Punch press table body with protection device and automatic feeding function

A technology of automatic feeding and protection devices, applied in the field of stamping equipment, can solve problems such as labor costs, and achieve the effects of reducing labor costs, saving operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

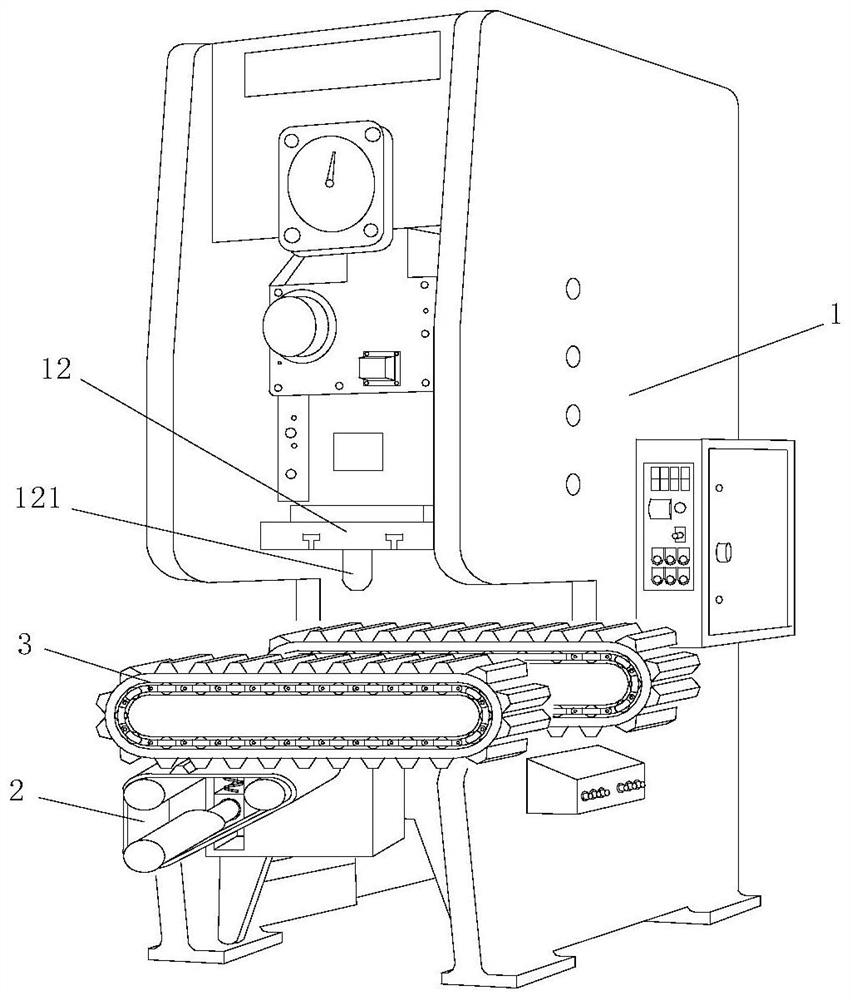

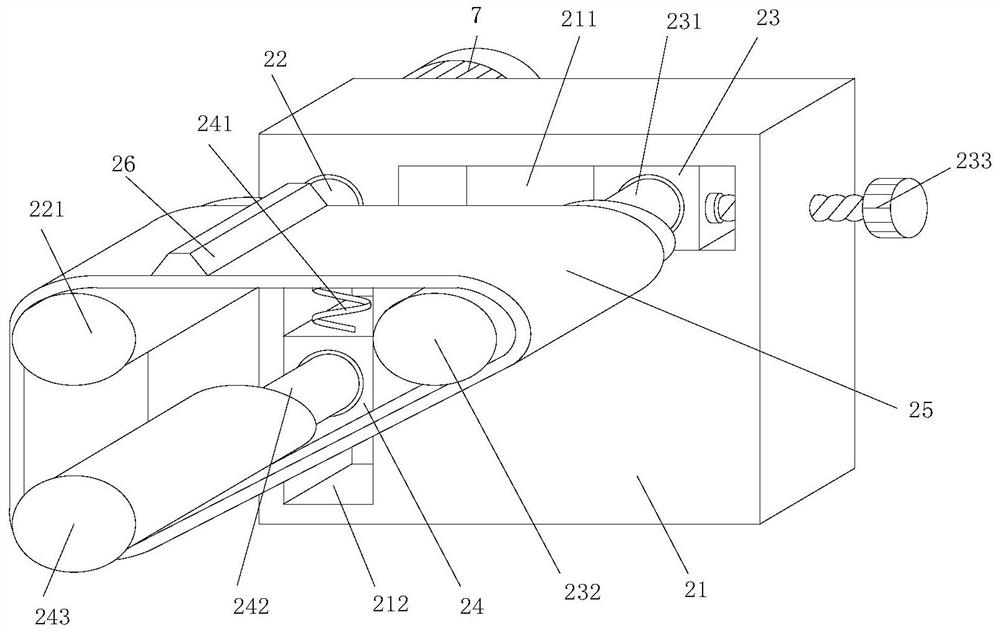

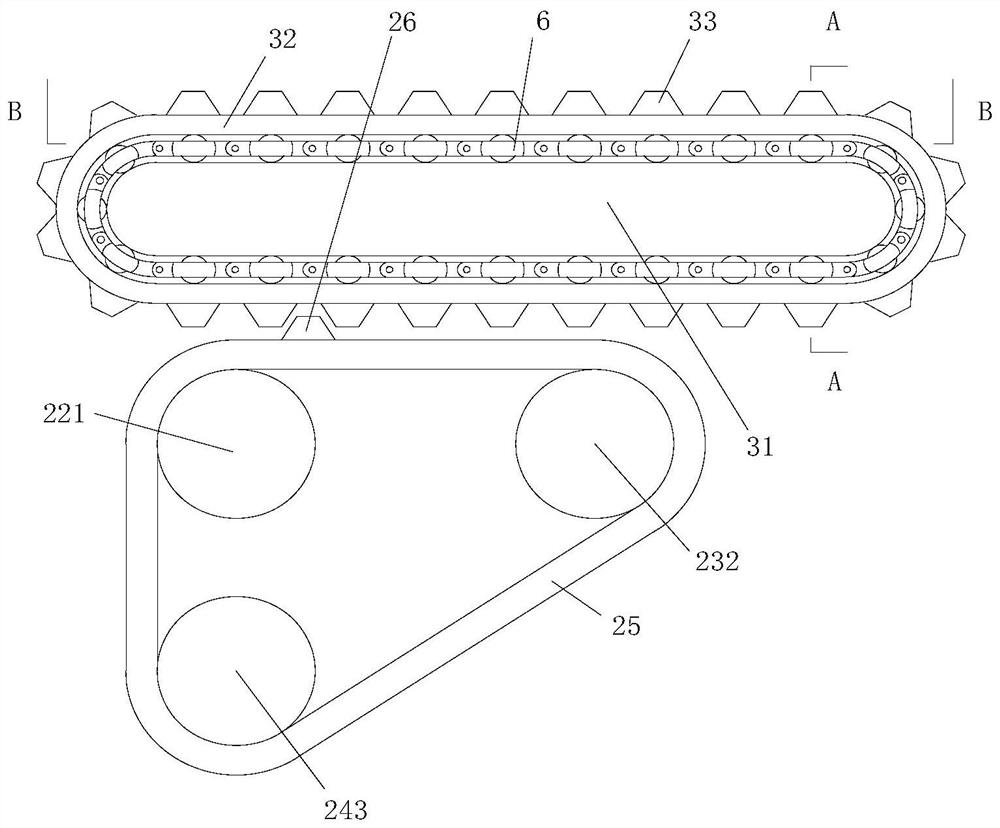

[0030] see Figure 1-8 , a punch body with a protective device that can automatically feed, including a punch body 1, a feed body is fixed on the punch body 1, and the feed body includes a driving mechanism 2 and a transmission mechanism connected to the driving mechanism 2 3; the driving mechanism 2 includes a driving block 21, the first driving shaft 22 is rotatably installed on the driving block 21, the first driving roller 221 is fixedly installed on the first driving shaft 22, and the first sliding roller 221 is also provided on the driving block 21. Groove 211 and the second chute 212, the first chute 211 is arranged horizontally, the inside of the first chute 211 is slidably installed with the first slide block 23, the inside of the first slide block 23 is rotatably installed with the second drive Shaft 231, the second drive shaft 231 is also fixed with the second drive roller 232, the first slide block 23 is rotatably equipped with a screw mandrel 233, the screw mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com