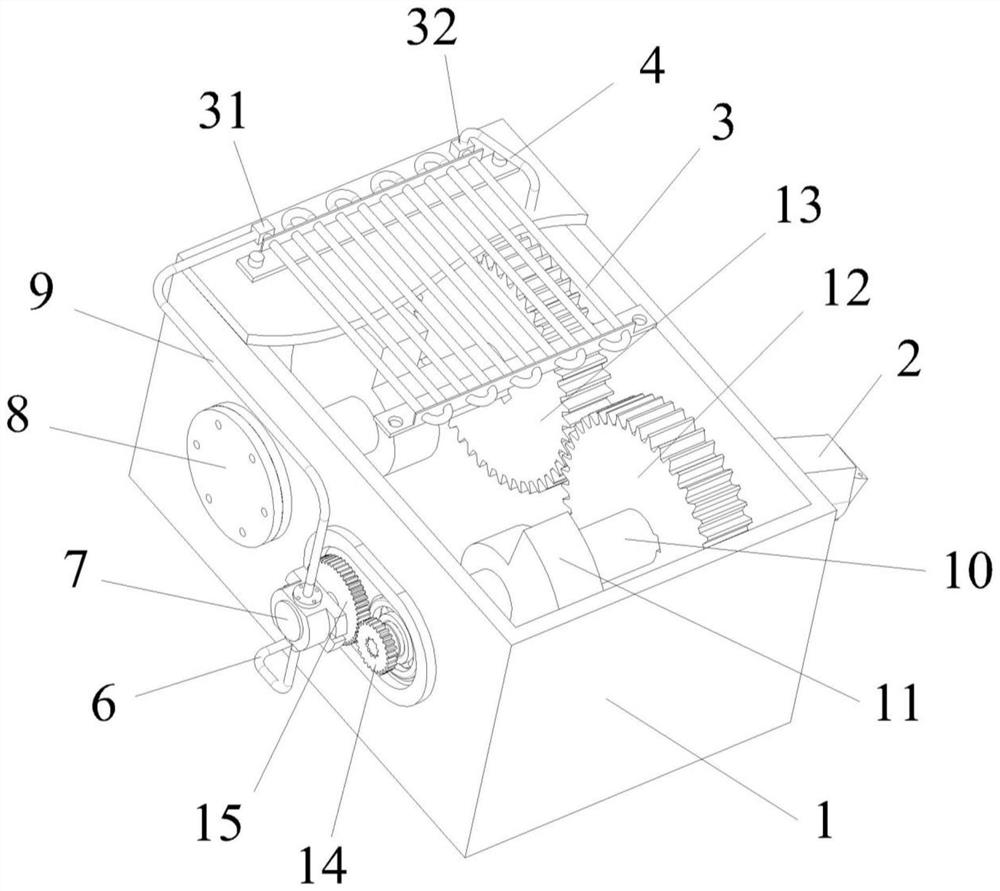

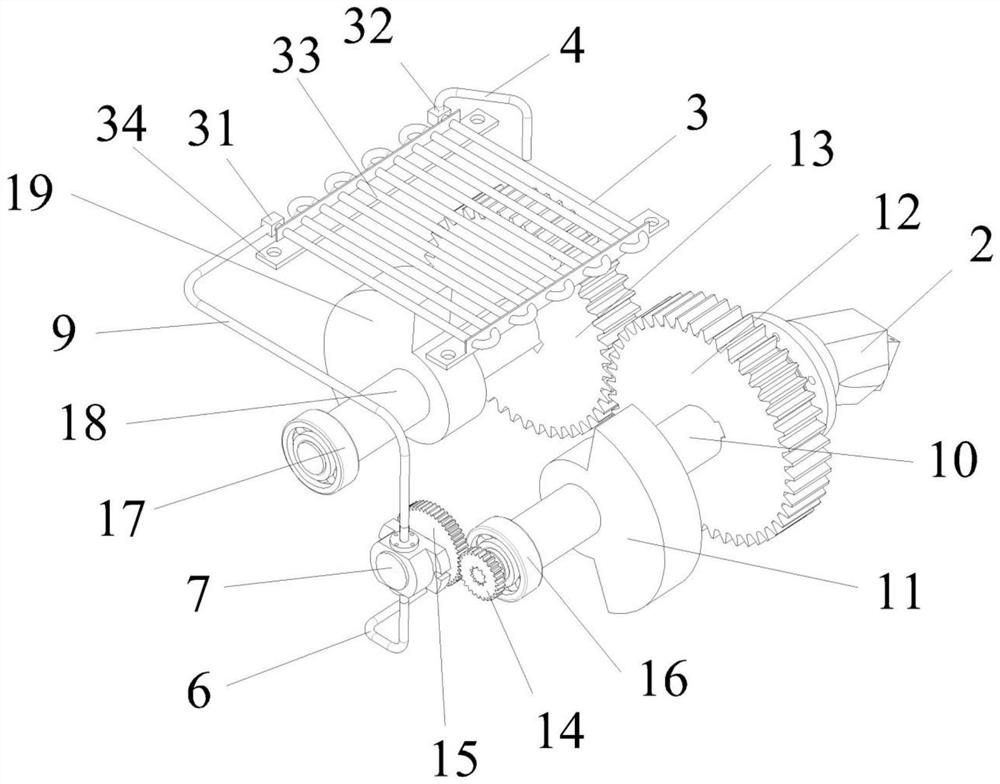

[0040] Such as Figure 1 to Figure 12 As shown, the pump-suction extracorporeal circulation cooling device for lubricating oil in the vibration box of the hydraulic vibration pile driver includes a vibration box 1, a radiator 3, a driving shaft 10, a driven shaft 18 and an oil suction pump 7; the radiator 3 is installed in the vibration box 1 on any shell surface; the driving shaft 10 is supported on the shell of the vibration box 1 through the first support bearing 16, and is fixed in the vibration box 1 through the first end cover 5; the driven shaft 18 passes through the second support bearing 17 Supported on the shell of the vibration box 1, fixed in the vibration box 1 through the second end cover 8; the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com