Ceiling splicing method of color steel sandwich panel

A sandwich panel and color steel technology, which is applied to ceilings, buildings, building components, etc., can solve the problems of poor flatness of the surface of the house and different horizontal positions of the color steel sandwich panels, so as to improve the flatness and improve the aesthetics , to ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

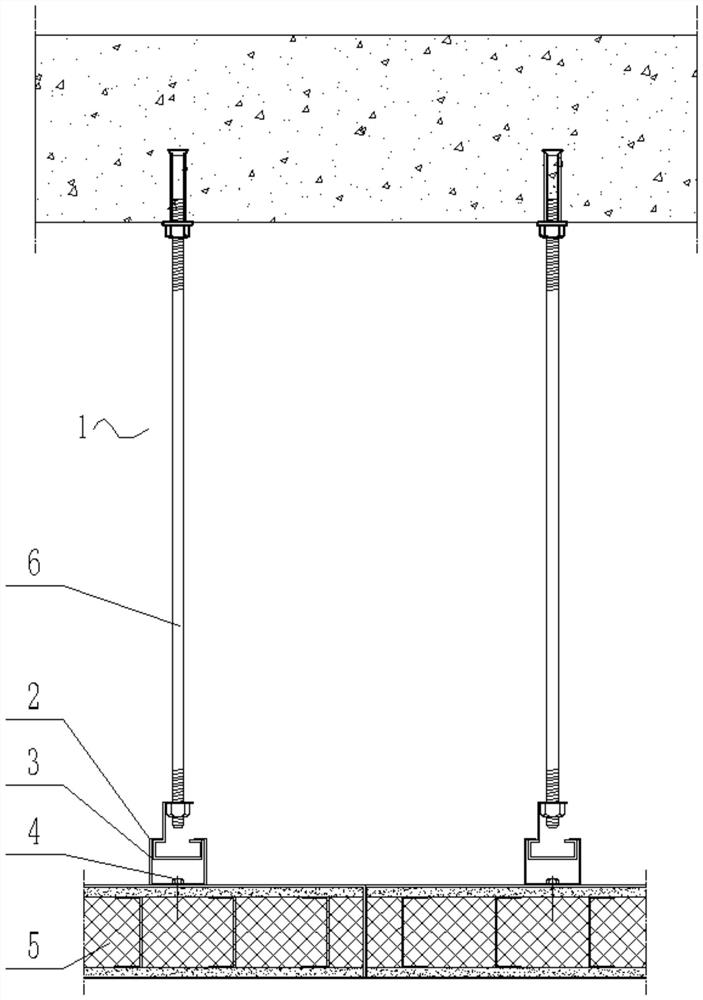

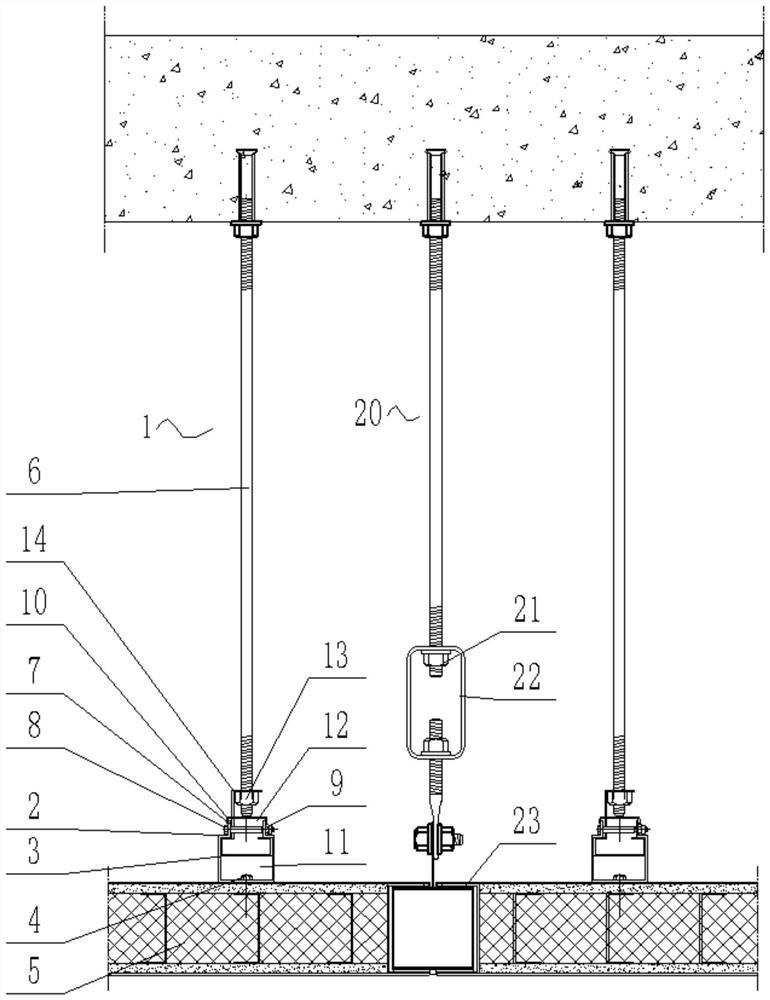

[0047] Such as Figure 2~Figure 7 As shown in the ceiling splicing method of color steel sandwich panels of the present invention, there are a plurality of color steel sandwich panels, which are laid sequentially from left to right along a horizontal line, and the color steel sandwich panels are sequentially laid from left to right It is the first color steel sandwich panel, the second color steel sandwich panel...the Nth color steel sandwich panel, where N is a natural number and N is greater than or equal to 2;

[0048] The ceiling splicing method includes the following steps:

[0049] Hoisting the N-1 color steel sandwich panel:

[0050] S1. Install the expansion head of the long rod expansion bolt 1 in the cement roof at the ceiling;

[0051] S2. Screw the groove bottom of the C-shaped main bar steel 2 to the rock wool double-glass magnesium color steel sandwich panel that needs to be hoisted through the screw 4;

[0052] S3. Slidingly install the C-shaped auxiliary bar...

Embodiment 2

[0066] This embodiment is an illustration of the implementation of the connecting component A in the first embodiment.

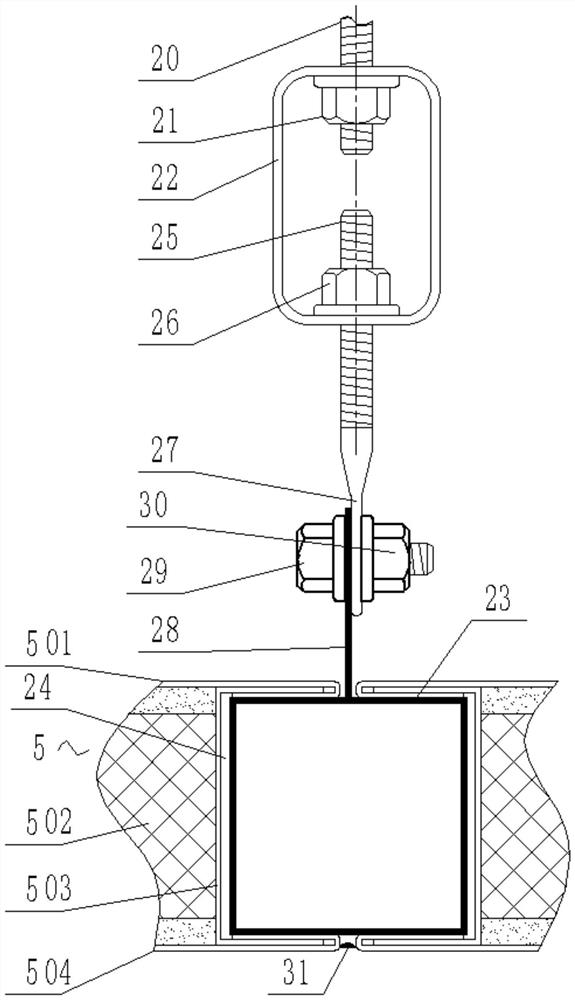

