Simulation test device for directional drilling grouting slurry diffusion

A simulation test, directional drilling technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to easily fix and install protective structures, drilling, and inability to protect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

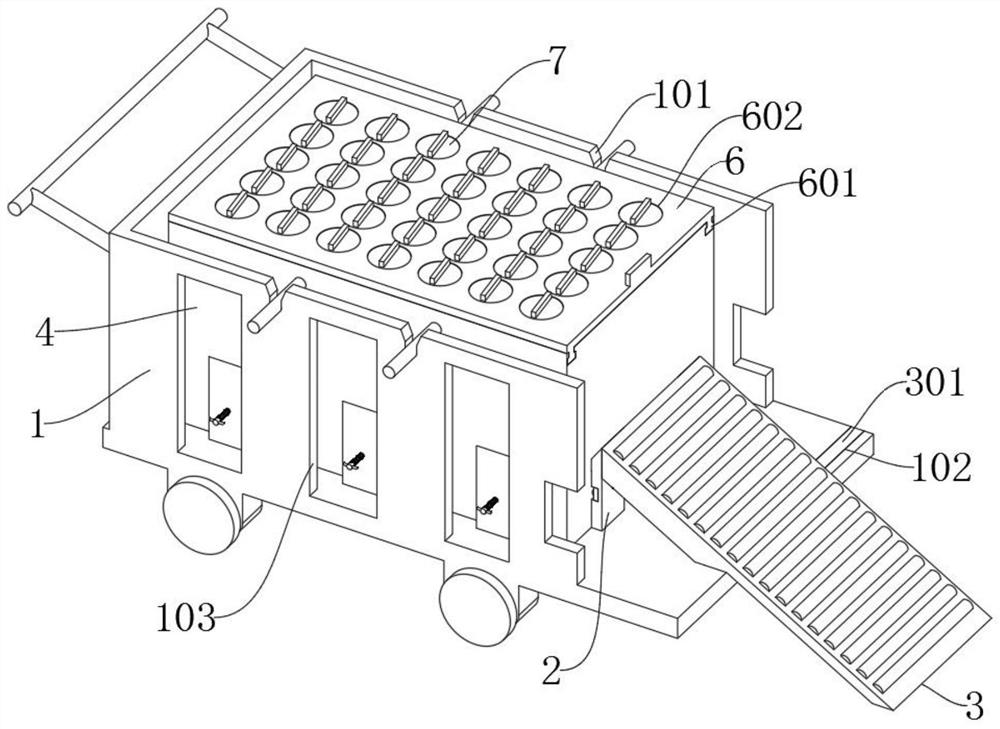

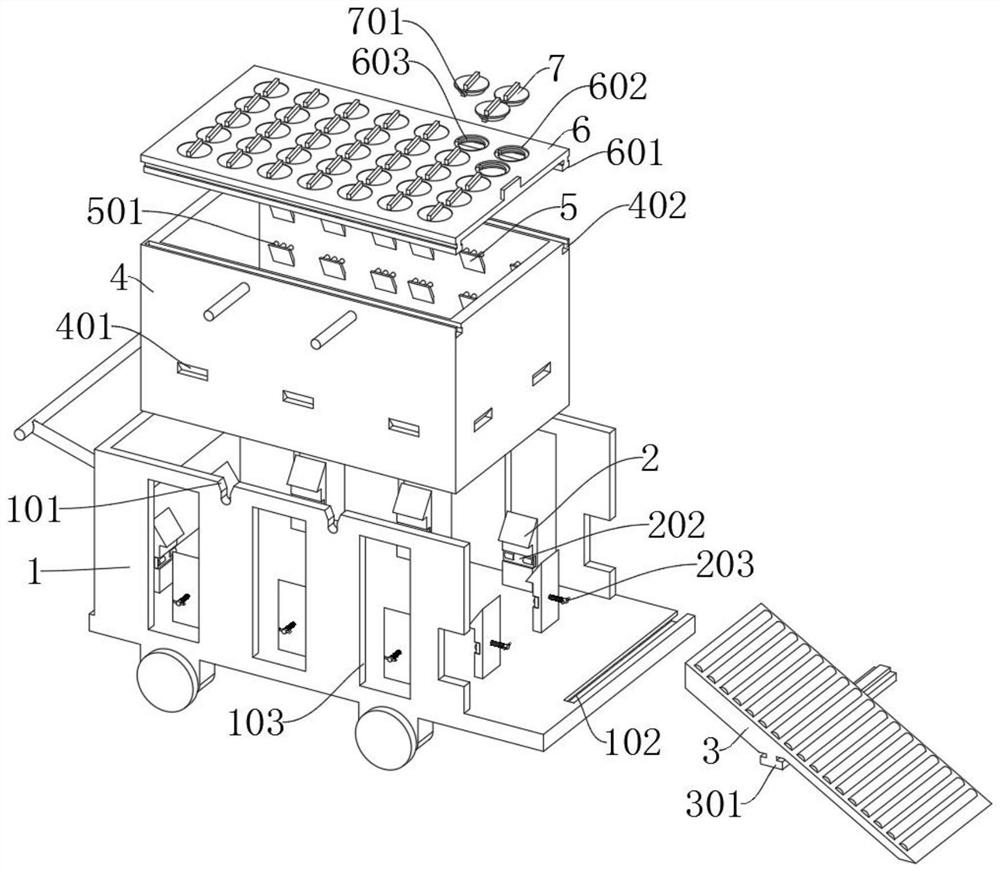

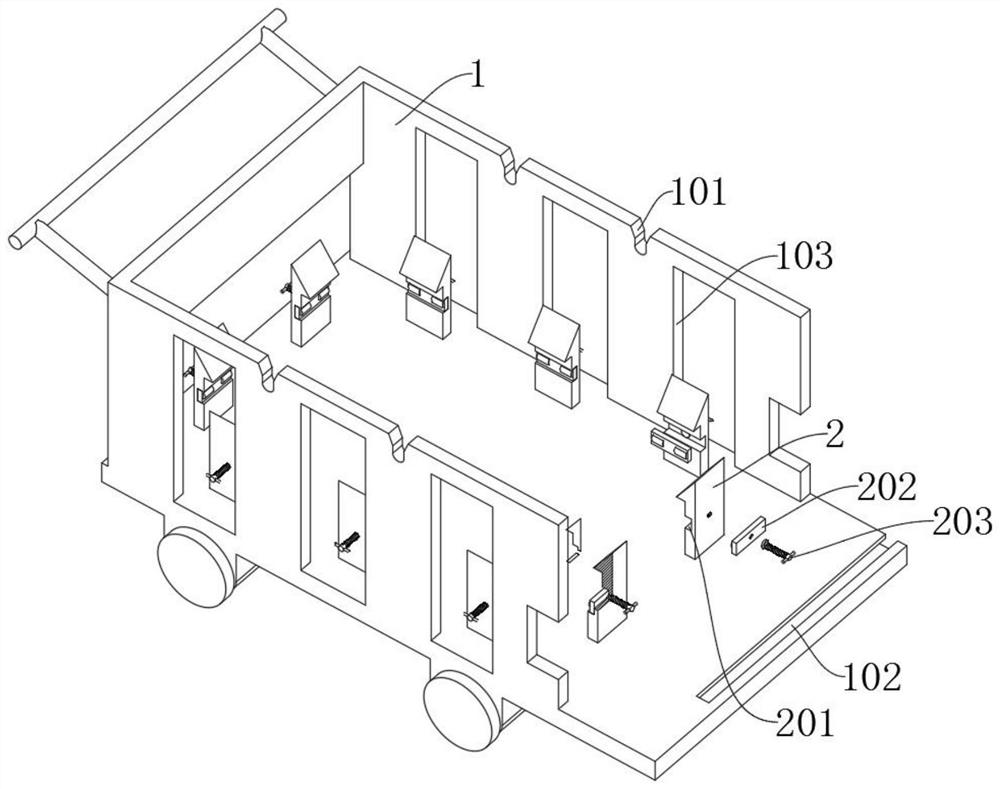

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a simulation test device for the diffusion of directional drilling grouting grout, which includes a main body 1, a block 2, a guide 3, a protective part 4, a buffer plate 5, a sealing plate 6 and a rotating part 7; the main body 1 is a rectangular structure , and the bottom of the main body 1 is provided with a moving wheel; the guide 3 is installed on the front end of the main body 1, and the connecting block 301 of the guide 3 is embedded in the installation hole 102; the guard 4 is installed on the inner bottom of the main body 1, And the top of the block 2 is embedded in the slot 401 of the protective piece 4; the buffer plate 5 and the support rod 501 are evenly fixed on both sides of the protective piece 4 by bonding; the rotating member 7 is installed inside the insertion hole 602 , and the fixed block 701 of the rotary member 7 is at the bottom of the block 603 through the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com