Control motor for electric VVT

A technology of electric motor and casing, which is applied in the field of electric VVT control motor, which can solve the problems of poor sealing, motor influence, and affecting the practical life of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

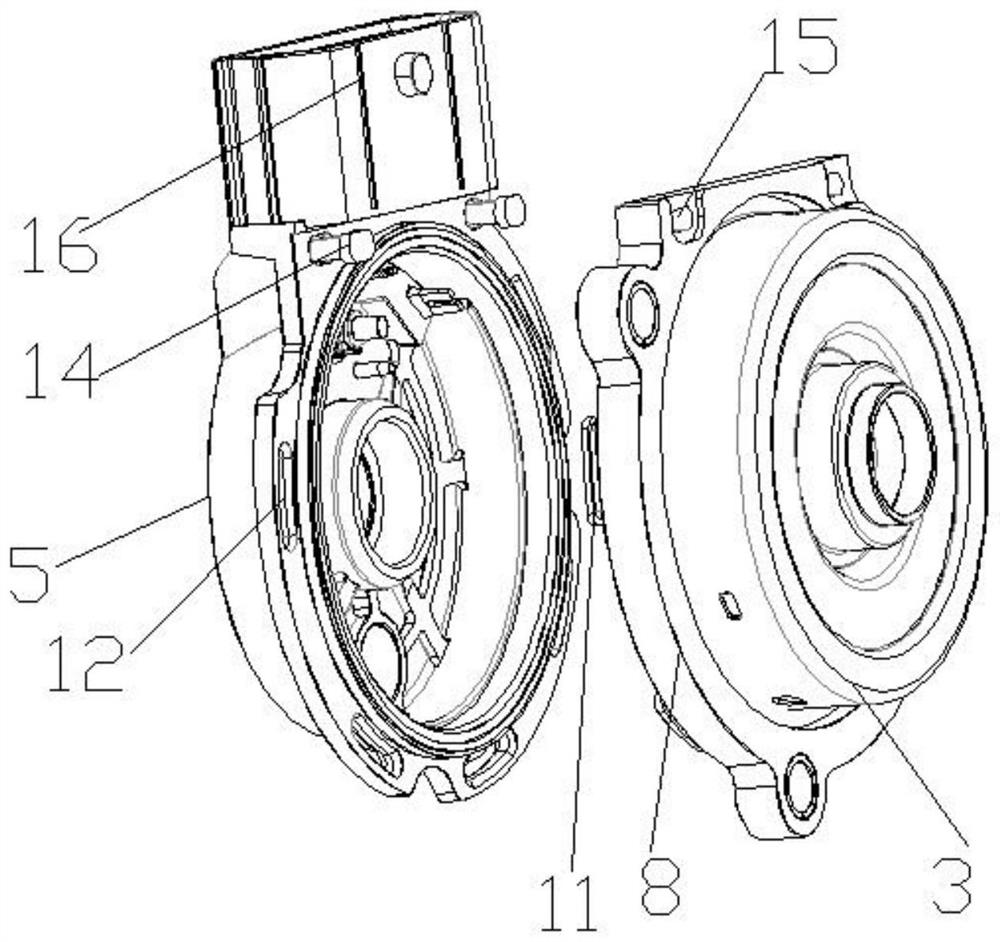

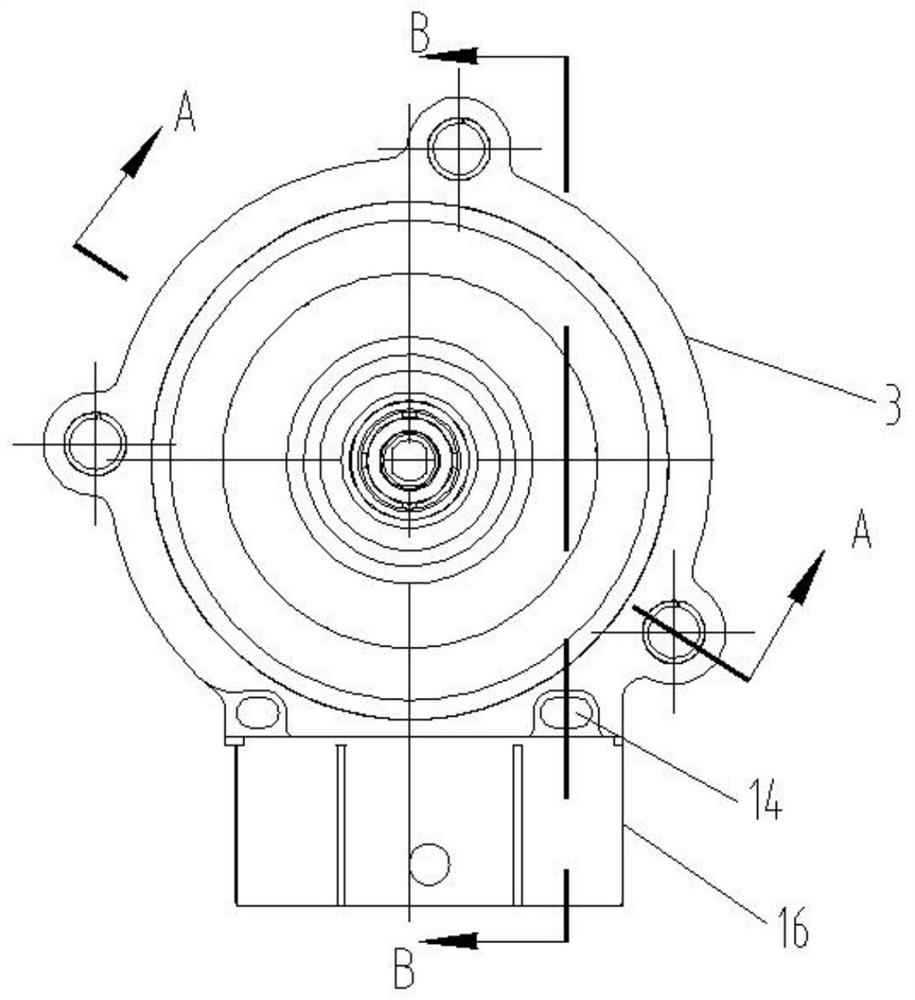

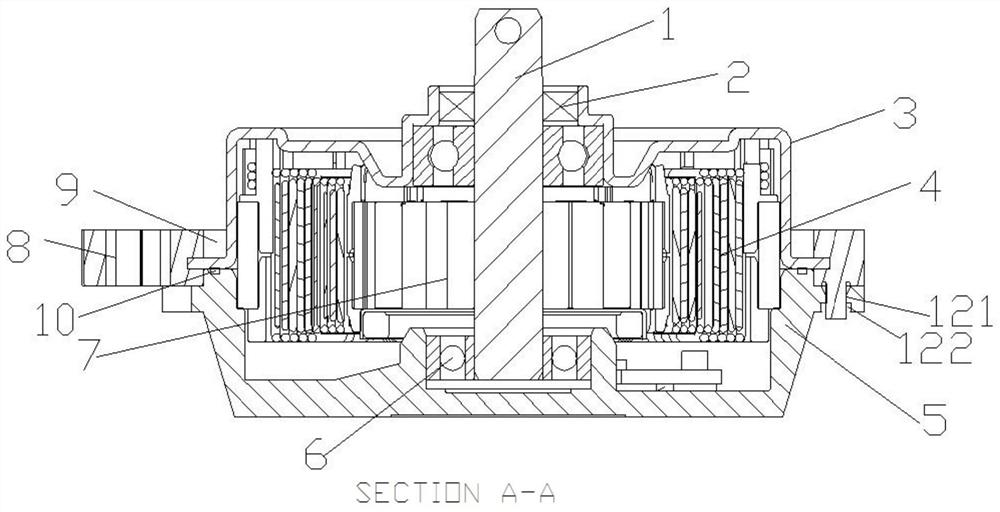

[0029] A control motor for an electric VVT, such as Figure 1-5 As shown, it includes a casing 3 and a plastic flange 5, the bottom of the casing 3 is an injection molding edging structure 8, and the outer periphery of the plastic flange 5 is integrally molded with a connector 16, and the plastic flange 5 A number of plastic bosses-14 are evenly distributed at the connection with the connecting machine 16, and the injection molding wrapping structure 8 at the bottom of the casing 3 is provided with a through hole-15 corresponding to the injection molding boss-14. Column one 14 is tightly connected with said through hole one 15; said injection molding encapsulation structure 8 is provided with several plastic convex columns two 11 along the circumferential direction, and said plastic flange plate 5 is provided with along the circumferential direction The second plastic post 11 corresponds to a plurality of second through holes 12, and the second plastic post 11 is tightly conne...

Embodiment 2

[0032] Based on the above-mentioned embodiment 1, the injection molding encapsulation structure 8 is provided with several through holes 12 along the circumferential direction, and the plastic flange 5 is provided with several plastic protrusions corresponding to