[0067] Such as figure 2 and image 3 As shown, in the present invention, the connecting assembly A includes a lower screw rod 25, a lower nut 26, a lower connecting plate 27, an intermediate connecting plate 28, a fastening bolt 29 and a fastening nut 30, and the top of the lower screw rod 25 hangs through The lower side of the intermediate connector 22 is threadedly connected with the lower nut 26, the bottom of the lower screw rod 25 is connected with the lower connecting plate 27, one side of the intermediate connecting plate 28 fits with the lower connecting plate 27, and its bottom is connected with the positioning bar 23 , the end of the rod portion of the fastening bolt 29 moves through the lower connecting plate 27 and the middle connecting plate 28 in turn, and then is threadedly connected with the fastening nut 30 .

[0068] The connecting piece...

Embodiment 3

[0070] This embodiment is based on the above-mentioned embodiments, and makes an implementation description of the end structure of the color steel sandwich panel 5 .

[0071] Such as image 3 As shown, in the present invention, the color steel sandwich panel 5 includes two metal panels A501 and metal panels B504 that are parallel to the horizontal plane and oppositely arranged up and down. The core 502 and the end strip 503 arranged between the metal panel A501 and the metal panel B504, the cross section of the end strip 503 is U-shaped, the middle part of its convex surface is in contact with the heat-insulating inner core 502, and its inner side The through groove is the chute 24, and the ends of the metal panels A501 and B504 near the end strips 503 extend along the side panels of the end strips 503 until they extend to the ends of the side panels. After that, they extend towards each other, and then extend to the side of the side panels of the end strips 503 facing each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com