Sample preparation device

A technology of an opening device and a casing is applied in the field of oil and gas exploration, and can solve the problems of difficulty in sampling natural fracture-cavity carbonate rocks, large differences in the distribution rules of natural pores and fractures, and large differences in natural rock samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

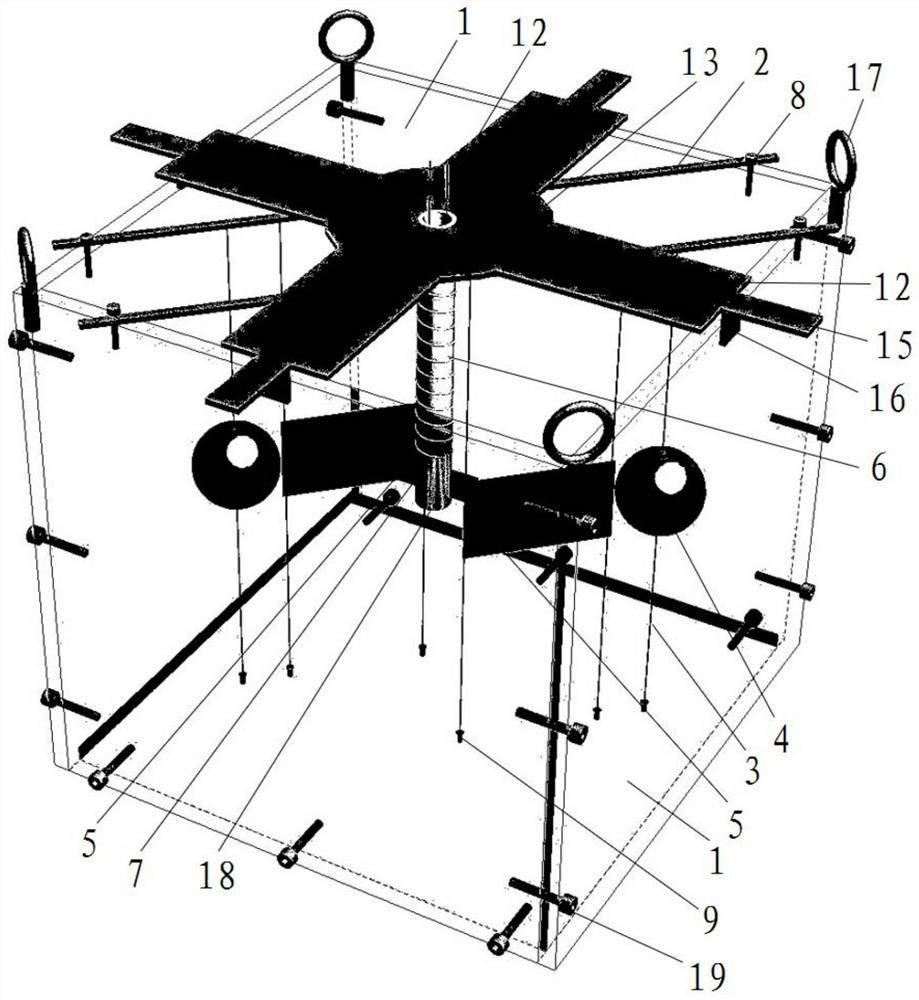

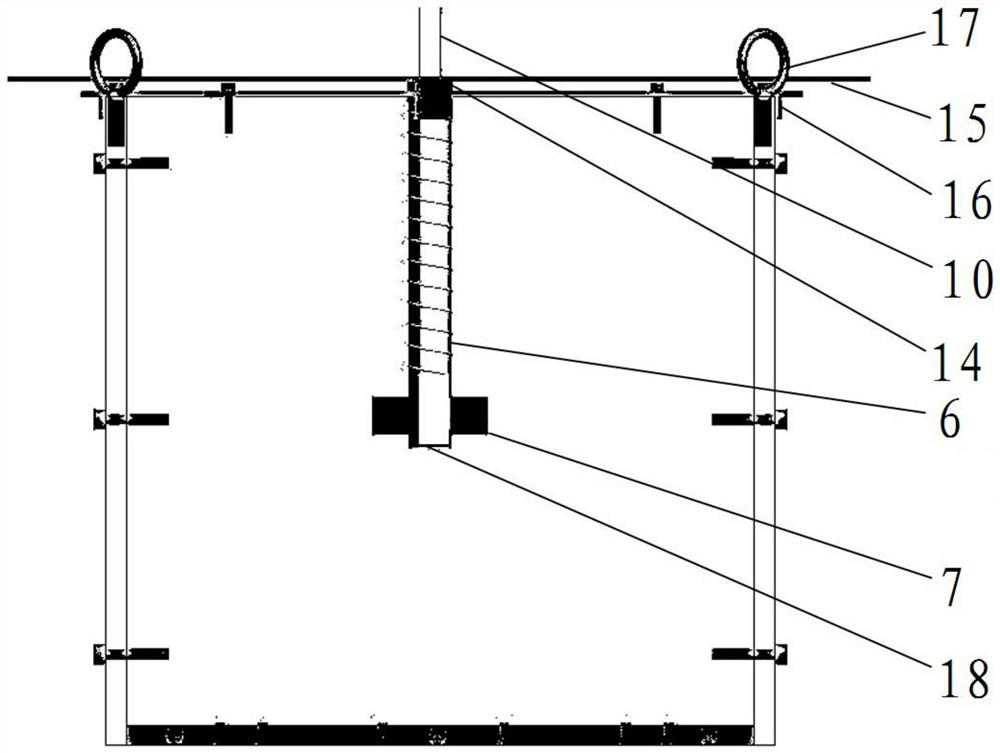

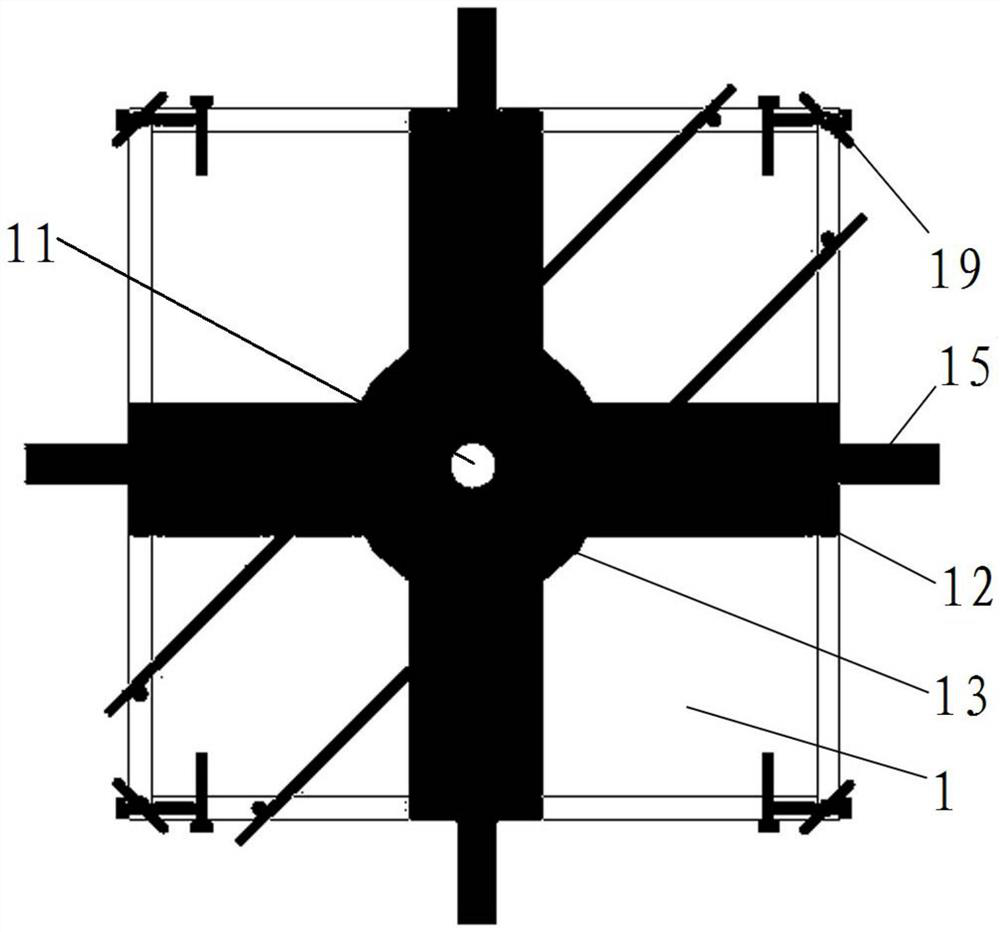

[0023] The embodiment of the present invention provides a sample preparation device to realize various fracture and hole layouts. On this basis, the indoor fracture-cavity carbonate rock targeted fracturing test can be carried out, which is beneficial to find out different fractures. The different effects of the distribution of caves on fracture initiation and expansion in targeted fracturing tests can be used to guide the exploration and development of oil and gas in actual fracture-cavity and fault-karst carbonate reservoirs.

[0024] The technical solutions in the embodiments of the present invention are to achieve the above-mentioned technical effects, and the general idea is as follows:

[0025] The support rod is arranged on the top of the upper opening device shell; the upper end of the connection line is connected with the support rod, and the lower end of the connection line is connected with the bottom of the upper opening device shell; the film storage body and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com