the through holes 12 along the circumferential direction. The second post 11, the second plastic post 11 is firmly connected with the second through hole 12. In this embodiment, another structural form in which the injection molding wrapping structure 8 at the bottom of the casing and the plastic flange 5 are fastened and connected by setting plastic protrusions 11 and through holes 12 is described, that is: injection molding The edge structure 8 is provided with a plurality of through holes 12 in the circumferential direction, and the plastic flange 5 is provided with a plurality of plastic protrusions 11 corresponding to the through holes 12 along the circumferential direction, and the plastic protrusions 11 Realize...

Embodiment 3

[0034] Based on the above-mentioned embodiment 1 or 2, after the plastic boss 14 passes through the through hole 15, welding is used to realize the fast connection between the plastic boss 14 and the through hole 15, and the plastic boss 2 11 passes through the through hole. After the second hole 12, welding is used to realize the fastening connection between the second plastic post 11 and the second through hole 12; in this embodiment, the first plastic post 14 and the first through hole 15 as well as the second plastic post 11 and the through hole are specifically described. The fastening connection method of two 12, that is, the fastening connection between the plastic convex post 11 and the through hole 12 is realized by welding after the plastic post 11 passes through the through hole 12. Similarly, the plastic post 14 and the through hole 15 are also connected. Connect as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com