Tail gas scrubbing tower adopting gas-liquid separation membrane

A technology of tail gas scrubber and gas-liquid separation membrane, which is applied in the field of tail gas scrubber, can solve the problems of many scrubbing liquid components, poor gas-liquid separation effect, and inconvenient use, so as to improve the gas-liquid separation effect and realize gas-liquid separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

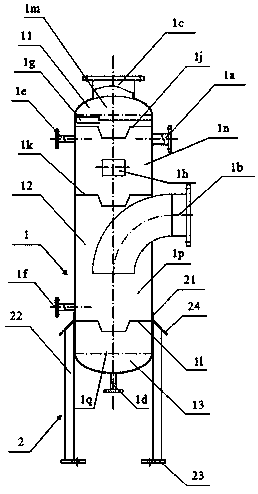

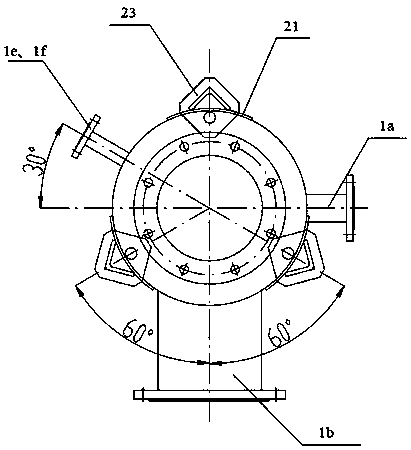

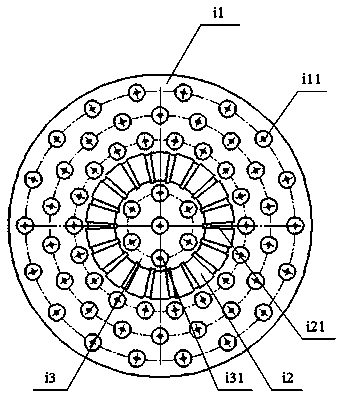

[0023] like Figure 1-4 As shown, a tail gas scrubber using a gas-liquid separation membrane is composed of a tower body 1 and a fixed part 2 located below the tower body 1. The tower body 1 includes a top 11 that is in the shape of a circular arc at the top, and a circular arc at the bottom. The arc-shaped bottom 13 and the hollow cylindrical middle part 12 between the top 11 and the bottom 13; the middle part 12 and the bottom 13 are connected by welding to ensure the connection strength and the internal tightness of the tower body. The middle part 12 and the top 11 are connected through the locking part 1g, so that the top 11 can be opened through the locking part 1g to replace and maintain the gas-liquid separation membrane inside the tower body; The membrane 1j, the second separation membrane 1k, and the third separation membrane 1l are separated into a top escape chamber 1m, a first separation chamber 1n, a second separation chamber 1p, and a bottom deposition chamber 1q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com