A fiber grating strain detection device

A detection device and fiber grating technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of inconvenience of different specifications of fiber gratings and reduced detection efficiency, and achieve the effect of improving accuracy, smooth operation, and convenient relative position.

Active Publication Date: 2022-06-03

NO 59 RES INST OF CHINA ORDNANCE IND

View PDF23 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Fiber Bragg grating needs strain detection in the actual production and processing process. The existing strain detection device is not convenient to control the detection feed rate for different specifications of fiber gratings, which reduces the actual detection efficiency; therefore, it is necessary to carry out the existing technology Improve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

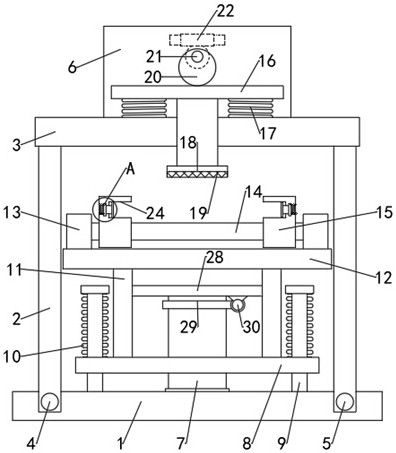

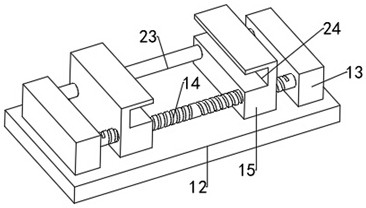

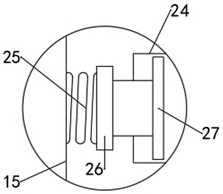

The invention discloses an optical fiber grating strain detection device, which comprises a base on which a support frame is movably installed, the end of the support frame away from the base is connected with a mounting seat, and the upper end surface of the mounting seat is fixed with a drive chamber; The optical fiber grating strain detection device controls the vertical feed of the fixed seat through the lifting screw, which is convenient for adjusting the distance between the optical fiber grating and the pressure block, so that it is suitable for the detection of optical fiber gratings of different specifications; the eccentric wheel is driven by the meshing of the worm gear, It is convenient to control the feed rate of the pressure plate and improve the detection accuracy; by setting a limit block in the limit groove, it is convenient to control the clamping force of the fiber grating and avoid damage; through the cooperation of the guide rod and the guide spring, the fixed seat The operation is stable and easy to adjust; in addition, the straight movement of the mounting seat is controlled by the feed screw, which is convenient for controlling the relative position of the pressure block and the fiber grating, and realizes multi-point detection.

Description

A fiber grating strain detection device technical field The present invention relates to a kind of detection equipment, specifically a kind of fiber grating strain detection device. Background technique Fiber grating is a kind of fiber grating which is formed by periodically modulating the refractive index of the fiber core by a certain method. The diffraction grating is a kind of passive filter element, because the grating fiber has small size, low splice loss, and is fully compatible with optical fiber, It can be embedded in smart materials and other advantages, and its resonant wavelength is sensitive to changes in the external environment such as strain, refractive index, concentration, etc. Therefore, it has been widely used in the field of optical fiber communication and sensing. Fiber grating needs to be in the actual production and processing process For strain detection, the existing strain detection device is inconvenient to control the detected feed amoun...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/16

Inventor 何建新周漪王成章舒畅廖光萌佘祖新周堃朱玉琴李超杨小奎赵方超

Owner NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com